Boat Docking Ropes: Secure Your Boat with Confidence

Your boat docking ropes are far more than simple cords; they're the single most important piece of safety equipment protecting your vessel from damage at the pier. Choosing the right material, thickness, and length is a decision every boat owner has to get right. It's what keeps your investment secure against tides, wind, and the inevitable bump against the dock.

Why the Right Dock Ropes Are Your Boat's Best Insurance

Staring at a wall of ropes at the chandlery can feel a little overwhelming, but this choice is one of the most important you'll make. The best way to think about your dock ropes isn't as simple accessories, but as your boat's first and most active line of defense. They're a dynamic insurance policy you manage every single time you approach the pier.

For anyone planning serious cruising adventures in the Kimberley or even just navigating a busy local marina, understanding this is paramount. The quality of your dock lines can be the only thing standing between you and a very costly repair bill.

The Core Factors of Rope Performance

The performance of this "insurance policy" really boils down to three things: the rope's material, its diameter, and its elasticity. Each one plays a unique role in how the rope behaves under stress. Get any one of these wrong, and you're setting yourself up for potential failure.

Think of it this way: Using a thin, weak rope to hold a large boat is like trying to stop a car with a bicycle brake. It’s not a matter of if it will fail, but when. The forces involved are immense, and underestimating them can have serious consequences.

A quality dock line is specifically engineered to absorb the shock of a boat being pushed around by wind and waves. This controlled stretch, or elasticity, is what prevents the sudden, jarring shock loads that can snap a line or, worse, rip a cleat right off your boat. This is precisely why the material and construction are so vital.

More Than Just a Rope

Ultimately, the goal is to create a secure, yet flexible, connection that adapts to whatever the conditions throw at it. Your boat is almost never perfectly still, even when tied up. It rises and falls with tides, and it surges and sways with passing wakes and wind gusts.

Your dock lines need to be strong enough to hold fast but have enough give to absorb all that movement without breaking. This guide will walk you through everything you need to know about these critical tools.

We'll dive into these key areas so you can choose with complete confidence:

- Material and Construction: Understanding why materials like nylon are the gold standard and how braided or twisted ropes perform differently.

- Sizing and Length: Simple rules of thumb for matching rope diameter and length to your specific boat.

- Essential Knots: Mastering the handful of knots that give you maximum security and are easy to tie, even under pressure.

Choosing the right boat docking ropes is a non-negotiable part of being a responsible skipper. When you invest in the right lines and know how to use them, you’re actively protecting your boat, your peace of mind, and your wallet.

Quick Guide to Selecting Your Dock Ropes

To help you get started, this table summarizes the key decisions you'll need to make when outfitting your boat.

| Consideration | Why It Matters | Key Material/Type |

|---|---|---|

| Material | Determines elasticity, strength, and resistance to UV rays, chafe, and saltwater. | Nylon (for stretch and strength) |

| Construction | Affects handling, stretch, and how it wears over time. | Double Braid or Three-Strand Twist |

| Diameter | Must be strong enough for the boat's weight and windage, but not too stiff. | Match to boat length (e.g., 1/2" for 25-35 ft) |

| Length | Needs to be long enough for various docking situations without being unmanageable. | 2/3 boat length for bow/stern; full length for springs |

| UV Resistance | Prevents the sun from degrading the rope fibers, which weakens the line. | Look for UV-treated nylon or polyester |

| Chafe Gear | Protects the rope from abrasion where it rubs on the dock, chocks, or fairleads. | Add chafe guards to high-wear areas |

This quick-reference guide should give you a solid foundation. Remember, your dock lines are a system, and every component needs to be chosen with care to ensure your boat stays safe and sound.

Choosing Your Rope Material and Construction

Picking the right material for your dock lines is a lot like choosing the right tires for your car. What they're made of has a direct impact on safety, how they perform, and how long they'll last. The marine environment is incredibly harsh, and not just any rope can stand up to the abuse, so understanding the differences is the first step to tying up with confidence.

The global market for boat ropes is huge—around USD 1.2 billion—which tells you just how critical this gear is. Synthetic fibers completely dominate the industry, with about 75% of ropes being made from materials like nylon and polypropylene. Boaters love them for their incredible strength and resistance to UV rays and saltwater.

Let's break down the three most common synthetic fibers you'll find when shopping for new dock lines.

