How to Winterize an Inboard Outboard Motor: Easy Steps to Protect Your Boat

When it's time to put your boat away for the season, a proper winterization of your inboard outboard motor isn't just a suggestion—it's essential. The process boils down to a few key tasks: flushing the cooling system, getting every last drop of water out, running marine-grade antifreeze through it, stabilizing the fuel, changing the oil, and fogging the engine cylinders.

It might sound like a lot, but this is the single most important maintenance you'll do all year. Skipping these steps is a surefire way to face catastrophic—and incredibly expensive—engine damage like freeze cracks and internal corrosion.

Why Winterizing Your Sterndrive Is Critical

Letting your sterndrive fend for itself when the temperature drops is one of the biggest gambles you can take as a boat owner. It's a direct path to serious engine damage, all thanks to a simple law of physics: when water freezes, it expands by about 9%.

That expansion creates an unstoppable force, powerful enough to crack a multi-thousand-dollar engine block or exhaust manifold from the inside out.

Many boaters think this is only a problem for those of us up north dealing with snow and ice. The hard truth is that a single, unexpected cold snap in a milder climate can cause just as much irreversible harm to an unprepared engine. This is exactly why learning how to winterize an inboard outboard motor is a non-negotiable skill for every owner.

The Real Cost of Neglect

The stakes are sky-high. A cracked engine block isn't a simple patch job; it usually means a complete and costly engine replacement is in your future.

Think about the weak points where water loves to hide:

- Engine Block: Any water left in the cooling passages will freeze, expand, and crack the cast iron.

- Exhaust Manifolds: Just like the engine block, these parts have water jackets that are extremely vulnerable to freeze damage.

- Cooling Hoses: That expanding ice can easily split rubber hoses, setting you up for major leaks come springtime.

The surprising truth is that freeze damage isn't just a cold-weather problem. It's a "lack of preparation" problem that can happen anywhere temperatures dip toward freezing.

Here’s a fascinating tidbit from insurance claim stats. According to BoatUS data, some of the states with the most freeze-related damage claims are often warmer spots like California and Florida, not just the usual cold-weather states. It’s a strange paradox, but it makes sense—boaters in milder climates are often less prepared and might skip winterization entirely.

Protecting your investment starts with knowing the specific vulnerabilities of the inboard outboard design. To get a better handle on how these systems operate, take a look at our complete guide on inboard outboard motors. When all is said and done, winterization is your best defense against a springtime disaster.

