A DIY Guide to Epoxy Resin for Boat Repair

Let's get straight to it: when it comes to boat repairs, professionals and seasoned DIYers alike turn to epoxy resin for boat repair. Why? Because it delivers incredible strength and creates a bulletproof waterproof barrier. It’s not just a patch; it forms a chemical bond that can be even stronger than the original material, giving you a permanent, structural fix.

Why Pros Trust Epoxy for Marine Repairs

When your boat is out on the water, there’s simply no room for compromise. The integrity of your vessel is everything, whether you're dealing with small nicks and gouges or more serious structural problems like delamination. This is precisely where marine-grade epoxy proves its worth, cementing its reputation as the gold standard in the boating world.

This isn’t just talk; it's chemistry. Unlike older polyester resins that can become brittle and shrink over time, epoxy creates a bond that is both incredibly strong and surprisingly flexible. That flexibility is a huge deal for modern boat hulls, which are engineered to flex and move under the stress of waves and motion.

The Unbeatable Combo of Adhesion and Water Resistance

One of the biggest reasons experts swear by epoxy resin for boat repair is its phenomenal adhesion. It doesn't just sit on top of a surface—it becomes one with it through a powerful chemical bond. This works wonders on all the common materials you find on a boat:

- Fiberglass: Epoxy creates a seamless, incredibly strong bond with fiberglass laminates, which is non-negotiable for hull repairs.

- Wood: It soaks deep into wood fibers, completely sealing them from moisture to prevent rot while reinforcing the wood's natural structure.

- Aluminum and Metals: After a bit of surface prep, epoxy clings tightly to metals, making it perfect for all sorts of fixes on board.

This powerful grip also creates an unmatched moisture barrier. Water is the relentless enemy of any vessel, and epoxy’s low porosity effectively shuts the door on water intrusion, preventing nasty osmosis blisters and other water-related headaches.

A lot of people make the mistake of thinking a repair is just about filling a hole. A proper epoxy repair actually becomes a new, integral part of the boat's structure, restoring—and often improving—its original strength.

Epoxy Resin vs Other Adhesives for Boat Repair

It's easy to get overwhelmed by the different adhesives on the shelf. To clear things up, here’s a quick look at how marine epoxy stacks up against other common options you might see.

| Attribute | Marine Epoxy Resin | Polyester Resin | Polyurethane Sealant |

|---|---|---|---|

| Strength | Superior structural strength | Good, but more brittle | Flexible, not structural |

| Adhesion | Excellent to most materials | Good for fiberglass, poor on wood | Good, but for sealing, not bonding |

| Waterproof | Excellent, very low porosity | Prone to water absorption/osmosis | Excellent for sealing joints |

| Flexibility | Good, handles hull flex | Brittle, can crack under stress | Very flexible |

| Shrinkage | Very low to negligible | Moderate, can pull away from edges | Low shrinkage |

| Best For | Structural repairs, bonding, coating | Fiberglass patching, mold making | Sealing gaps, bedding hardware |

| Cost | Higher initial cost | Lower cost | Moderate cost |

As you can see, while other products have their place, nothing beats the all-around performance of marine epoxy for repairs that need to be strong, durable, and completely waterproof.

A Proven Choice in a Demanding Industry

The move toward epoxy in high-performance marine applications isn't a secret. The marine composites industry, especially builders of racing yachts and other high-stress vessels, almost exclusively uses epoxy for its sheer mechanical superiority and chemical resistance.

Ultimately, using the right materials is a mark of professionalism. It’s about understanding the science behind the repair, much like how professional scuba repairs are critical for diver safety. Choosing the right epoxy isn’t just about fixing a crack; it’s an investment in your boat’s future safety and longevity, ensuring every repair is truly built to last.

Choosing the Right Epoxy for Your Project

Stepping into the world of marine epoxy can feel like a lot, with shelves full of different systems all promising the best results. I've learned over the years that the secret isn't finding one "magic" epoxy, but picking the right system for the specific repair you're tackling. Getting this choice right from the start saves you time, money, and the absolute headache of a failed bond down the road.

The whole decision really boils down to two key things: the epoxy's viscosity (how thick or thin it is) and the hardener's cure speed. These aren't just technical specs; they directly impact how the epoxy resin for boat repair will behave and perform on your vessel.

Viscosity: Your Key to Strength and Saturation

Viscosity is all about how the epoxy flows and soaks into a surface. It’s a critical choice that depends entirely on the job you've got in front of you.

