Your Essential Dock Line Size Chart

When you're tying up your boat, having the right gear is non-negotiable. A good rule of thumb I've always relied on is to use 1/8 inch of diameter for every 9 feet of boat length. It's a simple calculation that gets you in the right ballpark. For instance, if you have a 27-foot boat, you'll want to start by looking at a 1/2-inch line.

This guideline is your starting point for making sure you’ve got enough strength for secure mooring, especially when conditions are calm.

Your Quick-Reference Dock Line Size Chart

Picking the right dock line is one of the most fundamental parts of safe boating. While your boat's length is a great place to start, it's just one piece of the puzzle you'll need to solve for total peace of mind at the dock.

Using a properly sized line is about more than just keeping your boat from drifting away. It prevents unnecessary strain on your boat's cleats and the dock hardware, which is especially critical during rough weather or when you're dealing with wakes from passing boats. Go too thin, and you risk a line snapping under pressure. But a line that's too thick won't have enough give to absorb shock loads, which can be just as damaging.

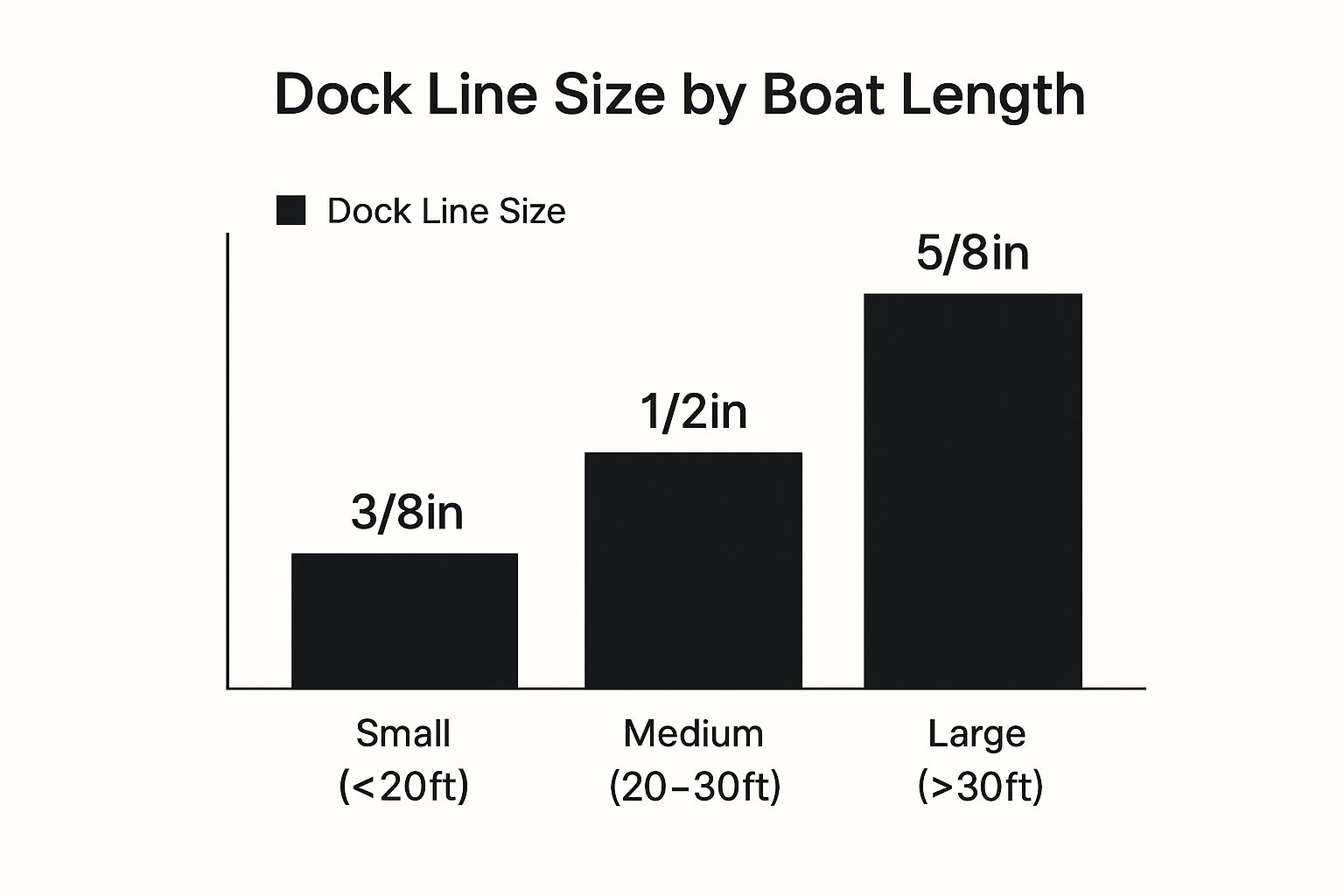

This chart is a fantastic visual guide that shows the general relationship between boat length and the recommended rope diameter.

As you can see, the line diameter needs to increase to handle the bigger forces that come with longer, heavier boats. It's a principle that's recognized by boaters all over the world. The chart below gives you a more detailed breakdown based on that common rule of thumb.

Recommended Dock Line Diameter By Boat Length

Here's a quick lookup table that makes it easy to find the minimum dock line diameter you should be using based on your boat's overall length.

| Boat Length (Feet) | Recommended Line Diameter (Inches) | Recommended Line Diameter (mm) |

|---|---|---|

| Up to 27' | 3/8" | 9.5 mm |

| 28' - 31' | 1/2" | 12.7 mm |

| 32' - 36' | 5/8" | 15.9 mm |

| 37' - 45' | 3/4" | 19.1 mm |

| 46' - 54' | 7/8" | 22.2 mm |

| 55' - 63' | 1" | 25.4 mm |

Remember, this chart is your first step toward confident, secure docking. You can always learn more about mooring best practices from seasoned experts. But having this reference on hand is the best way to ensure you're starting with the right equipment for the job.

Why Boat Displacement Often Matters More Than Length

