Safely Use Acid to Remove Rust From Your Boat

Yes, certain acids are an incredibly effective way to chemically dissolve rust (iron oxide) right off your boat's surfaces. Forget abrasive methods that physically scrape away metal.

Acids like phosphoric and oxalic trigger a chemical reaction that converts the rust into a water-soluble compound. This makes it a breeze to just rinse it away without harming the good surface underneath.

Understanding How Acid Solves Marine Rust

Before you grab a bottle of rust remover, it helps to understand what's actually happening at a chemical level. This knowledge will get you much better results. Rust isn't just an ugly orange stain; it's a process called oxidation, where iron or steel reacts with oxygen and moisture.

The marine environment, especially saltwater, is an aggressive catalyst for this reaction. The salt acts as an electrolyte, dramatically speeding up the electron transfer that causes iron to corrode. That's why a tiny scratch on your boat’s stainless steel railing can bloom into a massive rust stain way faster than it would on land.

The Chemistry of Rust Removal

This is where the magic of using an acid comes in. Instead of trying to physically grind away the rust—a method that often scratches and weakens the metal—acids work smarter, not harder.

- Targeted Reaction: Acids like phosphoric and oxalic are formulated to go after iron oxide specifically. They kick off a chemical reaction that breaks down the molecular bonds holding the rust together.

- Conversion Process: The acid converts the solid, flaky rust into a water-soluble salt, like iron phosphate. This new compound can't stick to the metal anymore and is easily wiped or rinsed away.

- Surface Preservation: Since this process is chemical, not mechanical, it cleans deep into the microscopic pits and crevices of the metal without creating new scratches or gouges.

This chemical approach is why you see acid-based rust removers everywhere. The global rust remover market was valued at around USD 411.6 million back in 2017 and is projected to hit USD 638.9 million by 2027. Acid-based products make up over 50% of that market because, simply put, they work.

Common Acids for Marine Rust Removal

Not all acids are created equal. Different formulations are better suited for different jobs around the boat. Here's a quick rundown of what you'll typically find in marine rust removers.

| Acid Type | Best For | Key Feature |

|---|---|---|

| Phosphoric Acid | Stainless steel, chrome, preparing metal for paint | Converts rust and leaves a protective phosphate coating. |

| Oxalic Acid | Gelcoat stains, fiberglass, wood ("wood bleach") | Excellent for removing those stubborn yellow/brown stains. |

| Hydrochloric Acid | Heavy-duty rust on non-sensitive metals (use with caution) | Extremely powerful and fast-acting, but highly corrosive. |

| Citric Acid | Light rust on sensitive surfaces, tools | A milder, more environmentally friendly option. |

Knowing which acid is in your product helps you choose the right tool for the job and use it safely. For example, our Instant Hull Cleaner utilizes oxalic acid, making it a highly effective and safe choice for tackling rust stains on fiberglass and painted surfaces.

Why Not Just Sand It Off?

Sanding or grinding rust off seems like a straightforward fix, but it comes with some serious downsides, especially on a boat. Abrasive methods don't just take off the rust; they also remove a thin layer of healthy metal with it.

This creates a fresh, scratched-up surface that's often more susceptible to future corrosion than the original polished finish. For a deeper dive into this cycle, our guide on fighting salt corrosion on boats explains why a smooth, protected surface is your best defense.

Using an acid-based cleaner ensures you're only removing the unwanted oxide layer. It leaves the healthy metal underneath untouched and often creates a passivated surface that is more resistant to immediate re-rusting, giving you time to apply a protective coating.

Ultimately, understanding the science helps you make a smarter choice. You can use an acid-based remover confidently, knowing you're actually solving the problem, not just creating a new one by damaging your boat's valuable finishes.

Your Essential Safety and Prep Checklist

When you grab a bottle of acid to tackle rust, you're working with some seriously powerful chemistry. This isn't the time to cut corners. Handling these chemicals demands respect and a solid game plan. Skipping the safety prep isn't just a bit risky—it’s a surefire way to end up with chemical burns, eye damage, or a permanently scarred patch on your boat's beautiful finish.