The Big Three Rope Materials

The material you choose affects everything from a rope's raw strength to its ability to absorb the shock of a bouncing boat. Each one has a specific job it's good at, but for general docking, there's one clear winner.

-

Nylon: This is the undisputed champion for dock lines. Its superpower is elasticity; nylon can stretch up to 15-20% of its length without damage. This stretch acts like a natural shock absorber, protecting your boat's cleats and other hardware from the violent, jarring forces of wind and waves. On top of that, it's incredibly strong, durable, and easy to handle.

-

Polyester: Think of polyester as nylon's less-stretchy cousin. It has fantastic strength and is even better than nylon at resisting UV damage and abrasion. However, its low-stretch personality makes it a poor choice for bow and stern lines where you need that give. That same quality, though, makes it perfect for jobs where you want minimal stretch, like spring lines or even for certain anchors for boats.

-

Polypropylene: This stuff is incredibly lightweight and has one very specific trick up its sleeve—it floats. While that sounds useful, polypropylene is much weaker than nylon or polyester and breaks down very quickly in the sun. Its low melting point and poor chafe resistance make it a terrible choice for any high-load job like docking. It’s best left for light-duty tasks like a heaving line or a water ski rope.

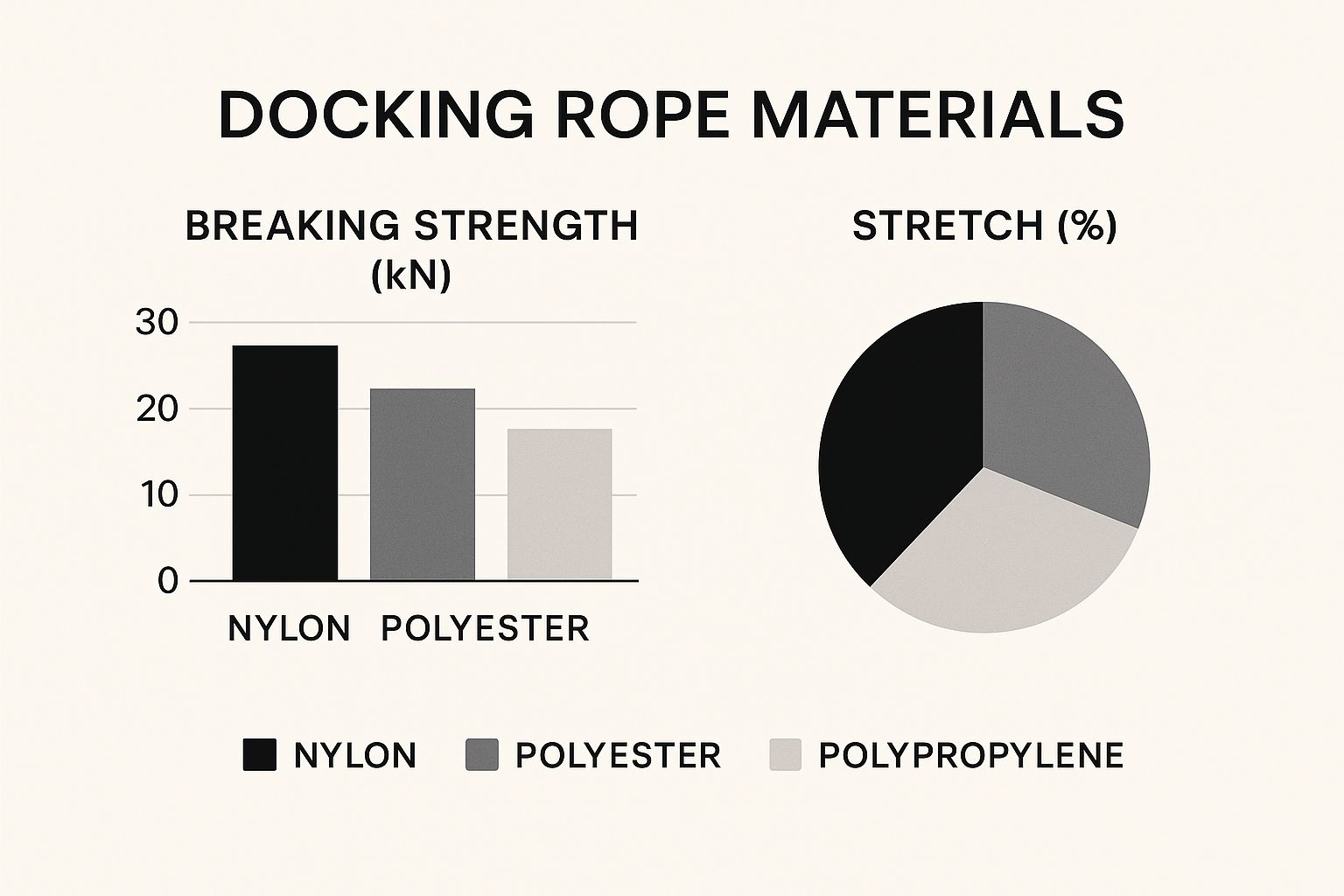

This chart shows a great visual breakdown of the key differences between these materials.

As you can see, nylon really hits the sweet spot with its blend of strength and shock-absorbing stretch, which is exactly why it’s our top pick for primary dock lines.

Picking the right material is a huge part of the puzzle. To help you weigh the pros and cons at a glance, here’s a quick comparison.

Comparing Common Dock Rope Materials

| Material | Strength | Stretch (Shock Absorption) | UV Resistance | Best Use Case |

|---|---|---|---|---|

| Nylon | Excellent | Excellent (High Stretch) | Good | Primary dock lines (bow/stern), anchor lines |

| Polyester | Excellent | Poor (Low Stretch) | Excellent | Spring lines, control lines, rigging |

| Polypropylene | Poor | Poor (Low Stretch) | Poor | Heaving lines, ski ropes, dinghy painters |

Ultimately, while polyester and polypropylene have their moments, nylon remains the go-to for the crucial job of securing your boat to the dock.

Understanding Rope Construction

Beyond the material itself, the way a rope is actually built—its construction—plays a huge part in how it feels in your hands, how it performs under load, and how long it will serve you. The two constructions you'll see most often are the classic three-strand twist and the more modern braided style.

