Top Boat Trailer Winches: Choose, Install & Maintain

Think of your boat trailer winch as the most reliable crew member you’ve got—the one who does all the heavy lifting, every single time, without a single complaint. It’s way more than just a crank and a strap. It's the essential piece of gear that turns the often-dreaded task of loading a heavy boat into a safe, controlled, and almost effortless process.

The whole point of a boat trailer winch is to give you a massive mechanical advantage. It lets you guide your vessel smoothly onto its trailer with precision, saving you from wrestling with a multi-ton boat at a slippery ramp.

This controlled pull is a world away from risky shortcuts like "power-loading," where you use the boat's engine to force it onto the trailer. Power-loading can scour the ramp with prop wash, gouge your hull on the trailer bunks, and easily lead to a dangerous misalignment. A good winch makes all those risks simply disappear, turning a potentially chaotic moment into a predictable, step-by-step procedure.

The Cornerstone of Smart Boating

At the end of the day, using a winch is just smart, safe boating. It protects your boat, your trailer, and even you from injury. It’s a small investment that pays huge dividends in safety and peace of mind every time you head to the water, especially if you ever need to launch or retrieve your boat by yourself.

The importance of this tool isn't just an opinion; it's reflected across the entire marine industry. The global winch market, which includes everything from massive maritime operations to the trailer winch on your rig, was valued at around USD 2.1 billion in 2024. Experts project it will climb to nearly USD 3.7 billion by 2037, showing just how much we rely on this tech for safe loading and towing. You can dig into more data on the global winch market to see the trends for yourself.

A proper boat winch isn't just a convenience; it's a safety system. It's the critical link that prevents costly accidents and makes boating more accessible and enjoyable for everyone, regardless of physical strength.

Choosing the right winch comes down to understanding the two main types and figuring out which one fits your boat and your needs. Let's break them down.

- Manual Winches: These are powered by good old-fashioned elbow grease. You turn a hand crank, and a gear system multiplies your strength to pull the boat. They are simple, incredibly reliable, and easy on the wallet, making them a perfect match for smaller, lighter boats.

- Electric Winches: These use a 12-volt motor, powered by your tow vehicle’s battery, to do all the work with the push of a button. For bigger, heavier boats, they're a game-changer, offering effortless loading that saves your back and gets you off the ramp faster.

Winch Types at a Glance

To make the choice even clearer, here’s a quick side-by-side look at how manual and electric winches stack up. This should help you zero in on the best option for your setup.

| Feature | Manual Winch | Electric Winch |

|---|---|---|

| Power Source | Human (hand crank) | 12V DC (vehicle battery) |

| Best For | Smaller boats (under 2,500 lbs) | Larger, heavier boats (over 2,500 lbs) |

| Cost | Lower initial cost | Higher initial cost |

| Speed | Slower, dependent on cranking speed | Faster and consistent |

| Effort | Requires physical effort | Effortless, push-button operation |

| Reliability | Very high; few moving parts to fail | High, but relies on motor and electrical connections |

| Installation | Simpler, no wiring required | More complex, requires wiring to the vehicle battery |

| Maintenance | Minimal; occasional lubrication | Requires checking wiring, connections, and motor |

Ultimately, both types get the job done. Manual winches are fantastic for their simplicity and rock-solid reliability, while electric winches offer undeniable convenience for heavier loads. Understanding these fundamental differences is the first step to picking the perfect winch for your boat.

How Your Trailer Winch Creates Pulling Power

Ever stood at the boat ramp and wondered how that little hand crank or a small motor can possibly haul a multi-ton boat up an incline? It’s not magic. It’s a brilliant bit of engineering that uses mechanical advantage to turn a little bit of effort into a whole lot of pulling power.

Ever stood at the boat ramp and wondered how that little hand crank or a small motor can possibly haul a multi-ton boat up an incline? It’s not magic. It’s a brilliant bit of engineering that uses mechanical advantage to turn a little bit of effort into a whole lot of pulling power.