So, before you even think about cracking that seal, let's walk through how to set yourself up for success and safety. This is more than just a checklist; it's about understanding why each piece of gear matters. If you're new to this, it's a good idea to do a comprehensive chemical risk assessment to get a clear picture of what you're dealing with.

Assembling Your Personal Protective Equipment

Your first line of defense is what you're wearing. Let me be clear: your everyday work gloves and sunglasses are not going to cut it here.

- Chemical-Resistant Gloves: Go for nitrile or neoprene gloves. Latex can break down when it comes into contact with certain acids, but these materials will give you a reliable barrier.

- Splash-Proof Goggles: Regular safety glasses leave gaps. You need fully sealed, splash-proof goggles that protect your eyes from every angle. An unexpected drip or a little fizz-up can happen in a split second.

- Respirator for Enclosed Spaces: If you're down in a bilge or tucked away in a small cabin, don't mess around with fumes. They can build up fast. A respirator with the proper acid gas cartridges is an absolute must to keep that corrosive vapor out of your lungs.

Think of your PPE like a life jacket. It might feel like overkill for a quick job, but you’ll be incredibly thankful it’s there if things go sideways. Proper gear is a cornerstone of our boat safety equipment checklist, and it's just as important here as it is out on the water.

Preparing Your Workspace

Alright, once you're suited up, it’s time to protect your boat and the area around it. An acid spill can etch gelcoat, stain teak, or ruin vinyl upholstery in the blink of an eye. A few minutes of prep now will save you from a world of expensive headaches later.

First, get some air moving. If you aren't out in the open, set up a couple of fans to create a good cross-breeze. Point one fan pulling fresh air in and another pushing fumes out and away from you. It’s a simple trick that makes a huge difference in the air you're breathing.

Next, cover up anything and everything you don't want the acid to touch. Thick plastic sheeting and painter's tape are your best friends here.

- Drape any teak decks or trim.

- Shield your vinyl seats and coaming pads.

- Protect any nearby painted or polished surfaces.

- Lay sheeting down on the dock or ground under where you're working.

The Most Important Prep Step: Neutralization

Here’s a pro tip that too many people skip: have your neutralization solution mixed and ready before you start. If you have a spill or get some acid where it shouldn't be, you won't have time to go hunting for baking soda and water. You need to act fast.

It couldn't be simpler to mix. Just stir up a slurry of baking soda and fresh water. A good rule of thumb is about one cup of baking soda to a gallon of water. Keep that bucket, along with a dedicated sponge or rag, right by your side the entire time you're working. This one little step turns safety from an afterthought into an active part of your process, keeping you in complete control.

Applying Acid Removers on Different Surfaces

Alright, you've got your workspace prepped and your safety gear on, so it's time for the main event. Successfully using an acid to get rid of rust isn't about just splashing it on and hoping for the best. It's a bit of an art, and the process changes completely depending on what you're trying to clean. A method that works wonders on a stainless steel stanchion could easily dull or even damage a gelcoat finish.

Before you even think about applying an acid remover, you have to know your material. Taking a moment to understand different metal types and their characteristics can be the difference between a great result and a costly mistake. This little bit of homework ensures you're helping, not hurting, your boat's finish.

What we're really doing here is starting a targeted chemical reaction. Acids like phosphoric, hydrochloric, and citric acid go after rust by chemically changing the iron oxides into compounds that can be easily rinsed away.

Phosphoric acid, in particular, is the heavy hitter here; it's what you'll find in most commercial rust removers because it's so good at converting rust into a stable iron phosphate. It's no surprise that acid-based products hold a massive 54.45% of the rust remover market—they simply work.

