The Ultimate Guide to Boat Trailer Brakes

Boat trailer brakes are the unsung heroes of safe towing. They're a critical system designed to help your tow vehicle handle the combined weight of your boat and trailer, ensuring you can stop safely and predictably.

Most states legally require them for trailers over a certain weight—typically around 3,000 pounds—and for good reason. They are absolutely essential for preventing accidents, especially on steep grades or during sudden stops.

Why Your Boat Trailer Brakes Are Mission Critical

Picture this: you're easing down a steep, slick boat ramp. As you descend, you can feel the massive weight of your rig pushing your truck forward, putting its own brakes to the ultimate test. It’s in moments like these that the true value of a good set of trailer brakes becomes crystal clear. They aren't just an accessory or a legal box to check; they're your primary defense against a dangerous loss of control.

Think about it—your tow vehicle's brakes were engineered to stop its own weight, plus maybe a few passengers and some gear. They were never designed to handle the thousands of extra pounds a boat and a trailer and all its components - such as trailer winches, bunks, and more - add to the equation.

Without a separate braking system on the trailer itself, you're looking at a recipe for brake fade, dangerously long stopping distances, and even catastrophic failure.

Understanding the Forces at Play

When you're towing, you're dealing with a huge amount of momentum. A heavy boat can easily overwhelm your truck's ability to slow down, especially on downhill stretches or in an emergency. This is exactly where your trailer's brakes come in, sharing the workload to keep your stop stable and controlled. Properly functioning trailer brakes help prevent some seriously scary situations:

- Jackknifing: This is when the trailer swings out to the side during a hard stop, forming a "V" with your tow vehicle. It's incredibly dangerous and difficult to recover from.

- Trailer Sway: Uncontrolled side-to-side movement, often caused by crosswinds or improper weight distribution, can quickly escalate and lead to a total loss of control. Brakes can help manage it.

- Overheating Vehicle Brakes: Making your truck's brakes do all the work can cause them to overheat, smoke, and ultimately fail when you need them most.

The industry is taking towing safety more and more seriously. The global boat trailer market was valued at about USD 1.15 billion in 2025 and is projected to hit approximately USD 1.70 billion by 2032. This growth shows a clear demand for safer, more reliable equipment, with advanced brake systems leading the charge. You can dig deeper into these market trends and their impact on safety regulations to see where things are headed.

Your trailer’s brakes are the critical link that transforms a nerve-wracking tow into a confident, safe journey. They give you the peace of mind to focus on the fun ahead, not the dangers of the road.

Ultimately, investing in and maintaining high-quality boat trailer brakes is about protecting your boat, your truck, and everyone else on the road. It’s the bedrock of responsible, stress-free boat ownership.

How Different Trailer Braking Systems Work

To really get why trailer brakes are so crucial for protecting your investment, it helps to understand what’s going on mechanically. The technology might sound intimidating, but the basic ideas are surprisingly simple. We're going to break down the two main players—hydraulic surge and electric-over-hydraulic—and make it all crystal clear.

Both systems have the same job: stopping your trailer safely. But they go about it in completely different ways. One is a purely physical system that works off momentum, while the other is a high-tech setup that uses precise electrical signals. Getting this difference is the key to picking the right brakes for your boat and your towing style.

Hydraulic Surge Brakes: The Power of Momentum

Picture a beefed-up shock absorber built right into your trailer’s tongue. That's pretty much the core concept of a hydraulic surge brake system. It’s a slick, self-contained unit that uses the trailer’s own forward momentum to apply the brakes. No wires, no connections to your truck’s fancy brake controller—it’s all pure physics.

The whole thing kicks into gear when you slow down. When you hit the brakes in your truck, the trailer naturally wants to keep going, pushing forward against the hitch. This "surge" is what does the work, compressing a hydraulic cylinder called an actuator that lives inside the coupler.

Here’s how it plays out, step-by-step:

- You Hit the Brakes: The moment you slow your truck, the process begins.