-

Low-Viscosity Epoxies: These are thin, runny, and flow like warm honey. Their biggest strength is saturation. They’re perfect for "wetting out" fiberglass cloth, making sure every last fiber is fully encapsulated. They’re also what you want for seeping into porous wood to seal it or getting deep into tight cracks for a solid, structural bond.

-

High-Viscosity Epoxies: Think thick, paste-like systems. Some even come pre-thickened with fillers. Their main job is to fill gaps without sagging or running all over the place. I grab these for any vertical or overhead repairs, creating strong structural fillets, or filling big gouges where a thinner epoxy would just drip out.

For a really deep dive, check out our ultimate guide to choosing epoxy resin for your boat, which breaks these properties down even further. If you start thinking about your project in terms of "saturation vs. gap-filling," you'll narrow down your options in no time.

Hardeners: Controlling Your Working Time

The hardener you pick controls your "pot life"—the amount of time you have from the moment you mix the resin and hardener until it starts to gel and becomes unworkable. Picking between a fast or slow hardener isn't about speed; it's about strategy.

A classic rookie mistake is thinking faster is always better. Trust me, rushing a job with a fast hardener on a warm day can lead to the epoxy kicking off in the mixing pot before you even get it applied properly.

A fast hardener is great for small, quick fixes in cooler weather, say around 50-70°F. It lets you get the job done and move on without a long, frustrating wait. But using that same hardener on a hot day or for a big lamination job is just asking for trouble.

On the other hand, a slow hardener is your best friend for larger projects or anytime you're working in warm climates (above 75°F). It gives you plenty of time to mix, apply, and smooth out the epoxy without that frantic, rushed feeling. This extra working time is absolutely crucial for getting a smooth, bubble-free finish on big jobs, like re-laminating a section of the hull.

Prepping Your Boat for an Unbreakable Bond

Even the best epoxy resin for boat repair is going to fail if you don't prep the surface correctly. It’s a hard lesson many boaters learn the expensive way. The reality is, a staggering 90% of epoxy adhesion failures come from bad prep work, not a bad batch of resin. A solid, permanent repair is only as good as its foundation.

Think about it this way: epoxy needs something to physically bite into. If the surface is smooth, dirty, or has any wax on it, the epoxy has nothing to grab. Your job is to create a clean, dry, and perfectly textured profile that lets the resin lock into the substrate and form a truly mechanical bond.

The Critical Cleaning Phase

Before you even dream of picking up a sander, you have to get every last bit of surface contamination off. Adhesion killers like wax, oil, grease, and silicone are your worst enemies, and you often can't even see them. Wiping the area down with a good solvent isn't just a suggestion—it's the mandatory first step.

Grab a clean, lint-free rag and dampen it with a solvent like denatured alcohol or acetone. I always use the "two-rag method" for this. Wipe the area with the wet rag in one direction, then immediately come back with a clean, dry rag to lift the contaminants off before the solvent flashes off. If you skip the dry rag, you're just smearing the gunk around.

For those extra greasy spots, especially near the engine or in the bilge, you might need something more heavy-duty. To make sure you leave no residue behind, you can learn more about effective boat bilge cleaning and degreasing techniques.

Creating the Mechanical Key

Once it's completely clean, it's time to give that epoxy a surface it can really sink its teeth into. For any repair that needs to be structurally sound, you have to grind away all the weak, damaged, or delaminated material. Use a high-speed grinder or a sander with some aggressive paper—think 36 or 60-grit—to get down to fresh, solid laminate.

As you grind out the bad stuff, you'll want to "feather" the edges. This just means creating a gradual slope from the healthy surface down into the deepest part of the repair. A great rule of thumb is a 12:1 ratio. So, for every 1/8 inch of depth, you need to create a beveled edge of at least 1.5 inches. This gentle taper spreads out the stress and prevents a hard edge where the patch could fail.