At its core, a boat trailer winch is a force multiplier. It takes your input—whether that’s you cranking a handle or an electric motor whirring away—and uses a simple set of parts to generate the heavy-duty torque needed to get your boat onto the trailer.

The Core Components Working Together

Think of your winch as a small, efficient team where every part has a critical role. For the winch to do its job, every piece has to work in perfect sync. The main players are the handle or motor, the gearbox, the drum, and the strap or cable.

-

The Input Source: This is where it all begins. On a manual winch, it's the handle you’re turning. On an electric winch, it’s the 12-volt DC motor that draws power from your battery.

-

The Gearbox: This is the heart of the operation, where the real power multiplication happens. Inside, a series of gears of different sizes work together to increase torque.

-

The Drum (or Spool): This is the cylinder that your winch strap or cable wraps around. As the drum slowly turns, it winds in the strap, pulling your boat steadily forward.

-

The Strap or Cable: This is your direct link to the boat, connecting the winch to your boat's bow eye. Its strength is just as crucial as the winch's pulling capacity.

These parts work in a beautiful sequence, turning a small action into a powerful result. When you turn that handle or hit the button, you're kicking off a chain reaction of mechanical force.

The Magic of the Gear Ratio

The real secret sauce behind a winch’s muscle is its gear ratio. If you’ve ever ridden a multi-speed bicycle, you already understand the concept. When you shift to an easy gear to pedal up a steep hill, you have to pedal more, but each push is a lot easier. You're trading speed for power.

A winch does the exact same thing. A common gear ratio like 5:1 means you have to turn the handle a full five times just to get the drum to make a single rotation.

This trade-off is the essence of mechanical advantage. By turning the handle five times, your effort is multiplied by five, giving you the power to move something you could never budge on your own. For electric winches, the motor spins very fast with low force, and the gearbox converts that speed into the slow, powerful rotation needed to pull the boat.

This is why a steady crank or a small motor can patiently pull thousands of pounds of boat against gravity and friction. The winch isn't creating energy out of thin air; it's just cleverly converting it, swapping speed for the raw, controlled pulling power you need at the ramp.

Choosing Your Ideal Winch: Manual vs. Electric

Deciding between a manual and an electric winch isn't about finding the "best" one overall—it's about finding the best one for you. This choice really comes down to your specific boat, your own physical abilities, and how you want to spend your time at the boat ramp. It’s a practical decision that has a real impact on how easy and quick every launch and retrieval will be.

Think about two completely different boaters for a second. First, you have a solo operator with a 24-foot cabin cruiser that tips the scales at well over 5,000 pounds. For them, trying to muscle a heavy boat onto the trailer after a long day on the water is a huge chore. An electric winch isn't just a nice-to-have; it's what makes boating possible and keeps it fun.

Now, picture a weekend fisherman with a light and zippy 14-foot jon boat. Their boat is so lightweight it's a breeze to handle. A simple, dependable manual winch is all they need to get the job done quickly and without any drama. It's cheap, needs no wiring, and has almost nothing that can break down.

The Manual Winch: An Honest Day's Work

A manual winch is the very definition of reliable. With fewer moving parts, there’s just less that can go wrong. You're the power source, so you never have to stress about a dead battery or a corroded wire leaving you high and dry at the ramp. That simplicity is its biggest selling point.

They’re also much easier on the wallet upfront, which makes them a great pick for boaters on a budget or those with smaller boats where a powerful electric motor would be serious overkill. The trade-off, of course, is the elbow grease. While the gear ratios do the heavy lifting, you're still the one turning the crank, bit by bit.

The real appeal of a manual winch is its rugged simplicity. It's a trusty tool that just works, every single time, powered by nothing more than your own effort. This makes it a perfect match for smaller boats and for boaters who just want straightforward, fail-proof gear.

The Electric Winch: Power at Your Fingertips

An electric winch turns the physical labor of loading your boat into a simple push-button job. If you have a large, heavy boat, any physical limitations, or you just want to get off the ramp as fast as possible, it's the clear winner. The steady, effortless pull makes retrieving a heavy boat in windy or strong current conditions a much calmer experience.