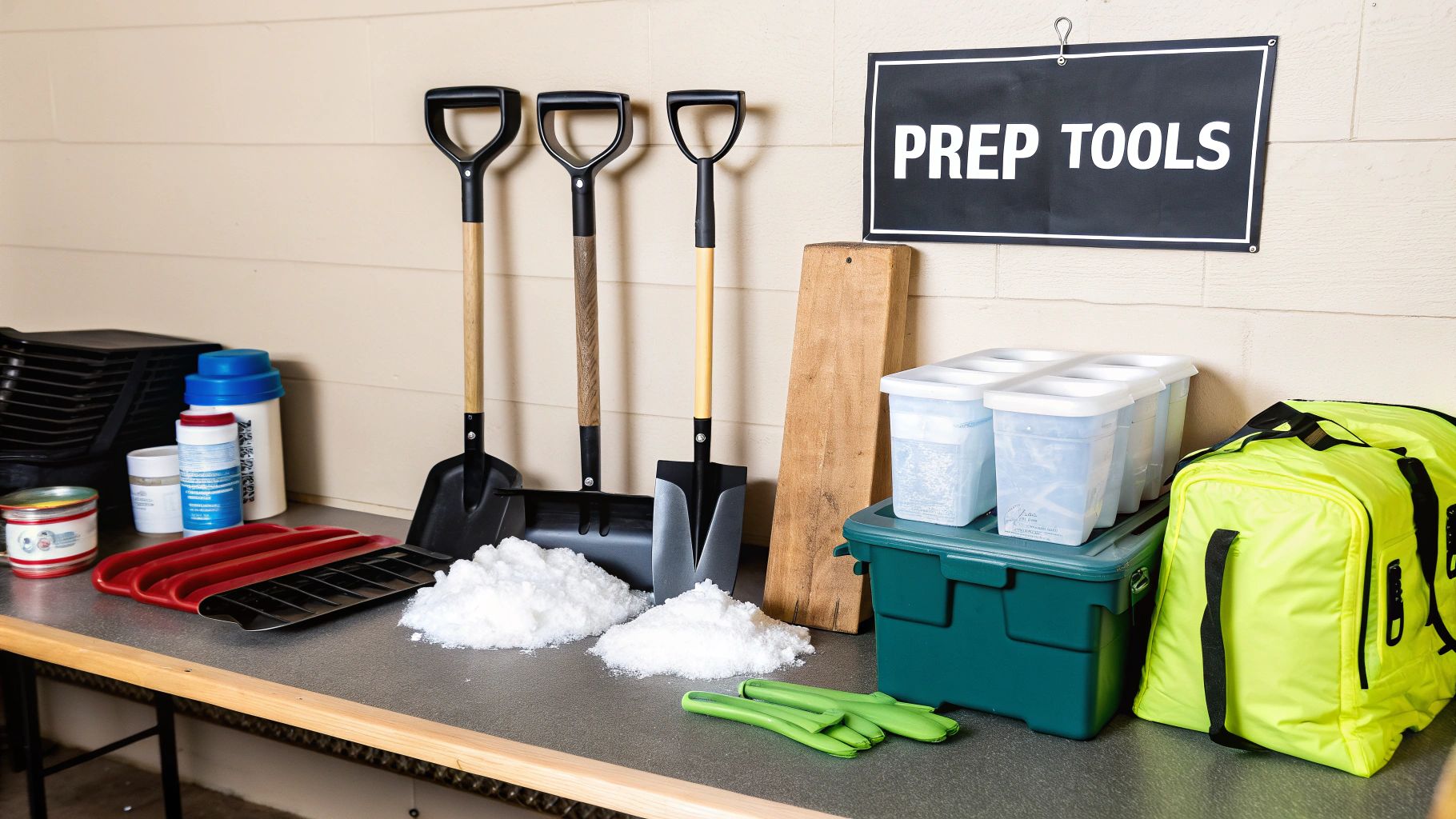

There’s nothing worse than getting halfway through a job only to realize you’re missing a critical tool. Trust me, I’ve been there. A little prep work gathering your supplies before you start will save you a ton of headaches and last-minute trips to the marine store.

Think of this as assembling your winterization toolkit. Getting everything laid out and ready to go turns what can feel like a chore into a smooth, step-by-step process.

Your Complete Sterndrive Winterization Checklist

Before we dive into the nitty-gritty, let's get your shopping list sorted. Having the right gear on hand is non-negotiable for doing this job safely and effectively. The table below breaks down everything you'll need, from basic tools to the specific fluids that will protect your engine all winter long.

| Item | Recommended Type | Purpose and Key Considerations |

|---|---|---|

| Marine Antifreeze | Non-toxic, propylene glycol-based (-50°F or -100°F) | Displaces water in the cooling system to prevent freeze damage and inhibit corrosion. Choose a temperature rating appropriate for your climate. |

| Fuel Stabilizer | Marine-specific formula | Prevents fuel degradation and phase separation during storage, protecting your entire fuel system from varnish and gum buildup. |

| Fogging Oil | Aerosol spray can | Coats internal cylinder walls, pistons, and rings with a protective layer of oil to prevent rust and corrosion from forming during the damp off-season. |

| Engine Oil & Filter | Manufacturer-recommended weight (e.g., 25W-40) | Changing the oil removes acidic contaminants and moisture, protecting internal engine parts from corrosion during storage. |

| Gear Lube | Marine-grade gear oil (e.g., 80W-90) | Protects the lower unit gears. Draining the old lube is also a critical diagnostic check for water intrusion, which indicates a failing seal. |

With these core supplies in your arsenal, you're well on your way. Now, let's talk about the specific tools that make handling these fluids a clean and simple job.

Key Tools for the Job

You can't just pour this stuff in and hope for the best. A few specific tools are essential for getting the old fluids out and the new ones in without making a huge mess.

- Oil Extractor Pump: Most sterndrives don’t have a simple drain plug on the oil pan like your car does. An extractor pump is the only clean way to get the old oil out by pulling it up through the dipstick tube.

