DIY Gelcoat Repair for Boats a Flawless Finish Guide

Fixing up your boat's gelcoat can feel like a big job, but trust me, it’s one of the most important things you can do to protect your investment. This isn't just about making your boat look good at the dock; it’s about defending its fiberglass hull from water intrusion and UV rays. Getting a handle on this process is a skill every boat owner should have in their back pocket.

Why Gelcoat Repair Is More Than Just a Cosmetic Fix

That glossy finish on your boat? It’s not just for show. Your gelcoat is the first and most important line of defense for the fiberglass structure underneath. When you spot a chip, a deep gouge, or those annoying spider cracks, you're looking at a breach in its armor.

It’s tempting to ignore these little flaws, but that's a gamble you don't want to take. Water has a way of finding any weak spot. Once it gets past the gelcoat, it starts to soak into the fiberglass laminate, and that's when the real trouble begins.

A Smart Investment in Your Boat's Future

Think of gelcoat repair for boats as a core part of your maintenance routine, not just a chore to get to eventually. Every small fix you make is a direct investment in your boat’s health, longevity, and of course, its appearance.

The marine industry knows this well. It accounts for a massive 39.7% of the entire gelcoat market, which hit USD 1.38 billion in 2023. That number tells you just how critical this protective layer is, especially in environments with constant saltwater and sun exposure.

The best part? You don't need to be a pro to get a professional-looking, nearly invisible repair. With the right materials, a bit of patience, and a step-by-step approach, you can restore your boat's protective finish and keep it looking fantastic. For a full walkthrough, check out our complete guide on boat gelcoat repair.

Common Gelcoat Damage and What It Means

Not all gelcoat damage is created equal. I've put together this quick table to help you identify what you're looking at and figure out the best way to tackle it.

| Type of Damage | What It Looks Like | Recommended Action |

|---|---|---|

| Crazing / Spider Cracks | Fine, web-like cracks, often in areas of high stress or flex. | Usually cosmetic. Widen the cracks slightly with a Dremel, fill with gelcoat paste, and then sand and polish. |

| Chips & Gouges | Small to medium-sized chunks of gelcoat missing, often from impacts. | Clean the area, bevel the edges of the damage, fill with a color-matched gelcoat paste, and then finish. |

| Deep Scratches | Scratches that go through the gelcoat and may expose the fiberglass below. | Similar to a gouge repair. Clean, fill with gelcoat paste, build it up in layers if needed, then sand and polish. |

| Blisters | Bubbles or pimples on the surface, indicating water intrusion (osmosis). | A more serious issue. Requires grinding out the blisters, drying the area thoroughly, and applying an epoxy barrier coat. |

| Oxidation / Fading | A dull, chalky appearance caused by UV exposure. | Can often be restored with a good rubbing compound and polish. If severe, wet sanding may be needed first. |

Understanding what you're dealing with is the first step. Once you've identified the problem, you can confidently grab the right tools and materials to get your boat's finish back to its former glory.

Building Your Essential Gelcoat Repair Toolkit

Trying to tackle a gelcoat repair for your boat without the right stuff is a recipe for disaster. It’s like navigating without a compass—you’ll end up somewhere, but probably not where you intended. Putting together a solid toolkit isn’t just some preliminary step; it’s the absolute foundation for a repair that blends in perfectly.

Having everything you need right at your fingertips saves you from those frustrating mid-job runs to the marine store. More importantly, it means you won’t be tempted to cut corners on quality.

Your kit will shift a bit depending on what you’re fixing, whether it’s a web of fine spider cracks or a deep, nasty gouge. That said, a core set of supplies will get you through 90% of the gelcoat problems you're likely to encounter. The goal is to build a kit that lets you work smart and get a finish that looks like a pro did it.

This focus on maintaining a boat's finish is a big deal. The global market for pleasure boat gelcoat was pegged at around USD 500 million back in 2025 and is only expected to climb. That growth is all about boat owners like us who know that a healthy gelcoat is crucial to protecting our investment. You can dig into the market trends and tech behind this on Data Insights Market.

Core Repair Materials

First up, let's talk about the products that will actually become the new surface of your boat. These are the non-negotiables, and getting the right ones makes all the difference.

- Gelcoat Paste: To fill in chips, cracks, and dings, you need a thick paste, not a runny resin. It's specifically made to stay put and not sag down a vertical surface.