All that convenience comes with a higher price tag and a more involved installation, since it has to be wired into your vehicle's 12-volt battery. You're also adding more complexity—motors, switches, and wiring all need a look-over now and then to make sure they're in good shape.

For many boaters, though, the time and physical strain saved are well worth the investment. For a rundown of great options, you can check out our guide on boat trailer winch models that suit different needs.

This shift toward user-friendly gear is a big trend in the marine world. A related market, sailboat winches, was valued at around USD 1.2 billion in 2024 and is set to grow, driven by designs that make handling easier for everyone. This shows a wider demand for powered equipment that simplifies the boating experience. You can discover more insights about this growing market and its effect on marine hardware design.

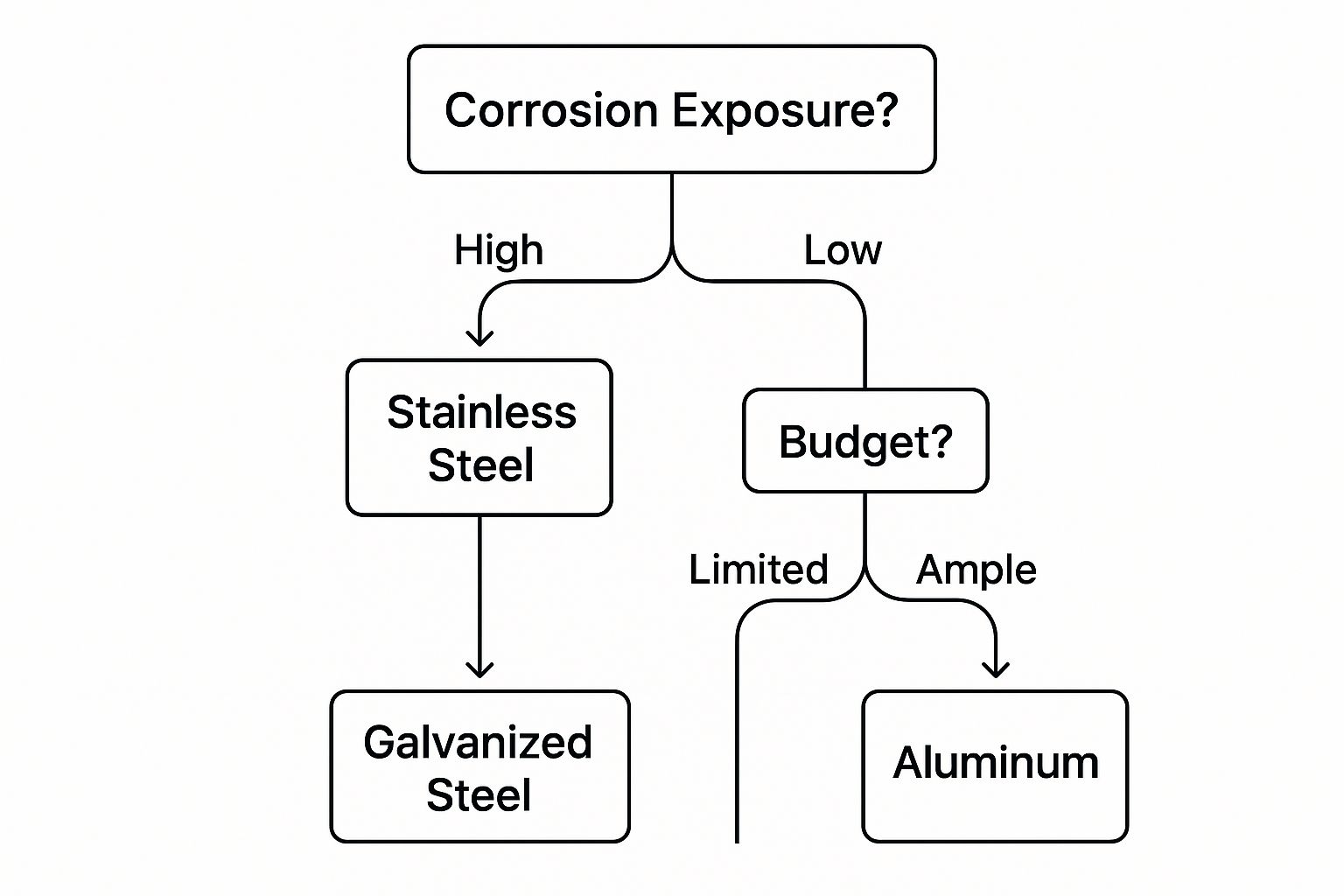

The decision between manual and electric is the biggest one, but it's not the only one. The image below illustrates another key choice you'll face: the material of your winch and its components.