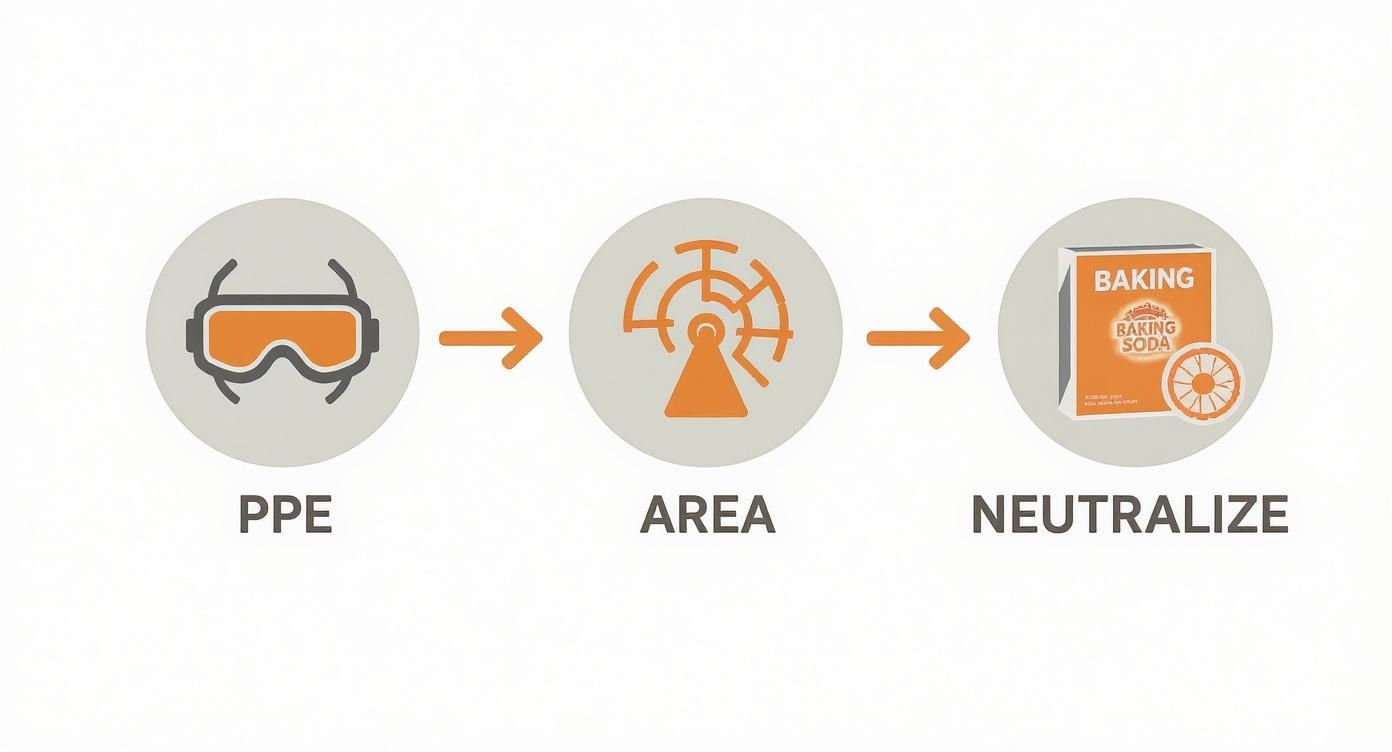

This quick visual is a great reminder of the safety flow: PPE, ventilation, and having your neutralizer ready before you start.

Think of it less like a single step and more like a series of checks that create a safe, controlled environment for the job.

Treating Stainless Steel Railings and Hardware

Stainless steel is the workhorse on any boat, but let's be clear: it's rust-resistant, not rust-proof. When you see rust on railings, cleats, or stanchions, it's usually from surface contamination or a breakdown in the steel's protective layer. Our goal is to get rid of the rust without scratching that polished finish.

For jobs like this, a gel-based acid remover is your best friend. Unlike watery liquids that just run off, a good gel formula clings to vertical or curved surfaces, letting the acid do its job right where you need it.

Application and Dwell Time

Using a small, soft-bristle brush, apply the gel directly onto the rust stains. You'll want to gently agitate the area for about 30 seconds to work the product in. This isn't about hard scrubbing; you're just making sure the gel makes full contact with the rust.

Now, let it sit for 5 to 15 minutes. Keep an eye on it. You'll often see the rust start to change color or look like it's dissolving—that's how you know it's working. Just don't let the gel dry out completely.