A rope's construction is like a building's architecture. Both can use the same materials, but the design dictates how the structure handles stress, weather, and daily use.

When you're choosing, you're really just balancing how it handles, its durability, and what you're willing to spend.

Three-Strand Twist

This is the classic, old-school rope you probably picture in your head. It’s made from three large strands of fiber twisted together into one line. It’s simple, effective, and has been used for centuries for a reason.

- Pros: It’s the most affordable option out there and gives you great stretch, especially when it’s made of nylon. It’s also incredibly easy to splice, which is perfect for adding your own eye loops.

- Cons: It has a tendency to kink and hockle (unravel under load) if you don't handle it right. It can also get a bit rough on the hands over time compared to a smooth braided line.

Braided Ropes

Braided lines look and feel more modern because of their more complex construction, which gives them a completely different set of pros and cons. You’ll mainly encounter two types.

-

Double Braid: This is essentially a "rope within a rope." It has a braided inner core that provides most of the strength, which is then protected by a separate braided outer jacket. This design makes it incredibly strong, very comfortable on the hands, and highly resistant to abrasion. For many, double braid nylon is the absolute premium choice for dock lines.

-

Solid Braid: This style features a single, solid weave. While it’s nice and flexible and doesn’t kink easily, it’s not nearly as strong as double braid or three-strand. It also can't be spliced. It's best used for lighter-duty applications, like on a flag halyard or a tie-down for your canoe.

For most boaters, the ideal combination for general-purpose dock lines is either double braid or three-strand nylon. They give you that critical blend of strength, shock absorption, and durability you need to keep your boat safe and sound at the dock.

How to Select the Right Rope Size and Length

Choosing the right size and length for your boat docking ropes is one of those fundamental skills that directly impacts your safety and peace of mind at the dock. It’s all about simple physics. A line that’s too thin can snap under load, and one that’s too short is useless half the time.

Getting these two measurements right isn't just a recommendation; it's what prepares you for a smooth, secure tie-up every single time you come alongside the pier. The two key dimensions to nail down are the rope's diameter (its thickness) and its overall length. These aren't just random numbers—they are directly tied to your boat's size and weight.