As you can see, your choice between corrosion-resistant materials like stainless steel and more budget-friendly options like galvanized steel really depends on your boating environment and how much you're looking to spend.

Manual vs. Electric Winch Decision Matrix

To help you weigh the pros and cons for your specific situation, we've put together this quick comparison table. Think of it as a cheat sheet to guide you to the right choice.

| Consideration | Manual Winch | Electric Winch |

|---|---|---|

| Boat Size/Weight | Best for smaller, lighter boats (under 3,000 lbs) | Ideal for larger, heavier boats (over 3,000 lbs) |

| Upfront Cost | Lower | Higher |

| Installation | Simple; bolt-on | More complex; requires wiring to a 12V power source |

| Physical Effort | Requires manual cranking | Push-button operation; minimal effort |

| Reliability | Very high; fewer failure points | Good, but relies on battery, motor, and wiring |

| Loading Speed | Slower; depends on user's cranking speed | Faster and more consistent |

| Best For | Budget-conscious boaters, small boats, DIYers | Solo boaters, large boats, users with physical limits |

Ultimately, whether you choose the simple reliability of a manual winch or the effortless convenience of an electric one, the goal is the same: to make your time at the ramp as smooth and stress-free as possible.

How to Correctly Size Your Boat Trailer Winch

Picking the right size for your boat trailer winch isn't just a small technical detail—it's probably the most critical safety call you'll make in this whole process. A lot of folks make a dangerous assumption: they just match the winch capacity to their boat's "dry weight." This is a huge mistake. It completely ignores all the real-world forces you’re up against and can lead to total failure.

Picking the right size for your boat trailer winch isn't just a small technical detail—it's probably the most critical safety call you'll make in this whole process. A lot of folks make a dangerous assumption: they just match the winch capacity to their boat's "dry weight." This is a huge mistake. It completely ignores all the real-world forces you’re up against and can lead to total failure.

When a winch is too small for the job, you're putting a ton of strain on every single part, from the internal gears to the strap in your hand. This skyrockets the risk of the winch giving out or the strap snapping. If that happens, you could be looking at serious damage to your boat or, even worse, a severe injury to anyone standing nearby. To get this right, you have to figure out the total weight your winch will actually be pulling up that ramp.

Calculating Your True Working Load

To land on the right capacity, you need to think way beyond the boat's empty weight. The number you're really after includes everything the winch has to haul up that incline. It's a lot like calculating Gross Trailer Weight (GTW) for trailering, and the same logic holds true here.

Here's a simple way to figure out your total load:

Boat Weight + Engine Weight + Fuel/Water Weight + Gear Weight = Total Loaded Weight

Let’s quickly break that down:

- Boat Weight: This is the "dry weight" listed by the manufacturer. It's your starting point.

- Engine Weight: Don't forget about your outboard or inboard motor. They can easily add hundreds of pounds.

- Fuel and Water: A full tank of gas and any onboard water tanks add up fast. A gallon of gas is about 6 pounds, and water is over 8 pounds per gallon.

- Gear Weight: Think about everything else—from anchors and safety gear to coolers and fishing tackle. If you want to dive deeper into how heavy some gear can be, check out our guide on choosing the right anchors for boats.

Once you have this Total Loaded Weight, you're ready to make a smart choice.

Applying the Critical Safety Factor

Okay, you've calculated your total loaded weight, but you can't stop there. Now you have to add a serious safety margin. This accounts for the friction of dragging the hull over the trailer bunks and the steepness of the boat ramp. Your boat isn't just being lifted; it's being pulled up a slope against resistance.

