How Does an Anchor Work A Complete Guide

It’s a common misconception, especially for new boaters, that an anchor is just a big, heavy weight you toss overboard to stop the boat. The reality is far more clever. An anchor works by digging into the seabed like a plow, not simply by being heavy.

This digging action creates immense resistance that grips the bottom, holding your boat securely against wind and currents. The secret to making this work is creating a horizontal pull on the anchor, which forces it to burrow deeper instead of yanking it out.

The Unseen Physics of How an Anchor Grips the Seabed

While weight certainly helps an anchor set, the real magic comes from two fundamental physics principles working in harmony: scope and the catenary effect. Once you get a feel for how these two forces interact, you’ll understand what's happening below the surface and trust your anchor to keep you safe.

Think of your anchor not as a dead weight, but as a carefully engineered tool designed to embed itself. Just like a farmer’s plow needs to be pulled at the right angle to dig into the soil, an anchor needs the correct angle of pull to grip the seabed. If you pull straight up, it’ll pop right out. This is where scope and the catenary effect come into play.

The Importance of Scope

Scope is the single most critical factor for successful anchoring. It’s simply the ratio between the length of your anchor line (known as the rode) and the vertical distance from your bow down to the seabed.

A short scope creates a steep, upward pull on the anchor—the fastest way to break it free and start drifting. A long scope, on the other hand, ensures the pull on the anchor is almost horizontal along the seabed. This is exactly what you want. That horizontal force drives the anchor's flukes (the spade-like points) deeper into the sand, mud, or gravel, maximizing its grip.

As a rule of thumb, most experienced boaters recommend a minimum scope of 5:1 for calm conditions. So, for every 10 feet of depth, you should let out 50 feet of rode.

- Calm Conditions: A 5:1 scope is a good starting point.

- Moderate Conditions: Bumping up to 7:1 gives you a much better margin of safety.

- Heavy Weather: In a serious blow, a scope of 10:1 or more might be necessary to stay put.

Understanding the Catenary Effect

The catenary effect is the natural curve or sag in a heavy anchor chain as it hangs between your boat and the anchor. This sag is your best friend in choppy water, acting as a built-in shock absorber.

When a gust of wind or a wave shoves your boat, it first has to lift the heavy chain before it can tug on the anchor itself. This dampens those sudden, violent jerks, transforming them into a slow, steady, and horizontal pull.

This keeps your anchor from getting shocked loose, allowing it to stay deeply buried and undisturbed. It’s the main reason an all-chain rode is so popular; the sheer weight of the chain creates a far more effective catenary curve than a lighter rope rode.

By combining a proper scope with the catenary effect, you create a system where the forces of nature actually help dig your anchor deeper, not pull it out.

Understanding Your Complete Anchoring System

It’s easy to think of an anchor as a standalone tool, but that’s a common mistake. In reality, the anchor is just one piece of a much larger, interconnected system called ground tackle.

Think of it like a team. The anchor might be the star player, but it can’t win the game alone. Every component, from the anchor buried in the seabed all the way to the cleat on your deck, has a critical role.

Together, they manage the powerful forces of wind and current, allowing your anchor to do its job: dig in and hold you steady. If one part of that system fails, the whole setup is compromised.

The Three Core Components

Your ground tackle is built around three essential parts. Each one is designed to create the horizontal pull and shock absorption your boat needs to stay put safely.

- The Anchor: This is the business end of the operation, the tool designed to penetrate the seabed. Its specific shape, weight, and flukes are all engineered to bite into different bottoms, whether that's sand, mud, or rock. The right design will set quickly and dig even deeper when the load increases.

- The Chain: Connected directly to the anchor shank, the chain is the system's muscle. Its sheer weight is what creates the all-important "catenary curve"—that gentle sag in the line that acts as a natural shock absorber. This keeps the pull on the anchor horizontal, which is exactly what you want. It's also incredibly tough, standing up to abrasion from rocks and coral.

- The Rode: This is the line that connects the chain to your boat. It can be all chain, all rope, or a combination of the two. If rope is used, nylon is the go-to choice. Its natural stretchiness adds another layer of shock absorption, which is a huge benefit when you’re getting tossed around in rough seas.

The real magic happens when these components work in harmony. A top-of-the-line anchor is useless if you pair it with a flimsy chain or don't let out enough rode. Your anchoring system is only ever as strong as its weakest link.

Why Every Part Matters

Let’s run a little thought experiment. Imagine trying to anchor with just a rope tied directly to your anchor shank. Without the heavy chain to weigh it down, every gust of wind would yank that rope taut, pulling up on the anchor. It wouldn't take much to pop it right out of the seabed.