Matching Rope Diameter to Your Boat

The diameter of your dock line is what gives it its breaking strength. It's easy to think a thicker rope is just a little stronger, but it actually provides a much greater safety margin against the powerful forces of wind and current. A good rule of thumb is to go up in diameter every few feet of boat length.

Using a rope that’s too thin is one of the most common—and dangerous—mistakes a skipper can make. It creates a weak link in your docking setup that’s just waiting to fail at the worst possible moment.

The right diameter acts as your shock absorber. It ensures the rope can handle not just the dead weight of your boat, but also the sudden, immense loads from a passing wake or a strong gust of wind without snapping.

Boaters have developed a time-tested formula to make this super simple. Just follow this guide to match your rope diameter to your boat's length:

- For boats up to 27 feet: Use 3/8-inch diameter rope.

- For boats 28 to 35 feet: Use 1/2-inch diameter rope.

- For boats 36 to 45 feet: Use 5/8-inch diameter rope.

- For boats 46 to 54 feet: Use 3/4-inch diameter rope.

When in doubt, always go one size up. The extra cost is tiny compared to the peace of mind and potential repair bills you're avoiding. For an even more detailed breakdown, you can check out our comprehensive dock line size chart to find the perfect fit.

Calculating the Perfect Rope Length

Once you've got the diameter sorted, the next step is figuring out the right lengths. You’ll need different lengths for different jobs. Your main lines are the bow lines, stern lines, and spring lines, and each one has its own ideal length.

Bow and Stern Lines: These are your go-to lines for securing the front and back of the boat. A great rule is to have them be about two-thirds of your boat’s total length. This gives you plenty of line to work with at most docks without a mess of extra rope cluttering up your deck.

Spring Lines: These are the real heroes for stopping your boat from surging forward or backward along the dock. Spring lines need to be longer, ideally matching the full length of your boat. This lets you run them from a bow cleat way back on the dock, or from a stern cleat far forward, giving you maximum stability.

Let's walk through a real-world example to see how this all comes together.

Example Sizing for a 32-Foot Boat

Imagine you have a 32-foot cabin cruiser. Here’s how you’d build out your dock line inventory based on these guidelines.

- Diameter: At 32 feet, your boat falls into the 28-35 foot range. You'd want to go with a 1/2-inch diameter rope for all your main lines.

- Bow & Stern Lines: Two-thirds of 32 feet is about 21 feet. A standard 25-foot pre-made line is the perfect choice for your two bow lines and two stern lines.

- Spring Lines: For spring lines, you need them to be as long as your boat. You'd buy two 35-foot lines for this, which gives you a little extra length to play with.

Your complete set of dock lines would include four 25-foot lines and two 35-foot lines, all with a 1/2-inch diameter. With this setup, you’re ready for just about any docking situation you'll face.

Mastering The Three Essential Docking Knots

Docking a boat can feel like the final, high-pressure exam at the end of a great day on the water. But what if you could turn that stress into a smooth, confident maneuver? The secret is mastering a few essential knots. Think of them as the language you use to communicate with your boat docking ropes—and the dock itself.

Knowing the right knot for the right situation is what separates a rookie from a seasoned skipper. You don't need a mental library of dozens; you just need to build solid muscle memory for the three most important ones. Let's walk through the "how," "why," and "when" for each, so you can tie up safely and get on with your day.

The Cleat Hitch: Securing To A Cleat

This is the bread and butter of boating knots. It’s the one you'll use every single time you tie up to a standard dock cleat. The Cleat Hitch is brilliant because it secures a line to a cleat on your boat or the dock quickly and reliably. Its real beauty? It holds fast under immense strain but can be released in seconds, even with tension on the line.

Getting this one right is absolutely non-negotiable for safe docking.

- Start with a Turn: Take one full turn around the base of the cleat, going under both horns. This first wrap takes the brunt of the load.

- Cross Over: Bring the working end of the rope diagonally across the top of the cleat, starting a figure-eight pattern.

- Wrap Under: Loop the line under the opposite cleat horn. You should now clearly see a figure-eight taking shape.

- Finish with a Locking Hitch: Make one more crossing turn, but this time, tuck a small loop of the line under the crossover itself and pull it snug.

A common mistake is getting fancy and adding extra loops. A correctly tied Cleat Hitch is simple and clean. Anything more just creates a mess that will be a nightmare to untie later.