Safety Rule of Thumb: Your winch capacity should be at least 1.5 to 2 times your Total Loaded Weight.

Let's say your fully loaded boat tips the scales at 3,000 pounds. You should be shopping for a winch with a capacity somewhere between 4,500 and 6,000 pounds. Going for the higher end of that range gives you an even bigger buffer, ensuring your winch lasts longer and performs reliably when you need it most. That extra capacity means the winch isn't constantly maxed out, which drastically reduces wear and tear.

This focus on stronger, more reliable materials is a big deal across the industry. The boat trailer market, valued at USD 1.12 billion in 2025, is expected to hit USD 1.70 billion by 2035. A huge part of that growth is the move toward lightweight, corrosion-resistant materials like aluminum that hold up better in harsh saltwater environments. This trend is shaping everything, right down to accessories like winches.

Single Line vs. Double Line Pulling

One last thing to understand is how the winch's capacity is rated. Most winches list their capacity for a "single-line" pull—a straight line from the winch to the boat. Some of the heavy-duty models offer a "double-line" option that uses a pulley block (also called a snatch block). This clever setup basically doubles the winch's pulling power by cutting the pulling speed in half.

While a double-line configuration is great for really heavy boats, you should always size your winch based on its single-line rating. It’s simpler and safer. And remember, your winch system is only as strong as its weakest link, so make sure your winch strap or cable has a break strength that’s higher than the winch’s capacity.

Installing Your New Winch Step by Step

You've done the research and picked out the perfect winch. Now it's time to get it on the trailer. Getting this part right is every bit as important as choosing the right size in the first place. A poorly mounted winch isn't just a hassle—it's a serious safety hazard. But don't worry, by following a few clear steps, you'll have your gear installed securely and ready for action.

Before you even think about touching a bolt, let's talk safety. Park your trailer on solid, level ground and chock the wheels so it can't go anywhere. If you're swapping out an old, tired winch, now's the time to get it off, being careful with any crusty, rusted hardware you encounter.

Preparing the Winch Mount

Your new winch will bolt onto the winch stand (or post) on your trailer's tongue. Give this area a good, hard look. You're searching for any signs of serious rust or damage that could compromise its strength. If the stand is bent, cracked, or rusted through, it absolutely has to be repaired or replaced before you go any further.

Next, line up your new winch with the mounting holes on the stand. Most winches and stands follow a standard bolt pattern, but it's always smart to double-check. Make sure you've got the right hardware—stainless steel bolts, nuts, and washers are your best friends here, as they'll fight off corrosion for years to come.

- Position the Winch: Set the winch right onto the mounting plate.

- Insert Bolts: Drop the mounting bolts down through the holes in the winch and the stand.

- Secure Hardware: From underneath, slide on a flat washer, then a lock washer, and finally a nut for each bolt.

- Tighten Securely: Get all the nuts hand-tight first. Then, using a wrench and socket, tighten them down completely. I like to alternate between the bolts in a crisscross pattern, just like tightening lug nuts on a wheel. This ensures you get nice, even pressure across the base.

A properly torqued bolt is critical. We're not just talking "tight." We're talking torqued to the manufacturer’s specs. This is what keeps the winch from vibrating loose on the highway and shifting under load, which would create a really dangerous situation at the ramp.

Winding the Strap or Cable

With the winch body bolted on solid, your next job is getting the strap or cable spooled onto the drum correctly. If you do this wrong, the strap can slip under load, and that's a recipe for disaster. Start by feeding the looped end of the strap over the mounting bolt on the winch drum and get it secured.

Now, begin slowly winding the winch strap onto the drum. The key here is to make sure it lays perfectly flat and doesn't get twisted. You'll need to keep some tension on the strap with one hand while you crank with the other. Guide it from side to side so it spools evenly across the entire drum, leaving no big gaps. A neatly wound strap prevents jams and ensures a smooth, straight pull when you retrieve your boat.