- MEKP Catalyst: This is the magic liquid—Methyl Ethyl Ketone Peroxide—that kicks off the hardening process in your polyester-based gelcoat. Always, always follow the manufacturer's ratio. Too little and it won't cure; too much and it'll cure too fast and crack.

- Color-Matching Tints: Let's be real, unless your boat just rolled out of the factory, the color has faded a bit. A small tinting kit with the basic colors (black, white, red, yellow, blue) is your secret weapon for nailing that perfect match to your sun-aged gelcoat.

- Acetone: This is your go-to for surface prep. It cuts through wax, grease, and any other gunk that would stop the new gelcoat from getting a death grip on the old surface.

Essential Tools for Preparation and Application

Once you've got your materials, you need the right tools to prep the damage and lay down the paste. I’ve learned over the years that a few key tools are the difference between an ugly patch and an invisible repair.

One of my absolute must-haves is a rotary tool (like a Dremel) with a small V-shaped or conical grinding bit. This thing is a game-changer for spider cracks. It lets you chase the crack precisely, carving out a little V-groove that gives the new gelcoat paste way more surface area to bite into. The result is a much, much stronger bond.

A classic rookie mistake is just smearing paste over a hairline crack. That creates a weak, superficial patch that’s almost guaranteed to crack again. Taking the time to properly grind out the damage is what separates a quick fix from a permanent repair.

Here are the other tools you’ll want within arm's reach:

- Mixing Sticks and Cups: Don't eyeball it. Clean, disposable containers are a must for mixing your gelcoat and catalyst accurately.

- Plastic Putty Knives/Spreaders: Flexible plastic spreaders are ideal for working the paste into the repair and building it up slightly proud of the surface.

- Blue Painter’s Tape: Use this to mask off the area right around the damage. It keeps the surrounding gelcoat clean and gives you a crisp edge to work against.

Understanding Waxed vs. Non-Waxed Gelcoat

This is a critical detail that trips up a lot of people. Standard polyester gelcoat needs to be shielded from oxygen to cure fully; otherwise, the surface stays tacky forever. To get around this, you have two options: use a "waxed" gelcoat or add a wax additive yourself.

As the gelcoat cures, the wax floats to the top, creating a barrier against the air and allowing it to get rock-hard. For most small DIY jobs, just buying a gelcoat paste that already has the wax additive included is by far the easiest route.

Another option for non-waxed gelcoat is to cover the repair with a bit of plastic film or a spray-on PVA (Polyvinyl Alcohol) mold release agent to block the oxygen.

It's also important to know that gelcoat isn't the same as other repair materials. While epoxy is an absolute beast for structural repairs thanks to its incredible strength, it's not what you want for the final cosmetic coat. You can get the full scoop on when to use different resins in our ultimate guide to choosing epoxy resin for your boat.

With these items in your toolkit, you're not just patching a problem anymore—you're ready to restore your boat's finish with real confidence and precision.

Mastering Surface Prep for a Lasting Bond

The real secret to a gelcoat repair for boats that you can't even spot has less to do with the paste and more to do with what happens beforehand. I'm talking about the prep work. It's the meticulous, almost surgical process that makes sure the new material fuses with the old, creating an unbreakable bond.

Think about trying to paint on a greasy surface. It doesn't matter how premium the paint is; it’s going to peel. Gelcoat is no different. Every last trace of wax, grime, or oil has to go. Honestly, skipping this is the number one reason I see DIY repairs fail after just one season on the water.

Cleaning and Dewaxing the Area

First up, you need to give the area a serious cleaning. Don't just give it a quick wipe. You're chemically stripping away years of contaminants. I always start with a decent marine-grade soap and some water to get the loose dirt and salt off.

Once it's bone dry, it's time for the most critical part: dewaxing. This is where you'll need some acetone. Grab a couple of clean, lint-free rags and wipe down an area several inches larger than the actual damage.

The trick is to use a "two-rag" method. One rag gets soaked with acetone to dissolve the wax, and a second, clean, dry rag follows right behind it to lift the dissolved wax off completely. Just using one rag tends to smear the contamination around.

The whole point is to get back to the original, raw gelcoat. When it's properly prepped, the surface will look dull, almost chalky. If you see any shine at all, there's still wax on there. Keep at it with the acetone until that gloss is gone.