Sure, a boat's length is an easy number to grab when you're trying to pick out dock lines, but it's the boat's total weight—its displacement—that tells the real story. Imagine trying to stop a runaway pickup truck versus a small sports car. Even if they're the same length, one carries a whole lot more force, and it's the exact same principle with your boat.

A heavier vessel has more momentum and catches more wind and current, which puts way more strain on your dock lines. This is where those simple length-only charts can lead you astray. You could have two 35-foot boats side-by-side, but if one is a nimble center console and the other is a heavy-displacement trawler, their needs are worlds apart.

Calculating The True Load

The key to understanding the real-world load your lines will face is your boat’s displacement, which is simply its weight in the water. You can almost always find this number tucked away in the owner's manual or on the manufacturer's spec sheet.

Pro Tip: Don't forget to factor in all the "stuff" you've loaded onto the boat. The listed "dry weight" doesn't account for fuel, water, gear, and supplies. A fully loaded cruiser can easily weigh thousands of pounds more, and that extra weight directly translates to extra stress on your lines.

This is exactly why good recommendations always consider both length and displacement. Dock line sizing is critical; for instance, a 34-foot boat that displaces 12,000 pounds really ought to have a 19 mm (3/4 inch) diameter line. Relying on length alone might suggest a smaller 16 mm (5/8 inch) line, which just wouldn't have the same muscle. For a deeper dive into how weight changes the game, check out the detailed examples in the 2025 ultimate dock line size guide.

If you find your boat's weight puts it right on the edge between two line sizes, always size up. That extra strength isn't just for show; it's your safety margin against a surprise squall or a large wake from a passing vessel, ensuring your boat stays put right where you left it.

Choosing the Right Dock Line Material

Once you’ve nailed down the right diameter using a dock line size chart, picking the right material is your next big decision. This choice is critical. The best material will handle the constant tug-of-war from wind and waves while standing up to the harsh sun and salt of the marine world.

The big three you'll encounter are nylon, polyester, and polypropylene. Each one has its own set of strengths and weaknesses, making them suited for different jobs.