Connecting an Electric Winch

If you went with an electric model, you've got one more crucial step: the wiring. This is where attention to detail really pays off, ensuring you have a safe and reliable power source. It all comes down to using the right gauge wire and protecting the circuit.

- Run the Wires: Carefully route the positive and negative cables from the winch all the way back to your vehicle's battery. Be smart about it—keep the wires away from sharp metal edges and any moving parts. Using a plastic wire loom is a great way to add extra protection.

- Install a Circuit Breaker: This is non-negotiable. You must install an appropriately rated inline circuit breaker or fuse on the positive wire, as close to the battery as possible. This is what protects the winch motor from a power surge and, more importantly, prevents a fire if you ever get a short circuit.

- Make Secure Connections: Use high-quality ring terminals to connect the wires directly to the battery posts. A loose connection here can cause all sorts of problems, from a frustrating loss of power to dangerous heat buildup.

A solid winch installation is a huge part of your trailering safety. To make sure the rest of your rig is just as ready, check out our guide to boat trailer maintenance tips and guarantee every trip to the water is a safe one.

Winch Maintenance and Troubleshooting Tips

A boat trailer winch that works every single time isn't a matter of luck—it's a sign of good care. Just like any other critical piece of gear on your boat, a little proactive maintenance goes a long way. It's the key to preventing a frustrating, and potentially dangerous, failure at the worst possible moment. Nobody wants to be that guy holding up a busy launch ramp.

A boat trailer winch that works every single time isn't a matter of luck—it's a sign of good care. Just like any other critical piece of gear on your boat, a little proactive maintenance goes a long way. It's the key to preventing a frustrating, and potentially dangerous, failure at the worst possible moment. Nobody wants to be that guy holding up a busy launch ramp.

A simple but consistent routine will dramatically extend the life of your winch and ensure it’s ready to go when you are. Think of it as a quick pre-launch check. Taking a minute to look things over before and after each trip can help you spot small issues before they snowball into big, expensive problems.

Your Regular Maintenance Checklist

Creating a solid inspection routine is easy. You just need to focus on the parts that do the most work and take the most abuse from the elements. This is where wear and tear will always show up first.

- Inspect the Strap or Cable: This is your winch's lifeline. Check the entire length of your winch strap for any signs of fraying, cuts, or UV damage, which often looks like faded or brittle fabric. For steel cables, always wear thick gloves and feel for broken strands or kinks. These are serious safety hazards that mean it's time for a replacement.

- Lubricate Moving Parts: Keep all the gears and bushings moving freely. A light coat of high-quality marine-grade grease on the gears and a bit of oil on the handle shaft prevents binding and cuts down on wear. This is especially important if you're launching in saltwater.

- Check Mounting Bolts: The vibrations from just driving down the road can slowly loosen the bolts holding your winch to the trailer. Give them a quick check with a wrench to make sure they're still snug and secure. A loose winch is a dangerous winch.

A well-maintained winch isn’t just about making life easier; it's a critical safety system. Neglecting basic upkeep on parts like the strap or mounting hardware can lead to catastrophic failure under load, putting your boat and anyone nearby at risk.

If you have an electric winch, you have a couple of extra checks to perform. Always make sure the wiring is free of cracks and that all connections are tight and clean. A dab of dielectric grease on the electrical terminals works wonders to prevent the corrosion that can kill power flow.

Troubleshooting Common Winch Problems

Even with the best maintenance, things can sometimes go wrong. When your winch starts acting up, don't panic. A calm, systematic approach will help you figure out the issue in no time.

Problem 1: The Winch Won't Engage or is Slipping

You’re cranking the handle, but the drum isn’t turning, or worse, it slips backward under load. The problem is almost always with the pawl—that little lever that makes the clicking sound against the gear.

- Check the Pawl Spring: The most common culprit is a weak or broken spring that can't push the pawl firmly into the gear teeth anymore.

- Inspect for Debris: Clean out any sand, grime, or old, hardened grease that might be physically stopping the pawl from engaging properly.

Problem 2: The Electric Winch is Dead

You hit the switch and... nothing. Before you assume the motor is fried, always start with the simplest solutions first.