Opening and Shaping the Damage

Now that the surface is clean, it's time to deal with the damage itself. Just slapping filler into a sharp-edged chip or a tight crack is a recipe for failure. New gelcoat needs a wide, angled surface to really bite into. Think of it as creating a mechanical "key" for the repair to lock into.

For gouges and chips, I'll grab a rotary tool fitted with a countersink bit or a small V-shaped grinding stone. The idea is to grind the edges of the damage down into a gentle, tapered bevel, almost like a shallow crater. This chamfered edge drastically increases the surface area for the paste to bond to, making for a much stronger fix.

If you're dealing with spider cracks, you have to chase them out. Using that same V-shaped bit, carefully grind along each crack, turning it from a hairline fracture into a shallow groove. I know it feels wrong to make the damage look bigger, but it's the only way to get the new gelcoat deep enough to stop the crack from coming back.

After all that grinding, give the area one last, meticulous wipe-down with acetone to get rid of every spec of dust. This is your final chance to get the surface perfectly clean.

Masking for a Clean Repair

The last step before you mix any paste is masking. Get some high-quality painter's tape and carefully outline the repair area. A simple square of tape works for a small chip. For longer scratches, run tape along both sides.

This does two important things:

- It protects the good gelcoat around the repair from accidental smears, which are a real hassle to clean up later.

- It gives you a crisp edge to work with, which makes the sanding and finishing stages so much easier.

I usually tape just a little bit beyond the beveled edge. This lets me slightly overfill the repair—a crucial technique we'll get into next—without making a huge mess. Once you've cleaned, beveled, and masked the spot, you've done the hardest part. This careful prep is what separates a quick patch from a permanent, professional-quality gelcoat repair for boats that will stand the test of time.

Applying Gelcoat Paste Like a Pro

With all the prep work done and dusted, you’re on to the fun part: making that damage disappear for good. This stage is all about transforming the gouge into a smooth, invisible repair. To really pull this off, you need to focus on two things: getting the color spot-on and mixing the paste correctly.

Color matching is more of an art than a science, especially if your hull has soaked up a few seasons of sun. That "factory white" from the container rarely matches the five-year-old, sun-kissed white on your boat.

This is where a good tinting kit becomes your best friend. Start with a base color that's pretty close, and then add tiny drops of pigment to a small test batch until you've nailed the perfect shade.

Nailing the Perfect Color Match

An invisible repair lives or dies by the color match. Rushing this step is a rookie mistake, and a little patience here will pay off in a big way.

- Always use natural light. Mixing and comparing colors under garage fluorescents is a recipe for disaster. Take your materials outside into bright daylight to see the true colors.

- Test your mix and let it cure. Wet gelcoat is a liar. It often darkens just a bit as it hardens. Dab a small amount of your mixture on a clean, out-of-the-way spot on the hull and let it fully cure before you make the final call on the color.

- Start light and add dark sparingly. It's way easier to add a single drop of black or yellow to darken a mix than it is to try and lighten a batch that’s gone too dark.

Getting this right is a familiar task for the thousands of boat owners tackling gelcoat repair for boats every year. They're part of a marine gelcoat market valued between USD 1.5 to 2 billion as of 2025. With projected growth of 5-7% annually through 2033, and hull applications leading the charge, quality repairs are more important than ever. You can find more industry details in the marine gelcoat market report on archivemarketresearch.com.

Mixing Gelcoat Paste with Catalyst

Once you’re happy with the color, it’s time to bring the gelcoat to life by mixing in the hardener, or catalyst—usually Methyl Ethyl Ketone Peroxide (MEKP). This kicks off a chemical reaction that generates heat as it cures. Getting the ratio right is absolutely critical.

The most common mistake I see is people adding "a little extra" catalyst to speed up the process. Don't do it. Too much MEKP will make the cured gelcoat brittle and prone to cracking down the road. Too little, and it might never fully harden. Stick to the manufacturer's instructions, which is almost always 1-2% catalyst by volume.

Your "pot life" is the amount of working time you have from the moment you mix until the gelcoat starts to thicken up. Temperature is the biggest factor here. On a cool, 65°F day, you might get a leisurely 15-20 minutes. But on a hot 85°F day, that window can shrink to less than 10 minutes. Only mix as much as you can comfortably apply in that time.