- The Trailer Surges: The trailer's momentum pushes into the tow vehicle, squeezing the surge actuator.

- Pressure Builds: That squeeze pressurizes brake fluid inside the actuator's master cylinder.

- Brakes Engage: The pressurized fluid shoots through brake lines down to the wheels, forcing the brake pads to clamp onto the rotors. This friction is what slows the trailer.

The real beauty of a surge system is its elegant simplicity. It’s completely proportional. A light tap on your brakes leads to gentle trailer braking, while a panic stop creates a powerful, immediate response.

As soon as you take your foot off the brake and get back on the gas, the pressure on the actuator lets up, and the trailer brakes disengage. The trailer is essentially braking itself in direct response to what your truck is doing.

Electric-Over-Hydraulic Brakes: The Precision of Electronics

Now let’s talk about the more advanced option. Think of Electric-Over-Hydraulic (EOH) brakes as being like the sophisticated anti-lock braking system (ABS) in your car. Instead of using raw momentum, an EOH system uses a precise electrical signal to deliver immediate and incredibly controllable stopping power.

This system is the best of both worlds, pairing the raw strength of hydraulic brakes at the wheels with the pinpoint accuracy of an electronic signal coming right from the driver's seat. To make it work, you’ll need an in-cab electric brake controller. When you hit the brakes, this controller sends a signal back to an electric-hydraulic actuator mounted on the trailer.

Here's the chain of events for an EOH system:

- Signal Sent: You touch the brakes, and the in-cab controller instantly zaps an electrical signal back to the trailer.

- Actuator Wakes Up: An electric pump inside the trailer's EOH actuator gets the signal and springs to life.

- Pressure Builds Fast: The pump pressurizes the brake fluid. Critically, the amount of pressure it creates is directly tied to the signal strength from your controller. More signal, more pressure.

- Brakes Apply: Just like the surge system, that pressurized fluid travels to the calipers and clamps the pads onto the rotors, stopping you on a dime.

This setup gives you an incredible amount of control. You can fine-tune the braking force on the fly with the controller and even apply the trailer brakes by themselves—a game-changer for correcting trailer sway on the highway. EOH systems give you almost zero delay, eliminating that slight lag you sometimes feel with surge brakes.

Surge Brakes vs. Electric Brakes: A Head-to-Head Comparison

Choosing between hydraulic surge brakes and electric-over-hydraulic (EOH) brakes is one of the biggest calls you'll make for your boat trailer. This isn't just about stopping power. It’s about control, maintenance, and matching the right tech to your specific towing needs. This decision affects everything from navigating a tight boat ramp to cruising down the highway with total confidence.

Both systems will get the job done, but they work on fundamentally different principles. Surge brakes are a self-contained, mechanical marvel. EOH systems, on the other hand, bring the precision of modern electronics into the mix. Let's dive deep into a head-to-head comparison to see which one is the right fit for your rig.

The Simplicity of Surge Brakes

Hydraulic surge brakes are the classic workhorse of the boat trailer world. Their main advantage? Pure simplicity.

The entire system is housed right on the trailer and activates based on momentum, meaning you don't need a special electronic controller in your tow vehicle. This "plug-and-play" nature makes them incredibly versatile—you can tow your trailer with pretty much any capable vehicle without needing extra wiring or setup.

This simplicity also means reliability, especially in the harsh marine environment. With fewer electronic parts, there are fewer things that can fail from water getting in or corrosion setting up shop. For many boaters, especially those with lighter boats used mostly in freshwater, the straightforward and dependable performance of surge brakes is all they'll ever need.

Of course, this mechanical simplicity has its drawbacks. Surge brakes can sometimes feel less responsive, with a small but noticeable delay between when you hit the brakes and when the trailer brakes actually kick in. They also can’t be activated separately from the tow vehicle, which means you can't use them to manually straighten out a swaying trailer.

Backing up, particularly up a hill, is another common pain point. The system can’t tell the difference between braking momentum and the pressure from reversing, so it tries to lock up the brakes. Most modern surge systems have a lockout solenoid to prevent this, but it’s an extra thing to think about.