- Check the Power Source: It sounds obvious, but is your vehicle's battery connected and charged?

- Inspect Connections: Look for loose or corroded battery terminals. A bad connection is a very common reason for power failure.

- Find the Fuse: Check for an inline fuse or a circuit breaker. A blown fuse is a cheap and easy fix that often solves the problem instantly.

Common Questions About Boat Trailer Winches

Even after you get the hang of sizing and installation, a few questions always seem to pop up about using your winch day-to-day. We hear them all the time. Think of this as your quick-reference guide for those practical, on-the-ramp uncertainties.

Getting these details straight is what builds confidence and keeps you from making costly mistakes. We'll cover everything from strap choice to when it's time for a replacement.

Can I Use a Strap Rated Higher Than My Winch?

Yes, and honestly, you should. It's a fantastic safety practice. Using a winch strap with a break strength that’s way higher than your winch's capacity just builds an extra layer of security into your whole setup.

Here’s how to think about it: if you somehow hit an extreme load, the winch gears will just stall out long before the strap is even close to its breaking point. This gives you a predictable, safe point of failure. The opposite, however, is a recipe for disaster. Never use a strap rated lower than your winch. It could easily snap under a heavy pull, and that's a dangerous situation you don't want to be in.

Should I Choose a Winch Strap or a Steel Cable?

For almost every recreational boater out there, a modern synthetic strap is the way to go. The reasons are all about safety and just making your life easier.

- Synthetic Straps: These are typically made of tough polyester webbing. If one ever did break, it loses energy almost instantly and just drops to the ground. They’re also lighter, don't rust, and are a whole lot nicer to your hands and your boat's finish.

- Steel Cables: Sure, they’re tough against abrasion. But they have one massive drawback: if a steel cable snaps under tension, it can whip back with incredible force. This can cause serious injury or damage. They also need to be oiled to fight rust and can develop nasty little broken wires—we call them "fish hooks"—that will tear up your hands.

Unless you're dragging your boat over rocks and gravel every single day, a quality strap is the smarter, safer bet.

The goal here is simple: cut out risk wherever you can. A synthetic strap that fails safely is always a better choice than a steel cable that could turn into a projectile. It’s an easy decision that makes the launch ramp a much safer place.

How Often Should I Replace My Winch Strap?

There isn't a strict "use by" date on a winch strap because its life really depends on how much you use it, how much sun it gets, and how well you take care of it. Forget the calendar—get in the habit of giving it a quick inspection before every single trip.

Keep an eye out for these red flags:

- Fraying or Fuzziness: If the edges are starting to look seriously frayed, the strap’s strength is compromised.

- Cuts or Nicks: Even a small slice can dramatically weaken the strap.

- UV Damage: The sun is brutal on synthetic fibers. If your strap looks faded, feels stiff, or is discolored, it’s been weakened by UV rays and needs to go.

As a solid rule of thumb for preventative maintenance, it's a good idea to replace your strap every 2-3 years, even if it looks okay. It’s a cheap piece of insurance that buys a lot of peace of mind.

Is It Safe to Use My Winch to Hold the Boat While Driving?

No. Absolutely not. This is hands-down one of the most common and dangerous mistakes we see new boaters make. The brake and gear system in a winch—whether it's manual or electric—is only designed to handle the force of pulling a boat onto the trailer.

They are not designed to withstand the dynamic forces of bouncing down the road, hitting the brakes, or accelerating. If you rely only on the winch, it could slip or the gears could fail entirely. That could let the boat slide back or, in a worst-case scenario, come right off the trailer.

Always, always secure your boat for the road with a separate system. This means a heavy-duty safety chain or strap on the bow eye and a pair of strong transom tie-down straps at the stern. The winch gets the boat on the trailer; tie-downs keep it on for the ride.

At Better Boat, we know that reliable trailering gear is key to a stress-free day on the water. From durable winch straps to secure tie-downs, we offer expertly tested equipment to keep your investment safe. Explore our full range of boating and trailering accessories today. Find your perfect solution at https://www.betterboat.com.