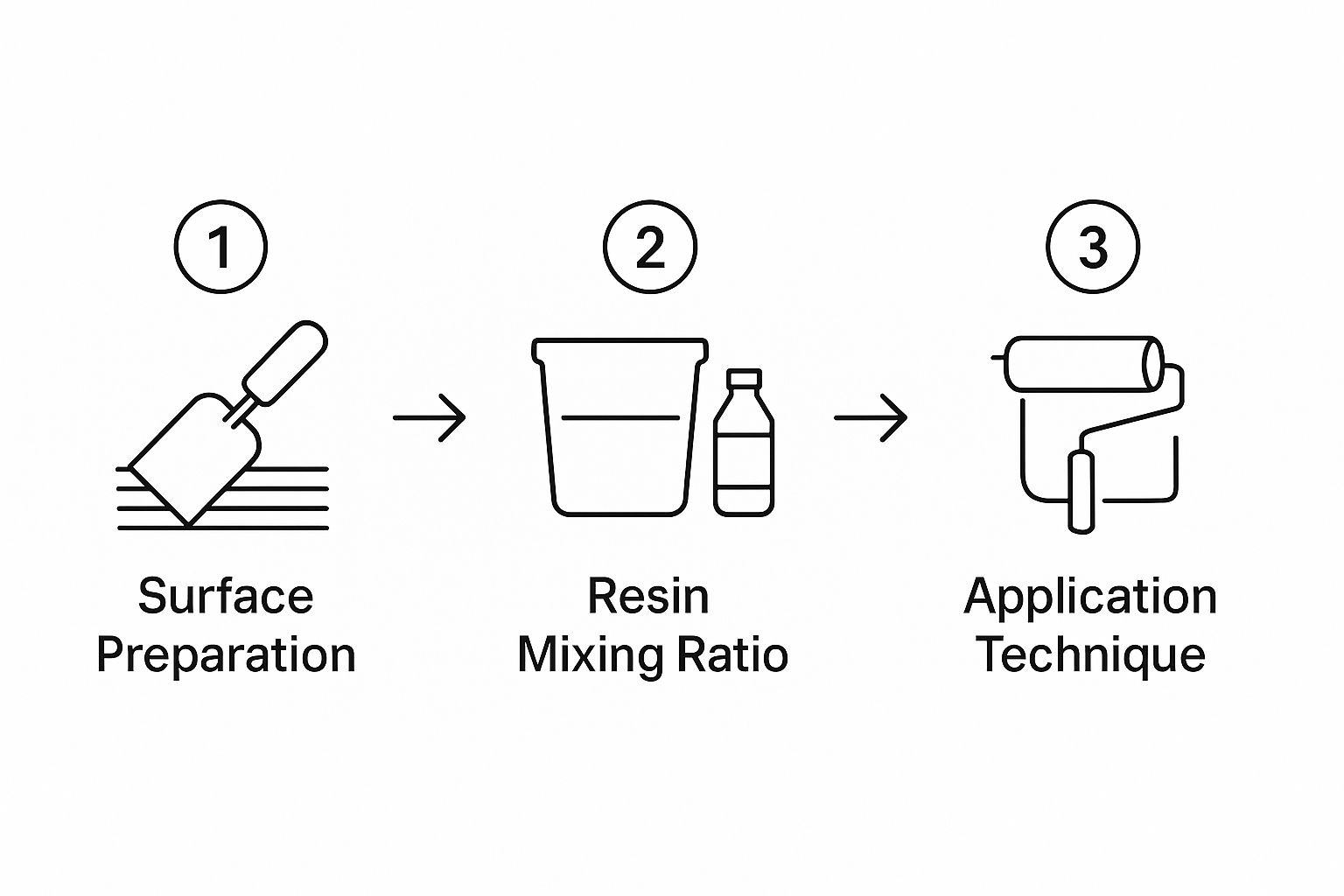

This image really drives home the workflow, from the first wipe-down to the final application.

It highlights how each step builds on the one before it. If you rush or skip the prep, you're directly weakening the final bond. It’s that simple.

The most common mistake I see is boaters trying to fill a deep gouge without properly beveling the edges. This creates a weak 'plug' that can easily pop out under stress, instead of an integrated repair that becomes one with the hull.

Ensuring a Bone-Dry Surface

This last step is absolutely critical: moisture control. During the application and curing stages, epoxy and water are mortal enemies. Slapping resin onto a damp surface will give you a cloudy, weak bond that is practically guaranteed to fail.

The surface must be totally, completely, bone-dry. If you just washed the boat or it got caught in the rain, let it air dry for plenty of time. If you want to be extra sure, you can gently warm the repair area with a heat gun or even a hairdryer. Just be careful not to blast it with too much heat and damage the substrate. Getting rid of every last drop of moisture is your final checkpoint before you can confidently start mixing your epoxy.