The Precision Control of Electric-Over-Hydraulic (EOH) Brakes

If surge brakes are the reliable old workhorse, then EOH systems are the high-performance thoroughbred. By combining the raw stopping power of hydraulics with the instant response of an electronic signal, EOH brakes deliver a superior level of control and safety.

An in-cab controller lets you adjust braking intensity on the fly, tailoring the trailer's response to changing road conditions or different load weights. This level of control is a total game-changer. The braking is immediate and proportional, which gets rid of the lag you feel in surge systems and creates a much smoother, more connected towing experience.

The ability to manually apply the trailer brakes independently is perhaps the single greatest safety advantage of an EOH system. If you ever feel trailer sway starting to develop, a light touch on the manual override can straighten things out quickly and safely.

Naturally, this advanced performance comes with a bigger price tag. EOH systems are significantly more expensive than surge brakes and require a more involved installation.

Your tow vehicle has to be equipped with a compatible in-cab brake controller, and the system has more wiring that needs to be carefully protected from the elements. This added complexity also means more potential points of failure, especially if it isn't installed or maintained correctly.

Hydraulic Surge Brakes vs. Electric-Over-Hydraulic (EOH) Brakes

When you lay it all out, the choice comes down to your budget, your tow vehicle, and how much control you want. Here’s a quick side-by-side look at the two systems.

| Feature | Hydraulic Surge Brakes | Electric-Over-Hydraulic (EOH) Brakes |

|---|---|---|

| Activation | Mechanical (trailer's forward momentum) | Electronic signal from an in-cab controller |

| Control & Responsiveness | Slight delay, less precise control | Instant and proportional braking, highly adjustable |

| Installation | Simple, self-contained on the trailer | Complex, requires an in-cab controller and vehicle wiring |

| Cost | Lower initial cost | Higher initial cost |

| Safety Features | Basic braking | Manual override for sway control, adjustable braking |

| Maintenance | Simpler, fewer components to fail | More complex, requires checking both hydraulic and electrical parts |

| Versatility | Can be towed by any capable vehicle without modification | Requires a tow vehicle equipped with a brake controller |

| Best For | Lighter boats, occasional use, budget-conscious owners | Heavier boats, long-distance towing, owners prioritizing control |

Each system has its place. For a simple setup that just works, surge brakes are hard to beat. But for the ultimate in safety and a smooth, controlled ride, EOH is the clear winner.

Maintenance and Durability Showdown

Maintenance is a huge factor, especially for boat trailers that get dunked in water all the time—and especially saltwater.

- Surge Brakes: These systems are pretty easy to maintain. The main tasks involve checking brake fluid levels, bleeding the lines to get rid of air and moisture, and inspecting pads and rotors for wear.

- EOH Brakes: Maintenance on the hydraulic parts is similar to surge brakes. However, you also have electrical components to worry about, including wiring, connections, and the actuator unit itself. Keeping these connections clean and free of corrosion is absolutely vital for reliable operation.

