DIY Stringer Repair Boat Guide

Finding a stringer problem early is your best bet for a repair that doesn't spiral out of control. When you finally feel that unmistakable soft spot on the deck, the damage underneath is usually pretty far gone. The real trick is learning to spot the subtle warning signs before they turn into a full-blown structural crisis.

Diagnosing Bad Stringers Before You Cut

Before you even dream of picking up a saw, your most important job is to play detective. Tearing up a boat’s deck is a major commitment, and you have to be absolutely sure the stringers are the real problem. A proper inspection is way more than just walking around; it’s about using your senses and a few key tools to map out the extent of the rot.

Think of this as gathering evidence. You’re looking for any and all clues that point to water intrusion. Rushing this part can lead you to cut open a perfectly good section of the boat or, even worse, miss a rotten area that will compromise your entire repair down the road.

Sounding Out the Hull

One of the oldest and most reliable tricks in the book is "sounding" or tapping the hull and deck. Grab a phenolic hammer or even just the plastic handle of a big screwdriver. Start tapping systematically along the stringer lines inside the bilge and then move to the deck above.

You're listening for a distinct change in the sound:

- A sharp, solid "rap" is good news. It means the fiberglass is still tightly bonded to the core. That's the sound of a healthy, solid structure.

- A dull, hollow "thud" is the sound you don't want to hear. This is a dead giveaway for delamination, where the fiberglass has pulled away from the core, or the core itself has turned to mush.

As you find these dead spots, mark them with a grease pencil or some painter's tape. You’ll quickly start to build a visual map of the suspected rot, giving you a much better picture of how big this project is going to be.

Reading the Cracks

The gelcoat on your boat can tell you a lot if you know how to read it. While some light crazing is just cosmetic, certain cracks are clear signs of the boat flexing in ways it shouldn't be.

Keep an eye out for spider cracks radiating out from where the deck is fastened to the stringers. You'll also see them around high-stress spots like seat mounts or the console base. These cracks are screaming that the stringers aren't providing firm support anymore, letting the deck flex every time weight is put on it.

Our guide to repairing a boat hull also covers how to identify different types of fiberglass damage that hint at bigger structural issues.

Expert Tip: Pay special attention to the corners where stringers meet the transom or bulkheads. These joints are the first places stress cracks appear when rot starts to weaken the structure.

Confirming with a Moisture Meter

Tapping and looking for cracks gets you in the ballpark, but a moisture meter gives you the hard data you need to be certain. This is the final piece of evidence before you decide to make the cut.

Use a pinless meter and take readings all along the stringer grid. If you see consistently high readings—anything over 15-20%—it confirms water has gotten past the fiberglass and soaked the core. At that point, rot is practically guaranteed. This little tool helps you know for sure if you're dealing with a small, isolated leak or widespread saturation that means a full-on stringer replacement is in your future.

Proper maintenance is a huge part of the boating world. Even with a small dip, the global boat repair market was projected to hit a massive $8.58 billion by 2023. You can dig into the trends in the global boat repairing market to see just how critical good upkeep is in this growing industry.

Equipping Your Workshop for the Job

Let's get one thing straight: a serious stringer repair boat project is won or lost before you ever make the first cut. Your success hinges entirely on having the right tools, materials, and safety gear ready to go. Think of this as your mission briefing—getting everything lined up now saves you from those frustrating mid-project runs to the store and ensures the job gets done right.

Trust me, walking into a job this big unprepared is a recipe for a headache. You don't want to be halfway through grinding out old fiberglass only to find your last flap disc is shot, or worse, start mixing epoxy without the right gloves. So, let’s go over what you'll need to pull this off like a pro.

Demolition and Prep Tools

The first phase is all about demolition, and it’s a delicate dance between brute force and surgical precision. You need tools that can chew through old, stubborn fiberglass and pry out rotten wood without gouging the hull you’re trying to save.

Your core demo kit should include:

- Angle Grinder: This is your workhorse. A good 4.5-inch model with a coarse flap disc will make quick work of old fiberglass tabbing and prep the hull surface for fresh glass.

- Oscillating Multi-Tool: For the delicate parts of the job, this is your MVP. It’s perfect for clean, controlled cuts in tight corners or when you need to separate the deck from the hull without overcutting.