Restoring Gelcoat and Fiberglass Surfaces

There are few things more annoying than seeing those ugly orange weep stains running down from a screw or cleat onto your beautiful white gelcoat. Gelcoat is porous and surprisingly sensitive. Using an acid that's too strong or leaving it on too long can permanently etch or dull the finish.

For gelcoat, a milder oxalic acid-based formula is almost always the safest and most effective choice. These products are less "hot" than their phosphoric acid cousins and are fantastic at lifting metallic stains out of the gelcoat's pores.

Products like our Instant Hull Cleaner are specifically designed for this purpose, using a buffered oxalic acid formula to dissolve rust stains without damaging the underlying surface.

Key Steps for Gelcoat

- Clean First: Always wash the area with regular boat soap and water. This gets rid of any surface dirt and lets the acid get right to the stain.

- Apply Sparingly: Use a sponge or a cloth to dab the rust remover only on the stained area. Don't slather it all over a big patch of clean gelcoat.

- Watch the Clock: Dwell time is everything here. Start with just 2-3 minutes, then rinse it off completely. If the stain is still there, you can reapply, but never let it sit for long periods.

A huge mistake is treating gelcoat like it's solid metal. For gelcoat, your mantra should be "less is more." Use the mildest product that works for the shortest time possible to preserve that high-gloss shine.

Working with Painted and Coated Surfaces

Applying acid to a painted surface is where things get really tricky. The acid has no idea you only want it to eat the rust; it will happily attack the metallic pigments or primers in your paint, too. The risk of discoloring or stripping the paint is very real, so you have to be extremely careful.

The absolute, non-negotiable first step is to spot-test in a hidden area. Find a place under a rail, inside a locker, or on the back of a part where a small blemish won't be seen. Apply a tiny drop of your diluted acid solution and watch how the paint reacts for a few minutes.

Techniques for Painted Areas

- Dilute Your Solution: Start with a 50/50 mix of your rust remover and water to knock its strength down.

- Use a Q-Tip: For tiny rust spots, a cotton swab gives you pinpoint precision, helping you avoid contact with the good paint around it.

- Immediate Neutralization: The second you see the rust dissolve, hit it with your baking soda slurry. You need to stop that chemical reaction instantly before it has a chance to damage the paint.

A Special Note on Aluminum

While you won't see the same red rust on aluminum as you do on steel, it can still corrode, forming a chalky white oxide. Using a strong acid on aluminum is generally a bad idea because it can cause pitting and ugly discoloration.

For aluminum, a specialized cleaner is a much safer bet. We actually have a whole guide dedicated to this. You can learn more about how to clean aluminum pontoons in our article.

By tailoring your approach to each specific surface, you can get rid of rust without causing collateral damage. It all comes down to respecting the material and the chemical you're using.

The All-Important Neutralizing and Rinsing Stage

You’ve watched the acid work its magic, dissolving the rust right before your eyes. The surface looks brand new. It's incredibly tempting to wipe it down and call it a day, but this next step is where a good repair becomes a great one—or where it all goes wrong.

Removing the rust is only half the job. The neutralizing and rinsing process is arguably the most critical part of getting a lasting fix. Leaving even a microscopic trace of acid on the metal is like setting a ticking time bomb for future corrosion.

It will continue to eat at the surface, often causing a new, more aggressive bloom of rust to appear almost overnight. This is why proper neutralization isn't just a friendly tip; it's a non-negotiable part of the process.

Why You Can't Skip Neutralization

Think of the acid as "active" until you specifically tell it to stop. Just wiping it off or giving it a quick spray with a hose won't cut it. Any leftover acidic molecules will pull moisture right out of the air and immediately start corroding the fresh, vulnerable metal you just worked so hard to expose.

This is a big deal, especially when you consider how many powerful acid-based products are out there. The global rust remover market was valued at around USD 613.34 million and is expected to hit USD 794.04 million by 2030. Acid-based formulas dominate that market for one simple reason: they work. But that effectiveness comes with a responsibility to finish the job correctly. If you're interested in the numbers, you can explore the full rust remover market report.

The biggest mistake I see people make is assuming a quick water rinse is enough. Water only dilutes the acid; it doesn't neutralize its pH. You have to chemically halt the reaction with an alkaline solution. Otherwise, your hard work could be undone in a matter of hours.