The Bowline: The Go-To For A Fixed Loop

The Bowline (pronounced "boh-lin") is often called the "king of knots," and for good reason. It creates an incredibly reliable fixed loop at the end of a line that absolutely will not slip or jam, no matter how much strain you put on it. Better yet, even after being pulled tight, it remains surprisingly easy to untie.

This makes it the perfect knot for creating a loop to toss over a piling, post, or mooring ring.

The Bowline is your go-to whenever you need a temporary, secure loop that you can trust completely. Its strength and reliability are legendary among sailors and boaters.

Many skippers learn this one with the simple "rabbit" mnemonic:

- Make the Hole: Create a small overhand loop in the standing part of the rope. This is the "rabbit hole."

- Rabbit Comes Up: Pass the working end (the "rabbit") up through the hole from behind.

- Around the Tree: Wrap the working end around the standing part (the "tree").

- Back Down the Hole: Pass the working end back down through the original loop you made.

- Pull Tight: Hold onto the loop and the standing part while pulling the working end to tighten the knot securely.

Mastering the Bowline is a critical skill that directly contributes to knowing how to dock a boat safely in all kinds of situations.

The Round Turn And Two Half Hitches: For Pilings And Rings

So, what do you do when there isn't a cleat in sight? When you need to tie up to something like a large piling or a thick metal ring, this knot is your best friend. The "Round Turn and Two Half Hitches" is simple, strong, and highly resistant to chafing because the first full turn spreads the load over a wider area of the rope.

The name might sound complicated, but it's really just two easy steps put together.

-

The Round Turn: This is the most important part. Take the working end of your line and make a full 360-degree wrap around the piling or ring. This first turn is the workhorse—it absorbs most of the friction and strain, protecting the actual knot from wearing out.

-

The Two Half Hitches: Now, you just have to lock it in. Tie two identical overhand knots (called half hitches) around the standing part of the line to secure the end. For the first half hitch, pass the end over and around the standing line, then through the loop you just created. Repeat that exact same motion for the second hitch.

Pull everything snug, and you've got an exceptionally secure connection. This knot is a fantastic, practical alternative to the Bowline for tying to posts and rings, especially when you need something that's easy to adjust.

Extending the Life of Your Docking Ropes

Your boat docking ropes are a serious investment in your boat's safety. Just like any other critical piece of gear on board, they need some basic care to perform at their best. A simple, consistent maintenance routine can add years to their lifespan, saving you money and giving you peace of mind that they'll hold fast when you need them most.

Proper care really starts with keeping them clean. When salt water dries, it leaves behind tiny salt crystals that act like microscopic knives inside the rope's fibers, slowly sawing away at its strength. Grit and sand from the dock do the same kind of damage. Most of the time, a good rinse with fresh water is all they need.

For a deeper clean, you can soak your lines in a bucket of fresh water with a splash of mild, boat-safe soap. Give them a gentle swirl, then rinse them thoroughly until every bit of soap is gone. Some boaters even toss their ropes into a mesh laundry bag and run them through the washing machine on a gentle cycle—no detergent, of course. Whatever you do, make sure they air-dry completely before you put them away.

Smart Storage and Regular Inspections

Sunlight is the silent killer of synthetic ropes. Those UV rays are relentless, attacking the fibers and causing them to become brittle and weak over time. Honestly, one of the best things you can do to preserve their strength is to simply store them out of the sun.

When you're not tied up, stow your ropes in a dedicated locker, a rope bag, or just toss them below deck. This protects them from UV rays, dirt, chemicals, and getting stepped on. This one simple habit can easily add years to the life of your dock lines.

A well-maintained rope is a predictable rope. By inspecting your lines regularly, you transform a potential point of failure into a known quantity, giving you confidence every time you tie up.

A quick visual and hands-on inspection should be part of your routine before you leave the dock. Run your hands along the length of each rope, feeling for anything that seems off.

What to Look For During an Inspection:

- Chafe: Look for fuzzy, worn sections where the rope has been rubbing against the dock, a piling, or a fairlead on your boat.

- Fraying or Cuts: Any obvious cuts or areas where strands are broken are a major red flag. This seriously weakens the rope.

- Stiffness or Discoloration: A line that feels stiff, hard, or looks faded has likely suffered major UV damage and lost a lot of its stretch and strength.