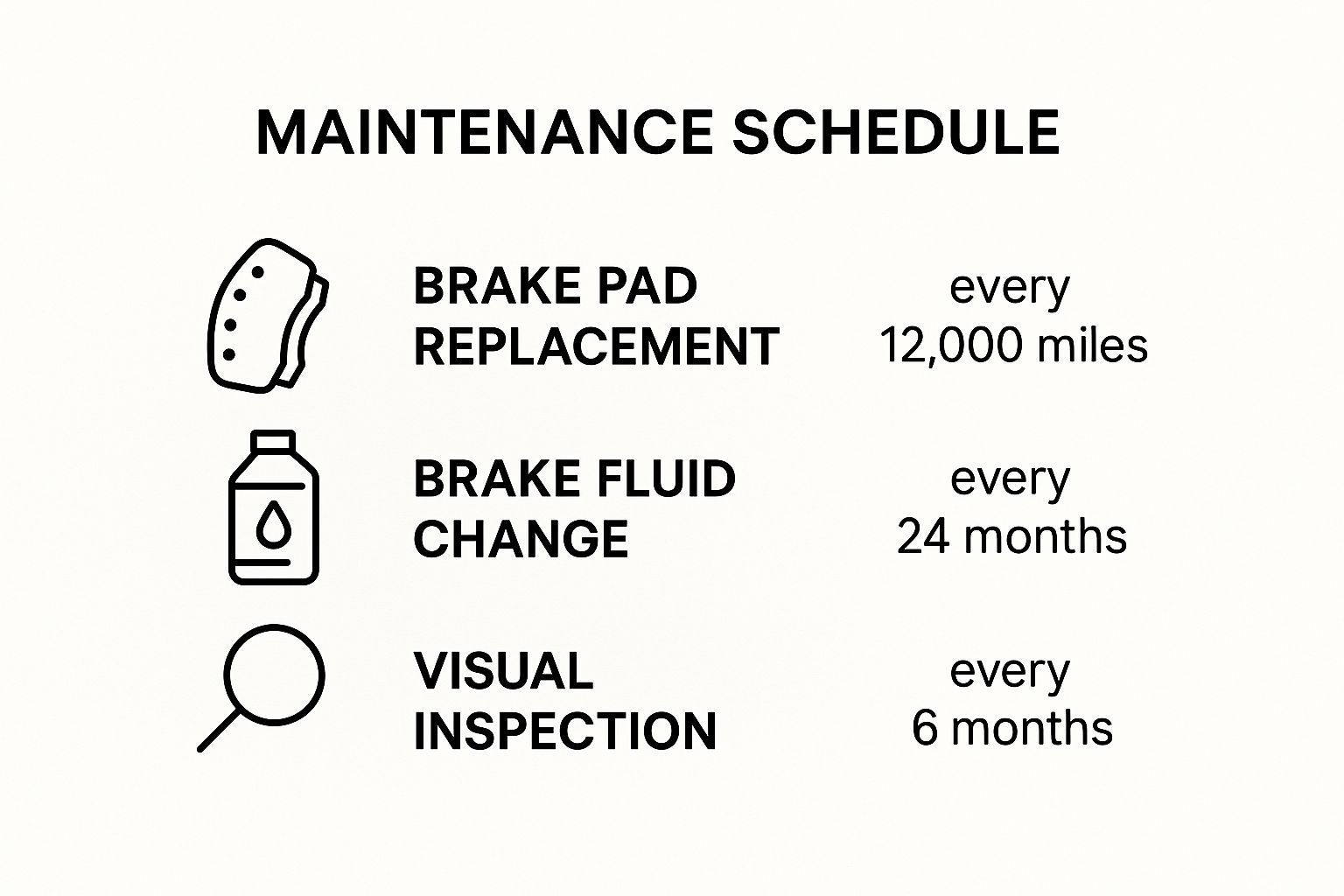

The infographic below outlines a standard maintenance schedule for both types of hydraulic boat trailer brakes.

This guide shows that while the core tasks are similar, being diligent is the key to making sure your brakes work when you need them. For a complete guide to upkeep, especially during the offseason, check out our guide on winterizing a boat for cold weather care, since proper storage is crucial for the life of your brakes.

How to Choose the Right Brakes for Your Boat Trailer

Picking out the right brakes for your boat trailer isn't just about checking a box on an options list. It’s about matching the right tech to your real-world needs.

The wrong choice can lead to some seriously white-knuckle moments on the road, or worse, a complete failure when you need to stop now. The goal here is simple: invest in a setup that gives you confident, no-drama stopping power every single time.

This decision goes way beyond a simple "surge vs. electric" debate. You have to take a hard look at your boat's fully loaded weight, where you'll be towing, and what the law says. A heavy offshore fishing rig has a completely different set of needs than a little freshwater skiff.