- Circular Saw (with a depth gauge): Absolutely essential for cutting out large, straight sections of the deck. Setting that depth gauge correctly is the key to avoiding a catastrophic cut into the hull below.

- Pry Bars and Chisels: Simple but effective. Once the fiberglass is cut, you'll need these to get some leverage and peel the soggy, rotten stringer core away from its fiberglass shell.

Outfitting a workshop for major jobs like this can get expensive. If you’re looking to scale up or go professional, it’s worth exploring options for financing specialized workshop equipment.

Core Materials and Resins: Building It Back Better

With all the rotten stuff gone, it’s time to choose the materials to build it back—and this is your chance to make it stronger than it ever was from the factory. The two big decisions are what to use for the stringer core and which resin system will bond everything together.

For the core, your main options are marine-grade plywood or a modern composite foam. Plywood is the traditional, battle-tested choice, known for its incredible strength. The catch? It must be completely encapsulated in epoxy to prevent future rot.

High-density foam, on the other hand, is 100% waterproof and rot-proof right out of the box, though it often requires a bit more fiberglass to achieve the same stiffness as wood.

The resin is the glue that holds your entire repair together. While the manufacturer probably used cheaper polyester resin, our Marine Epoxy Resin Kit is the only way to go for a repair. It provides far superior strength, adhesion, and water resistance, creating a bulletproof secondary bond to the old polyester hull.

Don’t forget about the fiberglass cloth itself. For tabbing the new stringers to the hull, 1708 biaxial cloth is the undisputed industry standard. Its unique weave gives you incredible strength in multiple directions, which is exactly what you need at those critical joints.

To make things easier, here's a comprehensive checklist of the gear you'll need, broken down by phase.

Essential Gear for Your Stringer Repair Project

| Category | Essential Items | Expert Tip |

|---|---|---|

| Demolition & Prep | Angle Grinder, Oscillating Multi-Tool, Circular Saw, Pry Bars, Chisels, Shop-Vac | Use a flap disc on your grinder, not a grinding wheel. It's less aggressive and gives you a better surface for bonding. |

| Core & Lamination | Marine Plywood or High-Density Foam, Better Boat Marine Epoxy Resin Kit, Fiberglass Cloth (1708 Biaxial), Fillers (Cab-O-Sil/Colloidal Silica), Acetone | Mix your epoxy in small batches. It has a limited working time ("pot life"), and mixing too much at once is a recipe for wasted material. |

| Tools & Supplies | Mixing Cups, Stir Sticks, Plastic Squeegees, Chip Brushes, Scissors, Measuring Tape, Utility Knife, Digital Scale | A cheap digital kitchen scale is your best friend for getting perfect epoxy mix ratios every single time. Don't eyeball it! |

| Safety Gear (PPE) | Respirator (with organic vapor cartridges), P100 Particulate Filters, Full-Seal Goggles, Chemical-Resistant Nitrile Gloves, Disposable Coveralls | Have separate cartridges for grinding (particulate) and laminating (vapor). Swapping them out ensures you're always protected. |

Having these items on hand before you start will make the entire process smoother and safer.

Non-Negotiable Safety Gear

I can't stress this enough: working with fiberglass and epoxy means dealing with nasty dust and chemical fumes. Cutting corners on Personal Protective Equipment (PPE) is a terrible idea. Your health is on the line.

Here’s your absolute minimum safety list:

- Respirator: Get a half-mask respirator and fit it with organic vapor cartridges for when you're working with epoxy. For grinding fiberglass, swap those out for P100 particulate filters. Don't breathe that dust.

- Eye Protection: Full-seal goggles are the best way to keep fine dust and resin splashes out of your eyes. At a bare minimum, wear safety glasses.

- Gloves: You'll want two types. Some heavy-duty work gloves for demolition, and a big box of chemical-resistant nitrile gloves for handling and mixing epoxy.

- Protective Clothing: Disposable coveralls might seem like overkill, but they'll save your skin from itchy fiberglass dust and sticky resin. It makes cleanup a whole lot easier, too.

Tearing It Down: The Demolition Phase

Okay, you've diagnosed the problem and gathered your supplies. Now it's time to roll up your sleeves and get to work. This is the demolition phase, and I’ll be honest, it feels a lot more like boat surgery than just smashing things up.