The chain is that crucial middleman. It takes those jarring, vertical forces and transforms them into a steady, manageable horizontal pull.

The anchor itself is just as critical. Using a lightweight fluke-style anchor on a rocky bottom is like trying to plow a field of boulders with a garden hoe—it just isn't going to dig in. This is why knowing how to choose an anchor for your specific boat and where you plan to cruise is one of the most fundamental skills any boater can learn.

When you take the time to optimize each piece of your ground tackle, you create a balanced system that works with physics, not against it.

What Marine Anchors Can Learn From Construction Anchors

To really get a handle on how a marine anchor works, it helps to look away from the water for a moment and into a completely different field: construction. The basic idea of creating massive holding power by grabbing onto a surface isn't unique to boating. In fact, the mechanical anchors used to bolt structures to solid concrete offer a fantastic parallel.

Instead of digging into sand or mud, a construction anchor grips the inside of a pre-drilled hole. It’s not about sheer weight; it’s all about generating incredible force through friction and expansion. This concept is a great lesson in the physics of grip, which is exactly how your boat’s anchor secures itself to the seabed.

Friction and Expansion: The Universal Principles

Think about a common wedge anchor. This is basically a threaded stud with a special clip and a tapered cone at the bottom. Once you slide it into a drilled hole in concrete, tightening the nut pulls that cone upward. This forces the clip to expand and press outward against the concrete walls with immense pressure.

This expansion creates enormous friction, locking the anchor in place. The holding power is huge, but it's completely dependent on a few key things: a clean hole, the right drill bit size, and the correct tightening torque. This is a direct mirror of how your marine anchor’s performance hangs on the right seabed type and proper setting technique. In both worlds, the system fails if the initial setup is sloppy.

An anchor, whether it’s in concrete or on the seabed, is a tool designed to convert one type of force into another. It transforms a simple pull into a powerful, immovable grip by interacting intelligently with its environment.

Mechanical anchors get their strength from friction, created by expanding inside a hole. These anchors, usually made from carbon or stainless steel, press so tightly against the concrete that they create significant resistance to being pulled out.

For these to work correctly, standard embedment depths often need to be at least 9 times the diameter of the threaded bar. On top of that, they typically use a safety factor of around 4:1 to guarantee a safe working load. If you want to dive into the technical side, this Field Manual for Concrete Anchoring has all the details.