- Oil Filter Wrench: Don't even try to remove an old oil filter by hand. They get slick and are often tightened down in a hard-to-reach spot. This tool gives you the grip you need.

- Motor Flushing Muffs: Often called "ear muffs," motor flushing muffs are absolutely critical. They clamp over the water intakes on your lower unit and connect to a garden hose, allowing you to safely run the engine out of the water to circulate fluids.

Why Marine-Specific Fluids Are a Must

This is where a lot of new boat owners get tripped up, and it's one of the most important parts of the whole process. You cannot substitute automotive products for their marine counterparts, especially when it comes to antifreeze.

CRITICAL: Never, ever use standard automotive antifreeze (ethylene glycol) in your boat's engine. It is highly toxic to aquatic life. Even a small amount discharged in the spring can cause serious environmental damage.

Always use a non-toxic, propylene glycol-based marine antifreeze. It’s specifically designed to protect your engine from freezing and corrosion without poisoning the ecosystem when you de-winterize next season. It's a simple choice that makes a huge difference.

A Practical Guide to Engine Winterization

Alright, time to roll up our sleeves and get to the heart of the matter. This is where we move from planning to doing, and I'll walk you through not just what to do, but why you're doing it. Getting this right is what separates a smooth spring launch from a season of headaches.

First thing's first: we need to get the engine warmed up. Cold oil is thick like molasses and won't drain properly. You want it warm and fluid so it can carry all the nasty gunk and moisture out with it. This is a job for your motor flushing muffs.

Get the muffs fitted snugly over the raw water intakes on your lower unit. Hook up a garden hose, turn the water on, and—this is critical—make sure you've got good water flow before you even think about turning the key. Firing up the engine dry, even for a moment, can absolutely shred your water pump's impeller.

Stabilizing the Fuel System

With the engine happily running on the muffs, it's the perfect time to tackle the fuel system. Grab your marine fuel stabilizer and pour the right amount for your fuel tank's capacity straight in.

Let that engine run for a good 10-15 minutes. This does two very important things at once. It gets the engine up to operating temperature for the oil change we're about to do, and it pulls that freshly stabilized fuel through the entire system—fuel lines, pumps, filters, and right into the carburetor or injectors. This is your insurance policy against gum and varnish deposits forming over the winter.