Mixing and Applying Epoxy Like an Expert

This is where the magic happens. All your careful prep work comes down to this moment, where good craftsmanship meets a bit of chemistry. Mixing and applying epoxy resin for boat repair isn't rocket science, but it absolutely demands precision. Nail this part, and you'll be rewarded with a repair that’s not just strong, but seamlessly integrated into your boat's hull.

The most critical factor here, without a doubt, is the mix ratio. If you’ve worked with polyester resin, you might be used to fudging the catalyst amount a bit. You can't do that with epoxy. The resin and hardener are designed to react at a very specific ratio, whether by volume or weight. Get it wrong, even by a little, and you've sabotaged the repair before you even start.

Mastering the Mix and Managing Time

I like to think of the resin and hardener as two different sets of puzzle pieces. If you have too many of one and not enough of the other, you're left with a bunch of unattached pieces. In epoxy, these are unreacted molecules that result in a weak, gummy, or brittle cure that will never reach its full design strength. Always use the pumps that come with your epoxy system or graduated mixing cups to measure exactly. No guesswork.

The second you combine the two parts, a chemical reaction starts, and the clock is officially ticking. This means you need to get a handle on two key concepts:

-

Pot Life: This is how long the mixed epoxy stays liquid in your mixing cup. The reaction creates its own heat (it's exothermic), and when it's all contained in a cup, that heat builds up and makes the epoxy cure faster. A big batch in a deep cup can get hot and kick off surprisingly quickly.

-

Working Time: This is the time you actually have to get the epoxy onto your repair surface before it starts to get tacky and unworkable. The trick is that spreading the epoxy into a thin layer lets that heat escape, which dramatically extends your working time well beyond its pot life.

A fantastic tip I picked up years ago is to mix epoxy in wide, shallow containers. A simple roller pan is perfect. It massively increases the surface area, lets the heat dissipate, and can easily double your working time. It makes the whole application process feel much less frantic.

Application Techniques for a Perfect Finish

Okay, you've got your perfectly measured epoxy and you know how much time you have to work with it. Now it's time to apply. For most fiberglass repairs, the goal is to completely "wet out" the cloth, saturating it with resin without trapping any air.

First, brush a thin coat of neat (unthickened) epoxy directly onto the prepped repair area. This primes the surface and helps the glass stick. Next, lay your pre-cut piece of fiberglass cloth into the wet resin.

Now, pour more epoxy over the top of the cloth. Use a plastic spreader or a squeegee to gently work the resin into the fabric. You're looking for the cloth to turn completely transparent, which tells you it's fully saturated. If you see any white, opaque-looking spots, it means that area is still dry and needs more resin.

This process of bonding and saturating the fiberglass is what gives an epoxy resin for boat repair its incredible strength. It’s also a big reason why the material is so essential in so many industries. In 2023, the global epoxy resin market hit around USD 11.25 billion and is expected to climb to USD 16.87 billion by 2030, all thanks to its amazing performance in coatings and composites. You can dig into the numbers and trends over on Grandview Research.

Using Fillers to Create Custom Compounds

Neat epoxy is great for wetting out fabric, but it’s too thin for filling gaps or shaping a structural fillet. For that, you need to thicken it with fillers, and different fillers give you different results.

| Filler Type | Primary Use | Sanding Ease |

|---|---|---|

| Colloidal Silica | High-strength bonding, filleting | Difficult to sand |

| Microballoons | Fairing, filling voids | Very easy to sand |

| Chopped Fibers | Reinforcing, adding impact resistance | Difficult to sand |

For example, when I need to create a strong, structural fillet (a rounded-out inside corner), I’ll mix in colloidal silica until the epoxy has the consistency of smooth peanut butter. But if I'm fairing a large area that needs to be perfectly smooth, I’ll use microballoons. This creates a much lighter, creamier paste that’s a dream to sand later.

Learning to use these fillers effectively is like unlocking a new level in your repair skills. It allows you to create the perfect custom compound for just about any situation your boat throws at you.

Finishing Your Repair for a Flawless Look

Sure, a structurally sound repair is what gets you back on the water safely. But let's be honest—a truly professional job is one that completely disappears. This final stage is all about the fine-tuning and finishing work. It’s where you blend your strong epoxy resin for boat repair into the boat’s original lines, restoring its looks along with its integrity.

Nothing says "pride of ownership" like a seamless fix that nobody can spot.

The real work begins after the epoxy is fully cured and rock-hard. Your first task is to shape and smooth the repair area, a process we call fairing. This means sanding down any high spots and filling any low spots to create a perfectly smooth, flowing surface that matches the surrounding hull. You’ll be knocking down excess epoxy and shaping any fairing compound you applied earlier.