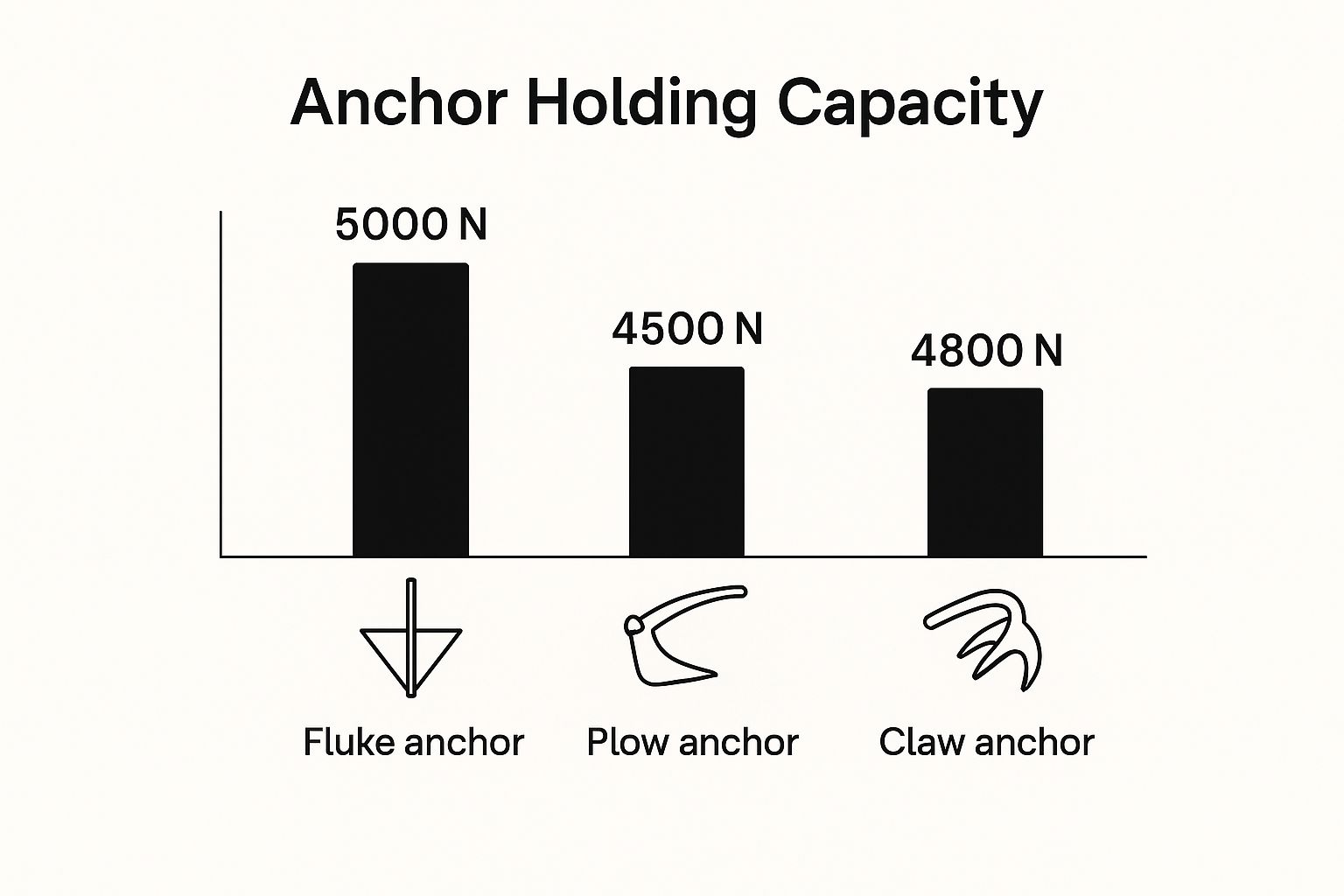

This image shows the typical holding capacity for three popular marine anchor styles in ideal conditions.

While the numbers are in the same ballpark, they show how small design differences in anchors styles, weights, and materials can lead to big variations in real-world performance.

The main takeaway here is universal: an anchor’s only job is to create resistance. It doesn't matter if it’s a wedge anchor expanding in concrete or a plow anchor digging into sand—the goal is identical.

Understanding this core concept helps you appreciate that anchoring isn't just about dropping a heavy object overboard. It’s about applying a proven engineering principle to stay put, no matter what the wind and waves throw at you.

How Modern Anchors Are Engineered for Performance

Anchor technology is anything but static; it's a field of constant engineering refinement. Modern anchors are designed with a single goal in mind: set faster, dig deeper, and hold more reliably across a wider range of seabeds than their predecessors ever could. It’s all about performance and safety.

This obsession with performance has led to some serious design breakthroughs. Unlike older, more passive designs, new-generation anchors are engineered to be active, intelligent tools. They use physics and geometry to their advantage, ensuring they orient themselves correctly the moment they hit the bottom.

Smart Design for Instant Setting

One of the most visible innovations is the roll-bar. Made popular by brands like Rocna, this simple-looking hoop ensures the anchor always lands on the seabed in the perfect orientation, ready to dig in. It completely solves the frustrating problem of an anchor landing upside down and refusing to set—a common headache with older designs.

This self-righting capability means the anchor starts working almost instantly. The flukes—the spade-like digging parts—are precisely shaped with sharp, weighted tips to penetrate even tough seabeds like packed sand or weedy bottoms.

The geometry of the fluke is critical. Modern designs use concave shapes that act like a scoop, gathering seabed material to generate immense holding power far exceeding what their weight alone could provide.

This focus on intelligent engineering isn't just happening on the water. The construction world has seen similar advancements that improve both safety and efficiency.

Borrowing from Advanced Construction Tech

The same principles of superior grip and ease of use are found in modern mechanical anchors for construction. Big innovations in this field have dramatically improved both installation speed and how much load they can handle.

For instance, some heavy-duty screw anchors are engineered for demanding situations like cracked concrete and seismic zones. Instead of relying on expansion, they’re designed to cut their own threads directly into the concrete as they're screwed in. This slick design eliminates extra steps, reduces labor costs, and allows for immediate load application. You can learn more about these powerful Simpson Strong-Tie mechanical anchors.

Whether it's on a boat or a building site, the goal is the same: create the most reliable holding power possible through smart, purpose-built design.

Mastering the Art of Anchoring Your Boat

Turning what you know in theory into a real, practical skill is what separates a good boater from a great one. Understanding how an anchor works is only half the battle. The other half is knowing how to deploy it correctly. This isn't just about heaving it over the side—it's a deliberate process that ensures your anchor digs in deep and keeps you right where you want to be.