Mixing and Applying a Neutralizing Slurry

Fortunately, the best neutralizing agent is probably already in your kitchen pantry: baking soda (sodium bicarbonate). Mixing up a simple slurry of baking soda and water creates an alkaline solution that will instantly shut down any leftover acid on contact.

Here’s my go-to formula:

- The Mix: Stir about one cup of baking soda into one gallon of fresh, warm water until it's mostly dissolved.

- Application: Grab a dedicated sponge or a spray bottle and apply the solution liberally over the entire area you treated with acid. Don't be shy here—you want to completely soak the surface.

- Look for the Fizz: As you apply the slurry, you might see some light fizzing or bubbling. That's a good sign! It means the baking soda is actively neutralizing the residual acid.

Keep applying the mixture until all the fizzing stops. That’s your visual cue that the surface is no longer acidic. Let the solution sit for a minute or two before you move on to the final rinse.

The Final Rinse and Dry—No Shortcuts!

With the acid neutralized, the last job is to wash everything away and get the surface bone-dry immediately. If you don't, you risk "flash rust," a thin layer of surface corrosion that can form on freshly exposed steel or iron within minutes if it's left wet.

Rinsing the Right Way

Volume is your friend here. Use plenty of fresh water to flush the surface completely. A garden hose with a gentle spray nozzle is perfect for this.

- Work from the top down. Let gravity do the work for you. This carries all the neutralized acid and baking soda residue away without leaving streaks on areas you've already cleaned.

- Flush out all the tight spots. Make sure water flows into every nook, cranny, and seam to wash out any trapped solution.

Drying is a Race Against Time

Whatever you do, don't let the metal air-dry. You need to get it completely dry as fast as you possibly can.

- Wipe It Down: Start with a clean, dry microfiber towel to soak up the bulk of the water.

- Blast It with Air: Follow up with compressed air. I use a leaf blower or an air compressor with a nozzle to blast water out of bolt holes, seams, and other spots where it loves to hide.

- Add a Little Heat (Optional): For really critical parts, a heat gun on a low setting can help evaporate any final traces of moisture. Just be careful not to scorch any painted or sensitive surfaces.

By following this meticulous process, you guarantee your rust removal job will actually last. You've stopped the corrosion, cleaned the slate, and prepped a perfectly stable surface that’s ready for its protective topcoat.

Protecting Surfaces to Prevent Future Rust

You did the hard part—the rust is gone. The surface is clean, neutralized, and dry. But don't pop the top on a cold one just yet. This next step is what separates a quick fix from a long-term solution, making sure all that effort wasn't for nothing.

Once you use acid to remove rust, the surface is left perfectly clean but also totally exposed. That fresh metal or bare gelcoat is a sitting duck for the same saltwater and sun that caused the rust in the first place. Without a protective barrier, you'll be right back where you started in no time.

Sealing Stainless Steel and Other Metals

When you treat stainless steel, the acid strips away not just the rust but also the thin, passive oxide layer that gives it its corrosion resistance. Your job now is to put that protection back.

The best way to do that is with a high-quality metal polish or wax. A dedicated Marine Metal Polish isn't just about making things shiny. It gets down into the microscopic pores and imperfections on the metal's surface, creating a hydrophobic barrier that sheds water, salt spray, and other corrosive gunk.

- Creates a Sacrificial Layer: The wax coating takes the abuse from the elements, shielding the actual metal underneath.

- Blocks Oxygen and Moisture: It seals the surface, cutting off the two key ingredients rust needs to form.

- Restores Brilliant Shine: It buffs out any minor dullness left over from the acid cleaning, bringing your hardware back to a mirror finish.

For aluminum parts you've treated, grab a specialized corrosion inhibitor spray. These products are specifically designed to stop that chalky white oxidation that plagues aluminum in the marine world.

Fortifying Gelcoat and Painted Surfaces

Gelcoat is naturally porous, which is why rust stains can look like they've soaked right in. After an acid treatment, those pores are clean but they're also wide open, just waiting for the next stain.