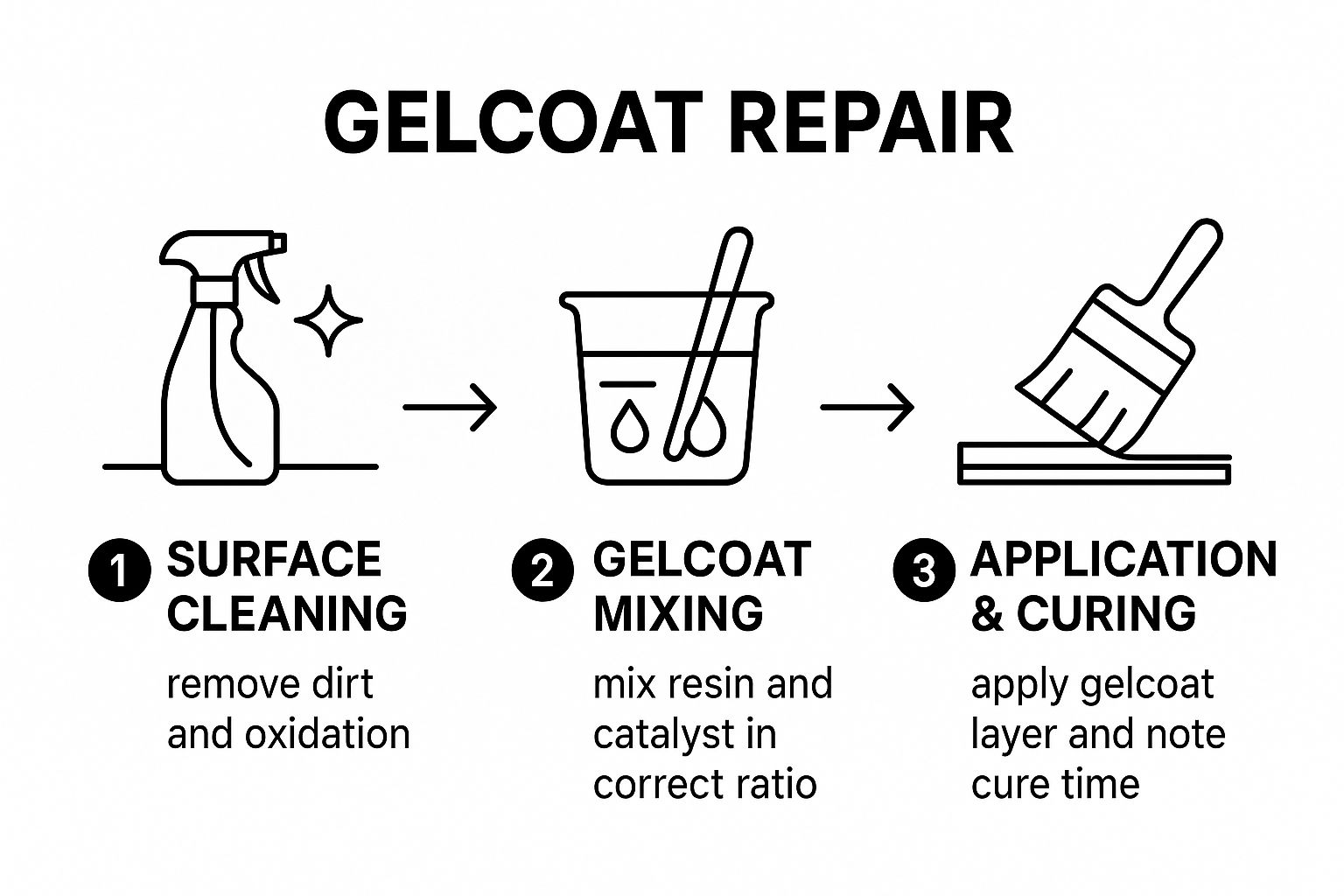

This workflow shows how a professional finish is built one step at a time. Each stage, from prep to application, lays the foundation for the next.

Applying the Paste and Ensuring a Proper Cure

Grab a flexible plastic spreader and start working the mixed paste into the prepped damage. You want to press it in firmly to squeeze out any trapped air bubbles. Air pockets create weak spots that can cause the repair to fail later on.

Here's a pro tip: slightly overfill the repair. You want the paste to sit just a little proud of the surrounding surface. Gelcoat shrinks a tiny bit as it cures, and this extra material ensures you can sand it down perfectly flush instead of ending up with a slight dip.