If you find a rope with any of these issues, it’s time to retire it. Don't trust it as a primary dock line anymore.

Pro Tips for Maximum Rope Longevity

Beyond the basics of cleaning and storage, a few pro tricks can help you get the absolute most from your dock ropes. These strategies are all about distributing wear and protecting your lines where they're most vulnerable.

One of the best things you can do is use chafe guards. These are just tough sleeves made of leather, rubber, or heavy-duty nylon that you slide over the rope at high-wear spots, like where it passes through a chock. This sacrificial layer takes all the abuse, saving your rope from damage.

Another great tip is to periodically reverse your lines end-for-end. This simple move ensures the same section isn't always taking the strain at the cleat or piling, which can effectively double the rope's working life.

This is especially important for lines like permanent mooring ropes, which are under constant stress in some pretty dynamic conditions. The growing demand for these heavy-duty ropes in global shipping and port operations highlights just how vital they are to maritime safety; you can discover more insights about this market on Expert Market Research.

Your Dock Rope Questions, Answered

Even after you've got a handle on the materials and knots, there are always those lingering, practical questions about boat docking ropes. Getting straight answers to these common queries is what really builds confidence, ensuring you make the smartest, safest choices for your vessel.

Let's dive into the questions we hear most often from boaters just like you—the real-world concerns that pop up right when you're at the chandlery or prepping for a weekend on the water.

Should I Buy Dock Ropes With a Pre-Spliced Eye?

For almost every boater out there, the answer is a definite yes. A professionally spliced eye loop is in a different league of strength compared to a knot. A knot can slash a rope's breaking strength by as much as 50%, but a proper splice holds onto 90-95% of the rope's original power.

Think about it: that built-in loop makes tying up to a cleat incredibly fast and secure. When you're trying to dock with a bit of wind pushing you around, you'll be thankful you're not fumbling to tie a perfect Bowline under pressure.

A pre-spliced eye is like having a perfectly engineered connection point, ready to go at a moment's notice. It takes one more variable out of the docking equation, which makes the whole process simpler and safer.

How Many Dock Lines Do I Actually Need?

The right number really comes down to your boat's size and your usual docking spots. But for most boats under 40 feet, a set of four to six lines is the sweet spot. This gives you a rock-solid foundation for nearly any situation you'll encounter.

A great starting inventory looks like this:

- Two Bow Lines: To hold the front of the boat.

- Two Stern Lines: To lock down the back.

- Two Spring Lines: To stop the boat from surging forward or backward.

Tossing a couple of extra lines of different lengths into a locker is also a brilliant move. You never know when they'll be a lifesaver for navigating an unfamiliar dock, handling a tricky slip, or just adding peace of mind in rough weather.

How Do I Know When It's Time to Replace My Ropes?

Think of your dock lines as essential safety gear that wears out over time. Knowing when to retire them is a crucial judgment call. Give your ropes a good inspection regularly, looking for any signs of wear that could spell trouble.

You should replace your boat docking ropes immediately if you see any of these red flags:

- Serious Chafe: Look for spots that are fuzzy, worn thin, or have that frayed, "hairy" look.

- Discoloration or Stiffness: If a rope feels hard and crunchy or has faded badly, it's likely a victim of UV damage. The fibers have become brittle and lost their all-important stretch.

- Cuts or Melted Spots: Any visible nicks, cuts, or places where friction has melted the fibers together are critical weak points.

- Permanent Stretching: If a section of rope feels noticeably thinner after being under a heavy load, it has been permanently weakened and can't be trusted.

Can I Use the Same Ropes for Docking and Anchoring?

We strongly recommend against it. Dock lines and anchor lines (also called anchor rodes) are designed for completely different jobs and have unique requirements.

Anchor lines have to be much, much longer to achieve the proper "scope"—the ratio of line length to water depth—which is what allows an anchor to dig in and hold. They're also often a mix of rope and chain. Trying to use a shorter dock line for anchoring is simply unsafe; it's very unlikely to hold your boat securely.

For a complete selection of premium, durable dock lines designed to protect your investment, trust the experts at Better Boat. Our ropes are crafted from high-quality, UV-treated nylon to provide the strength and shock absorption you need for secure, worry-free docking. Explore our full range of docking and anchoring solutions at https://www.betterboat.com and tie up with confidence.