The Art of Fairing and Sanding

Fairing is more art than science. It takes a bit of patience and a good eye for curves. I always, always start this process with a long sanding board, not a small block. A longboard is key because it bridges high and low spots, preventing you from accidentally creating new dips and waves in the surface.

Your choice of sandpaper grit is also critical. If you start with something too coarse, you’ll leave deep, stubborn scratches that are an absolute nightmare to remove later. I stick to a proven progression that gives me a glass-like finish every time.

My go-to sanding grit schedule looks like this:

- Start with 80-grit: This is aggressive enough to shape the cured epoxy and knock down any big high spots without being overly destructive.

- Move to 120-grit: After the initial shaping, this grit smooths out the 80-grit scratches and starts to really refine the surface.

- Finish with 220-grit: This is your final sanding step before primer. It creates a perfectly smooth surface that still has enough "tooth" for the primer to grab onto.

A pro tip: run your hand over the repair area constantly as you sand. Your fingertips are incredibly sensitive and will pick up on imperfections your eyes might miss.

The goal of fairing isn't just to make the patch smooth; it's to make it fair. That means it follows the natural, original curves of the hull without any flat spots or bumps. This is what truly makes a repair invisible.

Applying a Final Barrier Coat for Protection

Once you’re happy with the sanding, the entire area needs to be meticulously cleaned to get rid of every speck of dust. I use compressed air to blow the surface off, followed by a quick wipe with a tack cloth. Now, it's time for one final, thin coat of un-thickened liquid epoxy over the whole repair.

This final layer, often called a barrier coat, does two very important things. First, it fills any tiny pinholes or leftover sanding scratches, creating a perfect, non-porous surface. More importantly, it acts as a final moisture barrier and provides crucial UV protection for the repair work underneath, which is essential for long-term durability.

After this barrier coat has fully cured, give it one last, light sanding with 220-grit paper. That’s it. Your repair is now structurally complete, fully protected, and perfectly prepped. The surface is ready to accept marine primer and the final layers of paint or gelcoat, making all your hard work completely vanish into a flawless, professional-grade finish.

Common Questions on Epoxy Boat Repair

Even with the best instructions, a few questions always seem to surface when you're in the middle of a project, especially one as important as your boat. Let's tackle some of the most common questions I get about using epoxy resin for boat repair. These are the quick, clear answers you need to move forward with confidence.

Can You Apply Epoxy Over Old Paint or Gelcoat?

In a word: no. This is one of the most tempting shortcuts, but it's a critical mistake that will absolutely lead to a failed repair.

When you apply epoxy over paint or gelcoat, it’s only bonding to that surface layer. It's not bonding to the actual structure of your boat. That top layer can—and often does—peel or delaminate, taking your brand-new repair right along with it. For a strong, lasting fix, you have to grind or sand all the way down to the bare, raw fiberglass or wood. Epoxy needs a clean, textured surface to grab onto and create that powerful mechanical bond. Don't skip this step.

How Do You Know When Epoxy Is Fully Cured?

This is a great question, as cure times can really vary depending on the specific epoxy system and the temperature you're working in. Most epoxies will feel hard to the touch within a few hours, but reaching full structural strength is a different story. That can take anywhere from 24 hours to a full 7 days.

A good trick I've used for years is the "fingernail test." Press your fingernail firmly into the cured epoxy. If you can't leave a dent, it's generally hard enough to start sanding and finishing. But always, always double-check the product's technical data sheet for the official cure schedule.

What Happens If the Mix Ratio Is Slightly Off?

Unlike some other resins, epoxy chemistry is incredibly precise. Getting the mix ratio wrong, even slightly, means the repair will fail. There's no wiggle room here.

- Too much hardener: You might think this would make it cure faster, but it doesn't. It just leaves a bunch of unreacted chemicals in the mixture. The result is a weak, brittle patch that's prone to cracking under load.

- Too little hardener: This is just as bad. Without enough hardener, the chemical reaction stalls out, leaving you with a sticky, gummy mess that will never cure properly.

Always measure meticulously, either by volume or weight, exactly as the manufacturer instructs. Taking your time here is one of the most important boat maintenance tips every boat owner should know because it prevents a lot of wasted time and material down the road.

For all your repair and maintenance needs, Better Boat offers premium, easy-to-use products that deliver professional results. Get the right supplies for the job and keep your vessel in top shape.