Now, about the cure. Standard gelcoat won't harden properly if it's exposed to air; the surface will stay tacky forever. You have to seal it off.

There are two main ways to do this:

- Use a Wax Additive: The easiest route is to buy "waxed" gelcoat or mix a surfacing wax agent into your paste. As the gelcoat cures, the wax floats to the top and forms a barrier against oxygen.

- Cover the Repair: If you’re using a non-waxed gelcoat, you have to cover it. You can spray on a layer of Polyvinyl Alcohol (PVA), which creates an air-tight film. For smaller jobs, you can just tape a smooth piece of plastic wrap or a cut-up sandwich bag tightly over the wet paste.

Once it's applied and sealed, just leave it alone. Fight the urge to poke it to see if it's hard yet. Depending on the temperature, it'll be ready to sand in a few hours, but a full cure can take up to 24 hours. You'll know it's ready when you can tap it with your fingernail and hear a sharp "click."

Finishing and Polishing for an Invisible Repair

This is where all that careful prep work really pays off. Right now, you’ve got a cured gelcoat patch, but it’s a dull, rough spot on an otherwise gleaming hull. This final stage is what will transform that patch and make it completely disappear. It’s a process of pure refinement, taking the repair from a leveled surface to a mirror shine until you can’t even tell where the damage was.

We're not just trying to make it shiny; the goal is to blend it so perfectly that the memory of the original damage fades away. This is the step that separates a decent patch-up from a truly professional gelcoat repair for boats.

The Art of Leveling with Wet Sanding

First things first, you need to knock down that slightly overfilled repair until it’s perfectly flush with the surrounding gelcoat. Dry sanding is way too aggressive for this—it builds up too much heat and leaves deep, ugly scratches.

Wet sanding is what the pros do. The water acts as a lubricant, carrying away the sanding dust so the paper doesn't clog. It’s the secret to a much, much smoother finish.

Grab a firm sanding block for this. If you use a flexible one or just your fingers, you’re guaranteed to create a wavy, uneven surface. Wrap a sheet of 320-grit waterproof sandpaper around the block, dip it in a bucket of clean water, and get to work on the cured patch.

Use light, even pressure and a cross-hatch pattern. Sand in one direction, then switch to a 90-degree angle to that first direction. This little technique ensures you’re leveling the surface uniformly, not just creating grooves. Keep the whole area wet and rinse your sandpaper in the bucket often. You’ll actually feel the resistance get lighter as the high spot of the repair comes down.

Stop the second the patch feels level with the rest of the gelcoat. You only want to flatten the repair itself, not dig into the original finish around it. Once it's flush, you're ready to start refining.

Progressing Through the Grits

Now, the focus shifts. You’re no longer leveling—you’re removing the sanding scratches you just made. The only way to do this right is by working your way up through progressively finer grits of sandpaper. Each finer grit erases the scratches left by the previous one.

It’s a methodical process, but it’s the absolute key to a flawless shine.

- 600-Grit Sandpaper: Switch over to 600-grit wet/dry paper. Keep wet sanding the area, making sure you remove every visible scratch from the 320-grit paper. You'll start to see a hazy, semi-gloss sheen develop.

- 800-Grit Sandpaper: Now, move up to 800-grit. Continue wet sanding until the surface is uniform and the finer scratches from the 600-grit are totally gone.

- 1000 to 1200-Grit Sandpaper: This is your final sanding step. An ultra-fine grit like 1000 or 1200 will leave the surface feeling incredibly smooth to the touch, with a dull but even luster. At this point, all visible sanding marks should be gone.

After that final pass with the sandpaper, clean the area thoroughly and let it dry completely. You need a spotless surface for the next stage, because any leftover sanding residue will get into your polishing pads and mess up the finish.

Keeping your boat clean in general makes spotting new damage much easier. You can learn more about how to clean a fiberglass boat in our detailed guide: https://betterboat.com/blogs/news/how-to-clean-fiberglass-boat

Bringing Back the Shine with Compound and Polish

With the surface perfectly smooth, it's time to bring back that deep, factory gloss. This is a classic two-step process using a power buffer and two different liquid abrasives: a cutting compound, followed by a fine finishing polish.

Start with a rubbing or cutting compound. This is a more aggressive liquid abrasive designed specifically to remove the very fine scratches left by your 1200-grit sandpaper. Apply a small amount to a wool or firm foam cutting pad on your buffer. Work in a small section, about two-foot by two-foot, moving the buffer slowly and steadily. Don't press hard—let the compound do the work.