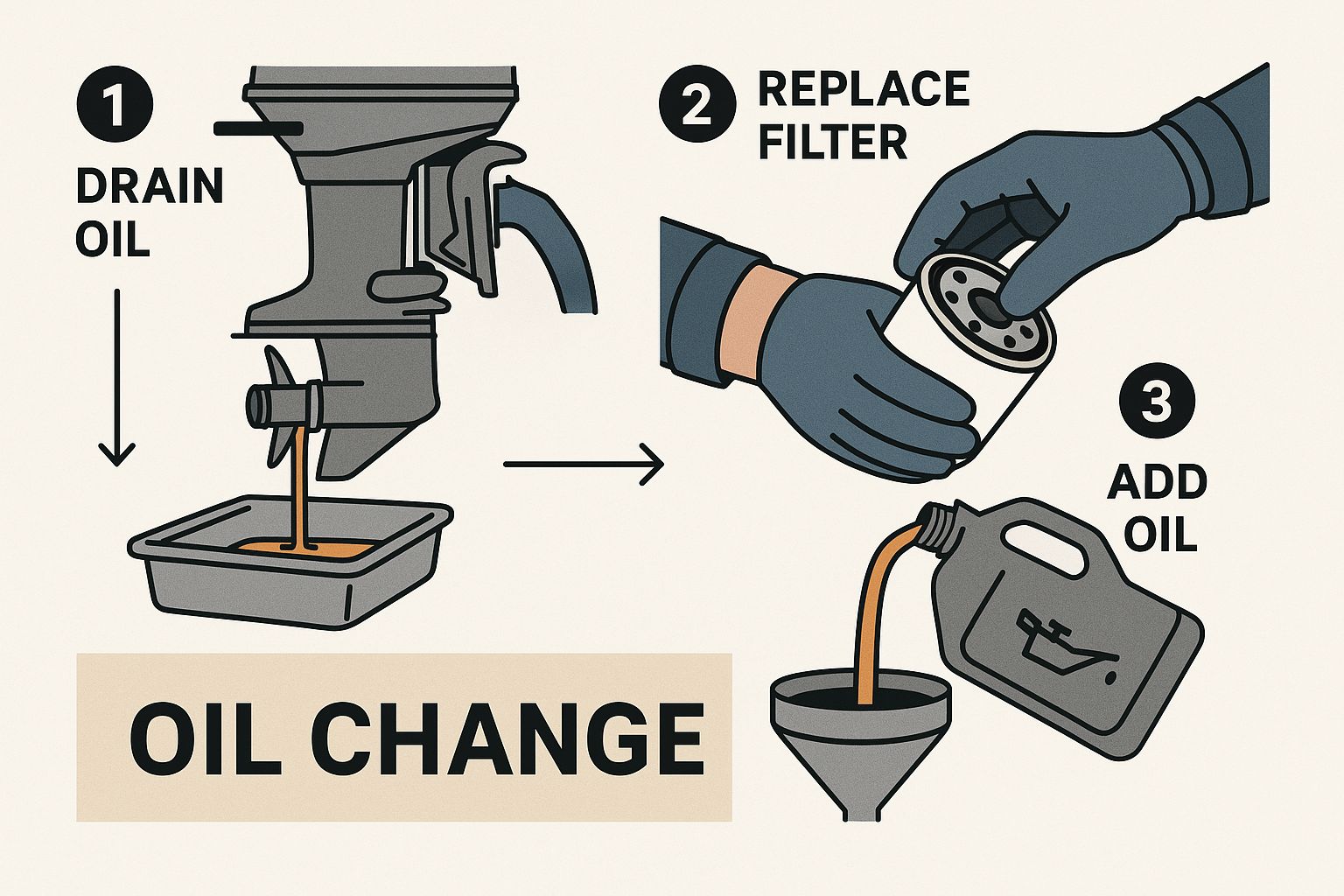

Performing the Off-Season Oil Change

Once the engine is nice and warm, go ahead and shut it down. Now we're ready for what I consider the single most important oil change of the year. That old, used oil is loaded with moisture and acidic contaminants that will gladly eat away at your engine's bearings and internal parts if you let it sit all winter.

Grab your oil extractor pump, feed the tube down the dipstick hole, and pump every last drop of that old oil into a container you can take for proper recycling. With the old stuff out, swap in a new oil filter. I always put a little film of new oil on the filter’s rubber gasket before I spin it on—it helps create a perfect seal.

The infographic below really captures the hands-on nature of this critical step.

As you can see, getting that contaminated oil out is non-negotiable for preventing internal corrosion. Once the new filter is on, refill the engine with fresh marine-grade oil, using the weight and amount your manufacturer specifies.

Draining the Cooling System

With the oil handled, we move on to what is arguably the most critical step for preventing catastrophic freeze damage: getting every bit of water out of the engine block and manifolds. Any water left behind will freeze, expand with incredible force, and crack those very expensive parts.

Now it's time to locate your engine's drain plugs. Every engine is a little different, but you'll generally find them on the sides of the engine block and at the lowest point on the exhaust manifolds.

Pro Tip: Have a small, stiff piece of wire handy. It's really common for these drain holes to get clogged with sediment or bits of rust. Gently poke the wire into the hole to clear any blockage and make sure you get a complete drain.

Pull all the plugs and let the water pour out. It's also a good idea to disconnect the main circulation hose at its lowest point to make sure it's completely empty.

Circulating Marine Antifreeze

Even with a thorough drain, you'd be surprised how much water can get trapped in little nooks and crannies. This is why just draining isn't enough protection. You need to circulate a proper marine-grade antifreeze through the system to push out that last bit of water and add a layer of corrosion protection.

Here’s how you set up a simple closed-loop system to do this:

- First, reinstall all the drain plugs you just took out. Make them snug.

- Find the main raw water intake hose (the one that runs from the sterndrive to the engine's water pump) and disconnect it.

- Stick the end of that hose into a five-gallon bucket filled with non-toxic marine antifreeze.

- Fire up the engine. It will start sucking the antifreeze right out of the bucket and into the cooling system.