Proper technique starts long before your anchor ever hits the water. It begins with picking the right spot and getting your gear ready. A few minutes of prep can save you from hours of frustration or, even worse, a long night wondering if you're dragging.

Choosing the Perfect Spot

Where you decide to drop anchor is just as important as the anchor itself. The first thing to do is pull out your charts and figure out what the seabed is made of. An anchor designed for sand is going to have a rough time in rock, so knowing what’s down there is absolutely critical.

Next, you have to think about the conditions. Take a look at the wind and current, but don't just consider where they are now—think about where they'll be in a few hours. Always approach your spot with your bow pointing into the wind or the current, whichever is stronger.

Finally, give yourself room to breathe. Lots of it. As the conditions shift, your boat is going to pivot around the anchor. You need to be sure you have a clear 360-degree circle around your boat with zero obstacles.

Setting the Anchor with Confidence

Once you've picked your spot, it's time to set the hook. Follow these steps, and you'll get a solid hold just about every time.

- Approach Slowly: Motor gently upwind or up-current, just past where you want to drop.

- Stop and Drift: Bring the boat to a complete stop and let it start drifting backward over your target.

- Lower, Don't Throw: Pay the anchor out smoothly until you feel it touch the bottom. Just chucking it overboard is a great way to get the chain tangled around the anchor itself.

- Pay Out Rode: As you drift back, let the rode out. Don't let it all go slack; keep just a little bit of tension on it. This helps the anchor lie down and orient itself correctly on the seabed.

The single most important part of this whole process is making sure the anchor is truly set. After you've let out the right amount of scope, gently bump the engine into reverse at idle. You should feel the anchor dig in and the line pull taut. That's how you know you've got a firm grip.

For a much deeper dive into the fine points of this process, check out our comprehensive guide on how to anchor a boat. It’s packed with even more detailed steps and pro tips.

Avoiding Common Anchoring Mistakes

Most anchoring headaches come from a few simple, totally preventable mistakes. Just being aware of them will help you sleep a lot better at night.

- Misjudging the Bottom: A lot of people assume the bottom is sand when it's really rock or covered in thick weeds. This is a classic blunder that leads to poor holding power. Always, always check your charts.

- Not Using Enough Scope: This is probably the #1 cause of anchoring failure. A 5:1 scope is the bare minimum for calm weather. As conditions start to get choppy, you'll want to increase that to 7:1 or more.

- Failing to Confirm the Set: Just dropping the anchor and hoping for the best is a recipe for a dragging disaster. Always use a little reverse power to make sure it’s dug in securely.

Frequently Asked Questions About Anchoring

Even when you feel like you've got the hang of anchoring, questions always pop up out on the water. It's just part of boating. Here are some straightforward answers to the queries we hear most often, touching on the core principles of keeping your boat safe and secure.

Think of these as quick solutions for the real-world situations you’re likely to face.

What Is the Best Anchor for Sand?

When you’re dealing with a sandy bottom, you need an anchor that’s built to dig in and bury itself deep. That’s where plow-style and scoop-style anchors really shine.

Models like the CQR, Delta, Rocna, and Mantus are engineered with shapes that slice right into soft seabeds. Their design gives them incredible holding power where other anchor types might just skid along the surface, struggling to get a good grip.

Your choice of anchor should always be guided by the seabed you visit most. A specialized anchor, like a plow for sand, will dramatically outperform a general-purpose model when it’s in its element.

How Much Anchor Line Do I Really Need?

The amount of line you let out—what boaters call scope—is absolutely critical. A solid rule of thumb for calm, predictable weather is a 5:1 scope. What that means is for every foot of depth from your bow down to the seabed, you need to pay out five feet of rode.

But when the wind kicks up or the seas get choppy, you need more. A lot more. Upping your scope to 7:1 or even higher is the smart move. This extra line ensures the pull on the anchor stays horizontal, forcing it to dig deeper rather than getting yanked out of the bottom. When in doubt, always let out more scope.

How Can I Tell If My Anchor Is Dragging?

There are a couple of reliable ways to know if your anchor is dragging. The old-school method is to take bearings on two fixed objects on shore, like a lighthouse and a prominent tree. If the angle between those two points starts to change, your boat is on the move.

The more modern approach is to use your boat's GPS to set an anchor alarm. This handy feature creates a virtual circle around your boat and will blast an alert if you drift outside of it. It’s an immediate warning that your anchor has lost its hold and you need to reset it.

For all your anchoring gear and boat care essentials, you can count on Better Boat for premium, reliable products. From tough anchor lines to high-performance cleaners, we have what you need to keep your vessel in prime condition. Check out our full range of gear at https://www.betterboat.com.