Once you’ve buffed the entire repair with the compound, wipe the hazy residue off with a clean microfiber cloth. The gloss should be dramatically better, but it will probably still look a little hazy or have some swirl marks.

That brings us to the final touch: a fine finishing polish. This product has much smaller, gentler abrasives that will remove the swirl marks from the compound and produce that crystal-clear, "wet look" shine. Switch to a soft foam finishing pad, apply the polish, and buff the area again until the surface is absolutely dazzling.

Wipe away the last of the residue, step back, and take it all in. The damage is gone. In its place is a strong, glossy finish that blends seamlessly. This is the ultimate reward for a well-executed gelcoat repair for boats.

Common Questions About Gelcoat Repair for Boats

Even with the clearest instructions, you're bound to run into a few head-scratchers during a gelcoat repair. It happens to all of us. Here are some of the most common questions I hear from fellow boaters, along with some straight-up answers to get you through those tricky spots and help you sidestep those all-too-common mistakes.

Can I Apply New Gelcoat Over Old Paint or Wax?

Let me be crystal clear on this one: absolutely no. This is probably the most critical part of the entire process. Gelcoat needs a direct, chemical bond to the fiberglass or the properly prepped gelcoat underneath. It simply will not stick to paint, wax, sealants, or any other gunk on the surface.

If you try to take a shortcut here, the repair is doomed from the start. It might look good for a week or two, but it will peel and delaminate. The new patch will lift right off because it never actually bonded to the hull. You've got to start by chemically stripping any wax with acetone, then sand the area down to a clean, raw surface. That’s the only way the new gelcoat will grab hold for good.

You'll hear old-timers say it all the time because it's true: Preparation is 90% of the job. A perfectly applied repair will fail on a poorly prepped surface. Every single time.

Why Is My Gelcoat Repair Still Sticky After Curing?

Ah, the dreaded sticky finish. If you’ve run into this, don’t worry—it’s a classic rookie mistake and the fix is simple. A tacky surface is almost always the result of the gelcoat being exposed to oxygen while it cures. Standard polyester gelcoat is "air-inhibited," which is a technical way of saying it won't harden completely if air can get to it.

To get that rock-solid, sandable finish, you have to block the oxygen. You've got two main ways to do that:

- Use Waxed Gelcoat: This is the easy button for most DIY jobs. The gelcoat paste comes pre-mixed with a wax additive. As the gelcoat cures, that wax rises to the surface and forms a protective film, sealing out the air.

- Cover the Repair: If you're working with a non-waxed gelcoat, you have to create your own barrier. You can spray it with a PVA (Polyvinyl Alcohol) release film, or you can go low-tech and just tape a smooth piece of plastic wrap tightly over the fresh patch.

Should I Use Gelcoat Paste or Liquid Gelcoat Resin?

For pretty much any cosmetic repair you'll be doing—fixing chips, deep scratches, spider cracks, and gouges—you need gelcoat paste. The name says it all. It’s got a thick, putty-like consistency that’s made to fill voids and stay put without sagging, even when you're working on the side of the hull.

Liquid gelcoat resin is a different animal altogether. It’s much thinner, almost like paint. Its main job is for spraying huge surfaces in a professional shop, like when a boat is being built inside a mold. Trying to fill a deep gouge with liquid resin would be a runny, frustrating mess. Stick with the paste for your repair kit.

How Do I Get a Perfect Color Match for My Boat?

Getting the color spot-on is more art than science, especially on an older hull that’s seen its share of sun. You'll need patience and a good eye. Start by getting a gelcoat color that's as close as you can find to your boat's original shade. Then, you'll need a good tinting kit with your primary pigments (black, yellow, red, blue).

The key is to work in very small test batches. Mix up a tiny amount and add minuscule drops of pigment to nudge the color where you want it. Dab a little bit on a clean, hidden spot on the hull and—this is important—let it fully cure before you judge the match.

Wet gelcoat looks very different from cured gelcoat. And a final pro-tip: it's always easier to make a light color darker, so go easy on the dark pigments. You can't take them out once they're in!

Ready to tackle your next boat project with confidence? At Better Boat, we have all the premium supplies you need for a professional-grade gelcoat repair. Explore our full range of products at https://www.betterboat.com and get your boat looking its best.