Keep an eye on the exhaust ports. When you see that distinct pink (or sometimes blue) color of the antifreeze spitting out, you'll know it's made its way through the entire system. This is a fundamental technique we touch on in our broader guide on how to properly flush a boat engine.

Fogging for Internal Protection

Our last step is to protect the engine's internals from rust. We do this by "fogging" the cylinders. Fogging oil is a special waxy oil that coats everything—cylinder walls, pistons, rings—and stops condensation from causing rust during storage.

While the engine is still running (sucking up that last bit of antifreeze), spray the fogging oil right into the carburetor or throttle body intake. You'll see the engine start to bog down and produce a ton of white smoke. That's exactly what you want to see.

Keep spraying for about 10-15 seconds, or right up until the engine chokes and stalls. That's the sign that everything is nicely coated. If you want to be extra thorough, you can also pull the spark plugs, give a quick shot of fogging oil into each cylinder, and then turn the engine over a couple of times by hand to spread it around.

With the engine tucked in for its long winter nap, it's time to turn your attention to the business end of your boat: the sterndrive's lower unit. This is where the power meets the water, and it's got its own set of risks to deal with over the offseason, from sneaky corrosion to catastrophic seal failures.

Give Your Prop and Lower Unit a Good Once-Over

First things first, let's talk about the propeller. Get in there and give every blade a careful inspection. You're looking for nicks, dings, and even slight bends. It might not look like much, but even a tiny bit of damage can throw the prop's balance off, creating vibrations that will chew up your seals and bearings next season.

I always recommend taking the propeller off completely for the winter. It makes it way easier to check the propshaft seals for any tangled-up fishing line, and let's be honest, it's a great theft deterrent.

Check Your Bellows and Bearings

With the prop out of the way, you've got a clear shot at some of the sterndrive's most critical—and vulnerable—parts. Zero in on the rubber bellows, those corrugated boots that look like an accordion. They're all that stands between the water and some very expensive parts.

- U-Joint Bellows: This is the big one. Squeeze it, flex it, and look for any cracking, splits, or signs of dry rot. A bad U-joint bellow is one of the top reasons for catastrophic drive failure. Water gets in, and your U-joints are toast.

- Exhaust Bellows: Give this one a check for cracks, too. A failure here is less of an emergency than the U-joint bellow, but it's still something you want to catch early.

- Shift Cable Bellows: This little boot is easy to overlook, but a tear lets water right into your shift cable. That leads to corrosion, a stiff shifter, and a real headache come springtime.

While you're down there, reach into the housing and give the gimbal bearing a spin. It should feel perfectly smooth. If you feel any roughness, grinding, or a "notchy" sensation as it turns, that bearing is shot. Get it on your to-do list for replacement before you hit the water next year.

The Most Important Check: Changing Your Gear Lube

This isn't just routine maintenance; changing the gear lube is your single best diagnostic tool for the health of your lower unit. Grab a drain pan, position it under the sterndrive, and remove both the upper (vent) and lower (drain) screws.

Pay very close attention to that first little bit of oil that trickles out. If it looks milky, creamy, or like coffee with way too much cream, stop right there. You've got a serious problem: water has gotten into the lower unit, which means a seal has failed somewhere.

This is a must-fix issue before you store the boat. If you leave a drive with water in the gear case all winter, that water will freeze, expand, and can easily crack the entire gear case housing. That's how a simple seal replacement turns into a repair bill with a comma in it.

If the oil comes out looking clean and dark (like new oil, but, well, used), you can breathe a huge sigh of relief. Let it all drain out. Then, using a gear lube pump, fill from the bottom hole until you see fresh lube coming out of the top vent hole. Put the top vent plug back in first, then quickly remove the pump and screw in the bottom drain plug. Wipe it clean, and you're good to go.

Final Steps for Secure Winter Storage

With all the mechanical work out of the way, it's time to button everything up. These last few jobs are just as important as changing the oil or flushing the engine. They’re what protect your boat from the silent, slow-moving damage caused by moisture, pests, and general neglect over the long winter months. A little effort here saves a ton of headaches in the spring.

First on the list is your battery. Leaving it hooked up in a cold, damp boat all winter is a surefire way to kill it. Cold temperatures naturally drain lead-acid batteries, and if a battery discharges completely, it can freeze, crack, and leak acid all over your bilge. It’s a mess you don’t want to deal with.