Applying a fresh coat of marine wax is the perfect way to seal things up. A good Fiberglass Polish & Wax doesn't just restore that deep, glossy look; it lays down a slick, protective film over the gelcoat. This makes future cleanups a breeze because new dirt and grime will just wipe off instead of sinking in.

Think of it like waxing your car. You're not just doing it for the shine; you're protecting the paint from sun, bird droppings, and road grime. It's the exact same idea for your boat's gelcoat—a solid coat of wax is its best line of defense.

To really nail this, it helps to know what you're buying. For a full breakdown, check out our guide on the differences between marine wax and polish in our guide. It’ll help you pick the right product for a perfect, lasting finish.

Establishing a Maintenance Routine

Protection isn’t a one-and-done job. The real secret to keeping a boat rust-free is to make it part of your normal routine.

- Inspect Regularly: After you get back to the dock, do a quick walk-around. Pay special attention to your hardware and any spots where you know rust likes to pop up.

- Rinse Thoroughly: A simple freshwater rinse-down after every trip, especially in saltwater, is probably the single most effective thing you can do to prevent rust.

- Reapply Protection: Depending on how much you use your boat and where you keep it, plan on reapplying your metal and fiberglass wax every 3-4 months.

By taking a little time now to protect those freshly cleaned surfaces, you break the endless cycle of rust and repair. This is the final step that keeps your boat looking sharp and protects its value for years to come.

Common Questions About Marine Rust Removal

Even with the best game plan, you're bound to have some questions pop up when you start working with acids to remove rust. Getting the right answers is the key to doing the job safely and getting a finish that actually lasts. Let's tackle some of the most common things we hear from fellow boat owners.

What Is the Safest Acid for My Boat's Gelcoat?

When you're dealing with a sensitive surface like gelcoat, you always want to reach for the mildest acid that will get the job done. That's almost always an oxalic acid-based cleaner.

Our Instant Hull Cleaner is a great example, using a buffered oxalic acid that’s tough on rust stains but gentle on fiberglass. These formulas are far less aggressive than something like phosphoric acid, so they're much less likely to dull or etch that delicate finish.

Before you go all-in, always do a little spot test in a place no one will see. It's a simple step that saves a ton of headaches, confirming the product won't cause any weird discoloration. And pay close attention to the recommended application times on the label—letting it sit too long is the number one reason people run into trouble.

Can I Just Use Household Vinegar on Stainless Steel?

It's tempting to grab something cheap from the galley, but plain old vinegar (acetic acid) just doesn't have the muscle for serious marine rust. It might make a dent in a brand-new, light rust spot, but it needs to stay on the surface for a very long time, which just isn't practical for railings and hardware.

You'll save yourself a lot of time and effort by using a purpose-built marine rust remover with phosphoric acid. It gets to work in minutes, not hours, chemically converting the iron oxide into a compound that just rinses away. The job is faster, and the results are way more thorough.

What Happens If I Forget to Neutralize the Acid?

Forgetting to neutralize the acid is probably the biggest mistake you can make. Any acid you leave behind will keep eating away at the surface, even after you've rinsed, creating an even bigger mess than what you started with.

On metal, leftover acid will cause immediate "flash rust" and can even lead to pitting, which permanently weakens the material. On gelcoat, it can cause ugly yellowing and break down the surface integrity. Always, always follow up your acid treatment with a baking soda slurry and a complete freshwater rinse.

How Should I Dispose of Leftover Acid Solution?

Proper disposal isn't just a good idea—it's critical for protecting our waterways. Never, ever pour leftover acid directly into the water or down a storm drain, even if you've diluted it.

First, you need to completely neutralize the solution. Slowly add baking soda to your leftover mix until it completely stops fizzing. Once it’s neutralized, you’ll need to check your local marina and city regulations for their specific disposal rules. In many places, a pH-balanced solution can be safely flushed down a sanitary sewer with lots of fresh water.

At Better Boat, we know keeping your vessel looking its best is a top priority. For a powerful, yet surface-safe solution to rust stains, our Instant Hull Cleaner is specifically formulated to handle tough marine corrosion on fiberglass and painted surfaces without heavy scrubbing.