Start with Your Boat’s Loaded Weight

The absolute number-one factor in this whole equation is the Gross Vehicle Weight Rating (GVWR). This isn't just what the boat weighs empty. It's the grand total: boat, motor, a full tank of fuel, water, all your gear, and the trailer itself. This number is your North Star.

Most states will legally require brakes on any trailer with a GVWR of 3,000 pounds or more, but you've got to check your local rules. Getting this wrong can mean big fines and even bigger risks.

- For Lighter Rigs (Under 4,000 lbs GVWR): You can often get by just fine with a basic, single-axle surge brake system using drum brakes. It’s a proven, cost-effective solution for smaller boats.

- For Mid-Weight Rigs (4,000 - 7,000 lbs GVWR): This is where performance really starts to count. I strongly recommend upgrading to disc brakes for their far superior stopping power and ability to handle heat. A heavy-duty surge system or a basic EOH setup is a very smart move here.

- For Heavy Rigs (Over 7,000 lbs GVWR): Don't even think about it—an electric-over-hydraulic (EOH) system with disc brakes on at least two axles is a must-have. The precise control and massive stopping force are non-negotiable for safely handling that kind of weight.

Consider Your Environment and Towing Style

Where you boat is just as critical as what you're boating with. The environment, especially saltwater, will make or break your braking system.

Saltwater is pure evil to metal parts. It will relentlessly attack standard steel, seizing up calipers and chewing through rotors in no time at all.

If you even think about launching in saltwater, do yourself a favor and invest in stainless steel or specially coated "saltwater-rated" brake components. Yes, it costs more upfront, but it'll save you a world of headache and money on constant repairs down the line.

Your towing habits matter, too. Do you live in the mountains and constantly deal with steep grades? Or are you always stuck in stop-and-go city traffic? Those situations scream for the immediate response of an EOH system.

But if you’re just making short, flat trips on quiet country roads, a quality surge brake system will probably do the job just fine. More and more boaters are opting for better brakes, which is why the global market is expected to jump from $500 million in 2025 to over $800 million by 2033, driven by safer tech like EOH. You can dig into the numbers in the full boat trailer brake market analysis to see where things are headed.

Match Brakes to Your Tow Vehicle

Finally, your truck has to play nice with your trailer brakes. A simple surge brake setup is the most universal—it doesn't require any special equipment on your tow vehicle at all.

An EOH system, however, is a different story. It absolutely requires an in-cab electric brake controller. Many newer trucks come with one from the factory, but if you have an older vehicle, you'll need to get one installed professionally. Without that controller, your fancy EOH brakes are just expensive dead weight.

Think of it this way: just as you'd never use the wrong anchor for your boat, you can't have a mismatch between your trailer brakes and your truck. It's all about creating a balanced, safe system. You can learn more about that principle in our guide on choosing the best boat anchors.

Essential Maintenance for Your Trailer Brakes

Your boat trailer brakes are only as reliable as their last check-up. Neglecting them is a bit like skipping a pre-flight inspection; everything seems fine right up until the moment it absolutely isn’t. Consistent, proactive upkeep is the only real way to guarantee your brakes will be there for you when you need them, protecting your investment and keeping you safe on the road.

It's best to think of brake maintenance as just another part of your boating routine, not a chore. You flush your engine and clean the hull, right? Well, caring for your brakes prevents those tiny, unseen issues from spiraling into catastrophic (and expensive) failures. A little attention after each trip and a more thorough look each season will keep your system running smoothly for years.

Your Seasonal Brake Maintenance Checklist

A simple routine makes all the difference. Instead of waiting for a grinding noise or a soft pedal to tell you something's wrong, a quick inspection at the start and end of each boating season can catch problems before they start. This is your first line of defense against normal wear and tear.

Here’s a practical checklist to get you started:

- Brake Fluid Check: Your system runs on clean, moisture-free fluid. Pop open the master cylinder reservoir. If the fluid is low, or worse, looks dark and murky, it’s time for a flush and refill.

- Visual Line Inspection: Get down and trace the hydraulic lines all the way from the actuator to each wheel. You're looking for any red flags—cracks, bulges, or signs of leaking fluid. Any of these mean a line needs to be replaced immediately.