Nylon: The King of Stretch and Strength

For most boaters, nylon is the go-to choice for dock lines, and for good reason. It’s incredibly strong, but its real superpower is elasticity. This built-in stretch acts like a shock absorber for your boat, soaking up the sudden jolts from passing boat wakes or strong wind gusts.

Think of it as a heavy-duty bungee cord. That stretch protects your boat's cleats from the jarring forces that can weaken and damage hardware over time. It does have one small catch: nylon loses about 10-15% of its strength when it gets wet. Don't worry, this is already accounted for in its rated breaking strength, but it's good knowledge to have.

Polyester: The Durable, Low-Stretch Workhorse

Polyester is another fantastic option, but it plays a different role. It’s known for its high strength, very low stretch, and amazing resistance to UV rays and abrasion. Unlike nylon, polyester keeps its full strength even when soaking wet.

This makes it an unbeatable choice for permanent or semi-permanent mooring, where lines are exposed to the elements 24/7. Because it doesn't stretch much, it's not the best for absorbing shock, but it’s perfect for spring lines where your goal is to keep the boat from moving around too much.

Polypropylene: The Lightweight Floater

Then there’s polypropylene. It’s cheap, very lightweight, and it floats, which can be handy. But that's where the advantages mostly end. It’s much weaker than nylon or polyester and breaks down quickly from sun exposure and chafing.

Frankly, it's not a material I'd trust for primary dock lines on anything bigger than a small dinghy or kayak. For anything with significant weight or value, you'll want to stick with nylon or polyester.

Dock Line Material Comparison

With so many factors at play, a side-by-side comparison can really help clear things up. This table breaks down the most important characteristics of the three main dock line materials so you can see at a glance which one fits your needs.

| Material | Strength | Stretch (Shock Absorption) | UV Resistance | Abrasion Resistance | Best Use Case |

|---|---|---|---|---|---|

| Nylon | Excellent | Excellent | Good | Good | All-purpose dock lines, especially bow and stern lines for shock absorption. |

| Polyester | Excellent | Poor | Excellent | Excellent | Permanent mooring, spring lines, or any application needing minimal stretch. |

| Polypropylene | Poor | Poor | Poor | Poor | Small dinghies, kayaks, or as a temporary "heaving" line to pass a heavier line. |

Ultimately, picking the right material comes down to the job at hand. For most recreational boaters tying up for the day or a weekend, you simply can't go wrong with high-quality three-strand or double-braid nylon. It delivers the best all-around package of strength, shock absorption, and durability for everyday docking.

Determining the Proper Dock Line Length

While picking the right diameter for your dock lines is crucial, getting the length right is just as vital for keeping your boat secure and giving you options at the dock. If your lines are too short, you'll find your docking choices severely limited, and they can get dangerously tight with changing tides. On the flip side, lines that are way too long just become a tangled mess on deck, creating a serious trip hazard and making them a pain to handle.

Finding that sweet spot means you're ready for just about any docking situation, whether it's your familiar home slip or a new transient dock. The real key is to have lines specifically sized for their jobs.

Standard Line Lengths Explained

Different lines on your boat do different things, so it only makes sense that they need to be different lengths. By following a few proven rules of thumb, you can outfit your boat without any guesswork, giving you confidence when you need it most. Think of these as guidelines for maximum adaptability.

- Bow and Stern Lines: These are your main workhorses. They should be about two-thirds (2/3) of your boat's total length. So, for a 30-foot boat, you're looking at lines around 20 feet long. This is plenty for most standard tie-ups without being overly clumsy.

- Spring Lines: These are the unsung heroes that stop your boat from surging forward or backward. Your spring lines should be equal to your boat's full length. That same 30-foot boat needs 30-foot spring lines to give you the flexibility to reach different cleats and maintain total control.

A classic mistake is grabbing one of those pre-packaged sets where all the lines are the same short length. This almost always leaves you without enough rope for proper spring lines, which are arguably the most critical for stability, especially if you're staying a while or dealing with current.