The absolute best practice is to pull the battery out entirely. Disconnect the terminals and bring it home. Find a cool, dry spot for it in your garage or basement—just make sure it’s not sitting directly on a concrete floor. Hook it up to a battery tender (or a smart trickle charger) for the winter. This little device will keep it topped off with a low, steady charge, ensuring it's healthy and ready to go when you are.

Preventing Mold and Pests

Your next major enemy during storage is moisture. Condensation gets trapped under a boat cover and creates the perfect humid environment for mold and mildew. Once that stuff gets into your upholstery, it’s a nightmare to remove, and the musty smell can linger forever.

A good, thorough cleaning is your first line of defense. Before that cover goes on, get the interior completely clean and bone-dry. Pull out any damp life jackets, towels, or other gear. Once it’s clean, scatter a few moisture absorbers around. Products like Dri-Z-Air canisters work wonders in a few key spots:

- Down in the cabin or cuddy

- Tucked inside storage lockers

- Near the bilge area

Your goal is to keep the air inside the boat as dry as possible. A well-ventilated cover is key—it should fit snugly but still allow air to circulate, preventing the greenhouse effect that traps moisture.

Last but not least, you’ve got to think about pests. To a mouse or a squirrel, your stored boat looks like a five-star winter resort, complete with fluffy nesting material—your vinyl seats. They can chew through wiring, upholstery, and plastic in no time, causing thousands in damage.

Deter them by placing repellents throughout the boat. I’ve seen boaters have great success with all sorts of things, from cotton balls soaked in peppermint oil to commercially available rodent repellents. Some old-timers even swear by scattering bars of Irish Spring soap in every compartment. The strong smells drive them away and encourage them to find shelter somewhere else.

For a complete rundown of everything you should be doing, our comprehensive winterize boat checklist is a fantastic resource to make sure you don't miss a single step.

A Few Common Winterizing Questions

Even after you've winterized a few boats, some questions always seem to come up. Getting the right answers is the difference between a smooth spring launch and a season-opening headache. Let's clear up some of the most common things boaters ask.

Do I Really Need Antifreeze if I Drain All the Water?

Yep, you absolutely do. Even with a thorough drain, it’s practically impossible to get every last drop of water out of all the little nooks and crannies inside the engine block. That tiny bit of leftover water is more than enough to freeze, expand, and crack your engine block or manifold—a truly catastrophic failure.

Think of marine antifreeze as more than just freeze protection. It's designed to push out that residual water and coat all the internal metal parts with a layer of corrosion inhibitor. It’s your engine’s best defense against the damp, cold months ahead.

Can I Use Car Antifreeze in My Boat Engine?

This one is a hard no. You should never use automotive antifreeze, which is ethylene glycol-based, in your boat's engine. It's incredibly toxic to fish and other aquatic life. Any discharge of it come springtime could do serious damage to the local ecosystem.

Stick with a non-toxic, propylene glycol-based marine antifreeze. It's made specifically for this job, giving you the freeze protection you need without poisoning the water you love to boat on.

Forgetting fuel stabilizer is one of the most common and costly winterizing mistakes. Modern ethanol-blended fuel can begin to degrade in as little as 30 days, leading to a process called phase separation where water and ethanol sink to the bottom of your tank, ready to corrode your fuel system.

Is a Full or Empty Fuel Tank Better for Storage?

The best practice here is to store your boat with the fuel tank about 90% full, right after you've mixed in a good fuel stabilizer. Why? A nearly full tank leaves very little room for air. Less air means less space for condensation to form as the temperature swings up and down all winter. And less condensation means less water getting into your fuel to cause problems.

Of course, getting the motor ready is just one piece of the puzzle. It's also smart to brush up on the best practices for long-term vehicle storage in general. You can learn more about how to store your vehicle safely when not in use to make sure every part of your rig is protected.

Here at Better Boat, we know the right products make the job easier and more effective. Our marine-grade Fuel Stabilizer is engineered to stop the harmful effects of ethanol and phase separation dead in their tracks, so you can count on a quick, clean start next season. Protect your investment by heading over to Better Boat to grab a bottle today.