- Pad and Rotor Wear: You can often peek right through the wheel spokes to check the brake pads. They should have a good amount of material left. While you're there, look at the rotors for any deep grooves or warping.

- Electrical Connections (for EOH): If you're running an electric-over-hydraulic system, these connections are a common trouble spot. Unplug them, check for any green or white crusty corrosion, and apply a dab of dielectric grease to keep them clean and conducting properly.

Proactive maintenance is all about prevention, not reaction. A 15-minute inspection in your driveway can easily save you from a multi-hour breakdown on the shoulder of a busy highway.

Following this simple list turns brake care from a daunting job into a few manageable steps. For a bigger picture, our guide to essential boat trailer maintenance tips covers everything from tires to lights, giving you a complete checklist for total trailer care.

The Battle Against Saltwater Corrosion

For a boat trailer, saltwater is public enemy number one. That salty, wet environment is brutally corrosive and it relentlessly attacks every metal part of your brake system, from the lines and fittings to the caliper pistons. A single launch in saltwater can start a countdown to brake failure if you don't take action.

The secret to winning this fight is simple: fresh water, and lots of it. Rinsing your brakes isn't just a good idea; it's mandatory after every single dip in the salt.

Your Post-Launch Rinse-Down Routine:

- Rinse Immediately: As soon as you can after pulling the trailer out of the water, grab a hose and give the entire brake assembly on each wheel a thorough spray-down with de-salt concentrate.

- Focus on Key Areas: Pay extra attention to the calipers, rotors, and the backs of the brake drums. You want to blast out any trapped salt that could sit there and eat away at the metal.

- Let It Air Dry: Letting the brakes air dry completely before you park the trailer for storage helps prevent moisture from getting trapped, which can speed up the rusting process.

This one simple act is the most effective thing you can do to prolong the life of your boat trailer brakes. Seriously.

Knowing When to Call a Professional

While you can handle most of the routine checks and cleaning yourself, some jobs are definitely better left to the pros. Bleeding hydraulic brake lines, for instance, can be a real headache. If you do it wrong, you can leave air bubbles trapped in the system, leading to a spongy pedal and dangerously weak stopping power.

Likewise, swapping out brake pads, rotors, or calipers requires the right tools and a good bit of mechanical know-how. If your inspection turns up significant wear, deep scoring on the rotors, or a caliper that's seized up, it's time to book an appointment with a qualified trailer mechanic. Don't risk your safety to save a few bucks—know your limits and trust an expert to get the job done right.

Troubleshooting Common Brake Problems

Even the best boat trailer brakes can throw a fit now and then. When they do, it's not just frustrating—it can bring your whole trip to a screeching halt before you even reach the ramp. Before you start bracing for a huge repair bill, you can often figure out what's wrong yourself with a little systematic troubleshooting.

I've laid out the most common issues in a simple symptom-cause-solution format. Knowing what to look for not only lets you handle small fixes on your own, but it also means you can have a much smarter conversation with your mechanic if you do need to call in a pro.

Brakes Feel Weak or Spongy

This is probably the most common—and nerve-wracking—brake problem you'll encounter. You hit the brakes, but the pedal feels mushy and the trailer just doesn't seem to be slowing down like it should.

Potential Causes and Solutions:

- Low Brake Fluid: This is always the first place you should look. If the master cylinder is low on fluid, the system simply can't build up enough hydraulic pressure to work properly. Solution: Top off the reservoir with the right brake fluid (your manual will tell you if it's DOT 3 or DOT 4). But remember, that fluid had to go somewhere. Be sure to check for leaks around the lines and fittings.

- Air in the Hydraulic Lines: This is what creates that classic "spongy" feeling. Unlike brake fluid, air bubbles compress easily, which kills your stopping power. Solution: The system needs to be bled to force all the air out. While you can do this yourself, it's a messy job that has to be done perfectly. For most people, it's worth having a professional handle it.