Having the right line lengths for each task is a cornerstone of good seamanship. For a deeper dive, you can learn more about the different types of dock lines and their uses. When you stick to these length guidelines, you're making sure your boat is not just secure, but also ready for whatever the wind and tides throw at it, keeping your investment safe and sound.

Understanding Tensile Strength vs Safe Working Load

When you're looking at rope specs for your dock line size chart, two numbers will always jump out: tensile strength and safe working load (SWL). It's absolutely crucial to know the difference, because only one of them actually matters for keeping your boat tied up safely.

Tensile strength is the big, impressive number. It’s the absolute maximum force a brand-new rope can take in a controlled lab setting right before it snaps. While it looks good on paper, it's not a realistic measure for day-to-day use on the water.

The Real-World Metric: Safe Working Load

This is where safe working load (SWL) comes into play, and it’s the number you should always be looking at. SWL is a much more conservative rating, usually calculated as a small fraction—just 15-25%—of the tensile strength. This is the figure to use when you're making decisions.

So, why the huge gap between the two? Because in the real world, several things constantly work to weaken your lines:

- Knots: Tying even a simple knot can slash a line's strength by up to 50%.

- Age and UV Exposure: The sun is relentless. Over time, its rays make rope fibers brittle and weak.

- Chafe: That constant rubbing against cleats, chocks, or rough pilings slowly saws through the rope.

- Shock Loads: A sudden jolt from a passing boat's wake or a gust of wind puts a massive, brief strain on the line that far exceeds the steady load.

Choosing a thicker line from the size chart gives you a higher SWL and, more importantly, a much-needed safety buffer. This is just as critical as choosing the right anchor; our guide on choosing the right anchor styles, weights, and materials can walk you through that equally vital part of securing your boat. Always, always prioritize a high SWL to protect against the unexpected and ensure your boat stays put.

Essential Dock Line Questions Answered

Even with a perfect dock line size chart, you're going to have questions once you're actually out on the water. It's just the nature of boating. How many lines do I really need? When should I start doubling them up? Getting these common questions sorted will make you a more confident skipper and keep your boat right where you left it.

Think of your dock lines as your boat's safety net. Choosing the right diameter is just one piece of the puzzle. Knowing how many to have on hand and how to use them in different situations is just as crucial. Let's dig into some of the most common questions we hear from fellow boaters.

How Many Dock Lines Should I Carry?

For most day-to-day docking, the standard advice is to have a minimum of four lines. This setup usually means two bow/stern lines and two spring lines, which gives you a solid, secure tie-up in a typical slip.

But experienced boaters know that "minimum" is rarely enough. It's always a smart move to carry extra lines. You just never know when you'll pull into a transient dock with poorly placed cleats or need to add an extra line for security during a squall.

As a rule of thumb, it's far better to have more lines than you need than to need an extra line you don't have. Four is the absolute minimum, but carrying six to seven lines on board gives you real-world versatility.

When Should I Double My Dock Lines?

Doubling up—that is, using two separate lines on a single cleat or piling—is all about adding redundancy and peace of mind. It's a non-negotiable practice in a few key situations.

You should always double your lines when:

- A storm is on the way: The forces from high winds and surging waves can put incredible strain on your gear.

- You're leaving the boat unattended for a while: This gives you a backup in case one line chafes through or gives way.

- You're moored in a spot with heavy boat traffic or big tides: Constant wakes and changing water levels demand extra security.

This simple practice means that if one line fails, a second one is already there, holding your boat securely. It's especially critical for overnight stays; knowing your boat is safe is key to a good night's sleep. For those of you living aboard, you might also find our guide on how to sleep comfortably while living aboard helpful.

Is It Okay To Use Different Size Lines?

While using lines of all the same size is ideal, it’s not always practical. For your primary working lines—the bow, stern, and spring lines—you should absolutely stick to the size recommended for your boat's displacement on a reliable dock line chart.

Using a line that's a size up is perfectly fine and just adds an extra margin of safety. However, you should never use an undersized line for a primary mooring job. Doing so introduces a dangerous weak link in your setup. It might be okay to use a smaller, older line for something temporary like hoisting a fender, but your main lines must be up to the task.