- Worn Brake Pads: Just like the brakes on your truck, trailer brake pads don't last forever. When they get too thin, there isn't enough material left to create the friction needed to stop the rotors. Solution: Take a look at the pads. If they're worn down to the little metal wear indicators, or you can see less than 1/8 inch of pad material, it's time for a new set.

Brakes Lock Up or Drag

Ever feel your trailer brakes grabbing hard when you're not expecting it, or refusing to let go after you've stopped? That's a dragging brake, and it's a serious problem that can chew up your tires and make the trailer dangerously unstable.

A dragging brake generates an incredible amount of heat. It can cook your wheel bearings in a hurry and even has the potential to start a fire. If you suspect a brake is dragging, pull over and fix it immediately.

Potential Causes and Solutions:

- Seized Caliper or Wheel Cylinder: Corrosion is the number one enemy here, especially if you're launching in saltwater. A caliper piston (on disc brakes) or a wheel cylinder (on drum brakes) can rust in place, locking the pads against the rotor or drum. Solution: Sometimes you can work a sticky caliper free, but more often than not, the only real fix is to replace the seized part.

- Faulty Surge Actuator: The slide mechanism inside a surge actuator can get gummed up with rust and grime, causing it to stick. When this happens, it keeps pressure on the brake lines even when you're not slowing down. Solution: Start by cleaning and lubricating the actuator slides. If that doesn't solve it, the entire unit might need to be rebuilt or replaced.

- Reverse Lockout Solenoid Failure (Surge Brakes): If your brakes lock up every time you try to back up the trailer, this is almost certainly the culprit. The reverse lockout solenoid is supposed to block brake fluid from flowing when your tow vehicle's reverse lights come on, but it's not doing its job. Solution: Check the wiring going to the solenoid and make sure your vehicle is sending the reverse signal correctly.

Frequently Asked Questions About Boat Trailer Brakes

Even when you have a good handle on how boat trailer brakes work, a few specific questions always seem to pop up. Let's tackle some of the most common ones we hear from boat owners, clearing things up so you can tow with total confidence.

Can I Add Brakes to an Existing Trailer?

Absolutely. You can definitely retrofit brakes onto a trailer that didn't originally have them. Most trailer axles are built with a "brake flange" already welded on, which makes bolting on a drum or disc brake assembly a pretty straightforward job. But hold on, it's more than just a simple bolt-on project.

You're looking at installing the whole system, which means you'll need:

- Brake assemblies for each wheel you want to brake.

- Hydraulic lines and all the necessary fittings.

- A surge actuator at the tongue or an electric-over-hydraulic (EOH) unit.

- If you go with an EOH setup, you’ll also need to mount a controller in your truck's cab and run the wiring back to the trailer.

While plenty of mechanically savvy boaters take this on as a DIY project, we strongly recommend having a professional handle the installation. This ensures everything is hooked up and calibrated perfectly for maximum safety on the road.

People often think adding brakes is just about staying legal. The reality is, it's a massive upgrade to your stopping distance and overall control, taking a huge load off your tow vehicle's brakes and making every single trip safer.

Do I Need Brakes on Both Axles?

Now this is a critical safety question. For any trailer with tandem axles, the answer really comes down to your total weight (GVWR). While some lighter tandem setups might get away legally with brakes on just one axle, it is always, always safer to have them on both.

Think about it this way: putting brakes on both axles spreads the stopping force evenly across all four tires. This simple step prevents the un-braked axle from trying to push the front one during a hard stop, a sketchy situation that can make the trailer unstable or even cause it to jackknife in an emergency.

For any boat trailer tipping the scales over 5,000 lbs, brakes on both axles shouldn't even be a question—consider it non-negotiable for safe, controlled braking.

At Better Boat, we know that a great day on the water starts with a safe trip to the ramp. We're dedicated to providing top-quality anchoring and trailering equipment to keep your pride and joy secure, both on the highway and at the dock. Check out our full lineup of marine products at https://www.betterboat.com.