The name of the game is precision—you want to get every last bit of rotted material out while leaving the healthy parts of your hull untouched.

This is usually the part of a stringer repair boat project that makes people the most nervous, but it's completely doable if you take your time. We're going to walk through how to open up the deck, carefully remove the bad stringers, and get the hull perfectly prepped for its new backbone. A methodical approach right now is what sets you up for a repair that’s even stronger than when it left the factory.

Gaining Access: Cutting the Deck

Your first big move is cutting open the deck or sole to get to the stringer grid. The key here is to make your cuts as clean and straight as possible. This will make glassing it all back together much easier down the road.

Grab a circular saw and set the blade depth to just a hair more than the thickness of the deck. Cutting too deep is a classic mistake. If you slice into the hull below, you've just created a much bigger repair job for yourself.

Before you cut, map it all out with a pencil and a straight edge. I always try to follow existing lines on the boat or create symmetrical openings that won't look out of place when the job is done.

For those tight corners where the circular saw can't quite reach, an oscillating multi-tool is your best friend. It’ll let you finish the cuts neatly without overcutting and weakening the surrounding deck.

The Surgical Removal of Rotten Stringers

With the deck opened up, you'll come face-to-face with the rotten stringers. They’re almost always encased in a fiberglass shell. Your mission is to carefully cut away this outer skin to get at the soggy, pulpy wood core inside.

An angle grinder with a flap disc is the right tool for this job. Use it to grind through the fiberglass "tabbing" that holds the stringer to the hull, and then cut along the top of the stringer. Go slow and let the grinder do the work—the goal is to peel away the old fiberglass without gouging the hull itself.

Once the fiberglass shell is open, you can start digging out the rotted wood. This is messy work. You’ll be using pry bars, chisels, and a good shop vac. Sometimes the wood comes out in wet, mushy chunks; other times it’s more like a pile of damp sawdust.

Crucial Tip: No matter how rotten it is, try to remove the old stringer core in the largest pieces you can manage. These soggy bits are the perfect templates. Lay them out on a sheet of plastic to dry, and they’ll give you the exact shape you need for the new stringers. This one tip can save you hours of tricky measuring.

This kind of structural job is a big part of the larger boat repair and maintenance market. That global market was valued at a massive USD 15.5 billion in 2023 and is only expected to climb. If you're curious, you can explore detailed insights into the boat maintenance market to see the trends driving these figures.

Prepping the Hull for a New Bond

After all the old stringer material is gone, you're left with an empty cavity in the hull. This next part is arguably the most critical step of the entire demolition process. The strength of your new stringers depends completely on getting a solid mechanical bond between the new fiberglass and the old hull. A smooth, dirty surface just won't work.

You have to grind away every last trace of old resin, paint, and gunk from the areas where the new stringers will sit. This means grinding the hull bottom and up the sides where the new tabbing will extend.

- Target Surface: You're aiming for a fresh, raw fiberglass surface that looks dull and feels slightly rough.

- Grinding Tools: Stick with your angle grinder, but switch to an 80-grit flap disc. It’s aggressive enough to clean the surface quickly but won't leave it too chewed up for a good bond.

- Safety First: This part creates an unbelievable amount of fine, itchy fiberglass dust. A full-face respirator with P100 filters, disposable coveralls, and gloves are non-negotiable. Don't even think about skipping this.

Once the grinding is done, the final prep is a deep clean. Vacuum every single speck of dust out of the bilge. Then, wipe down all the ground surfaces with a clean rag soaked in acetone. This gets rid of any oils, waxes, or leftover dust that could ruin your epoxy's bond. The hull is now a clean slate, ready for its new structure.

Fabricating and Installing Your New Stringers

Alright, you've survived the demolition phase. The old, rotten junk is gone, and you’ve got a clean hull prepped and ready for a new backbone. This is where the real fun begins. You get to stop tearing things apart and start building. This is your chance to make the boat’s structure even better than it was when it rolled out of the factory.

This isn't just a simple replacement job; it's a serious upgrade. We're going to walk through turning your templates into new stringers, bedding them perfectly into the hull, and then wrapping them in a tough-as-nails shell of fiberglass and epoxy. Honestly, this is the most satisfying part of the whole project.

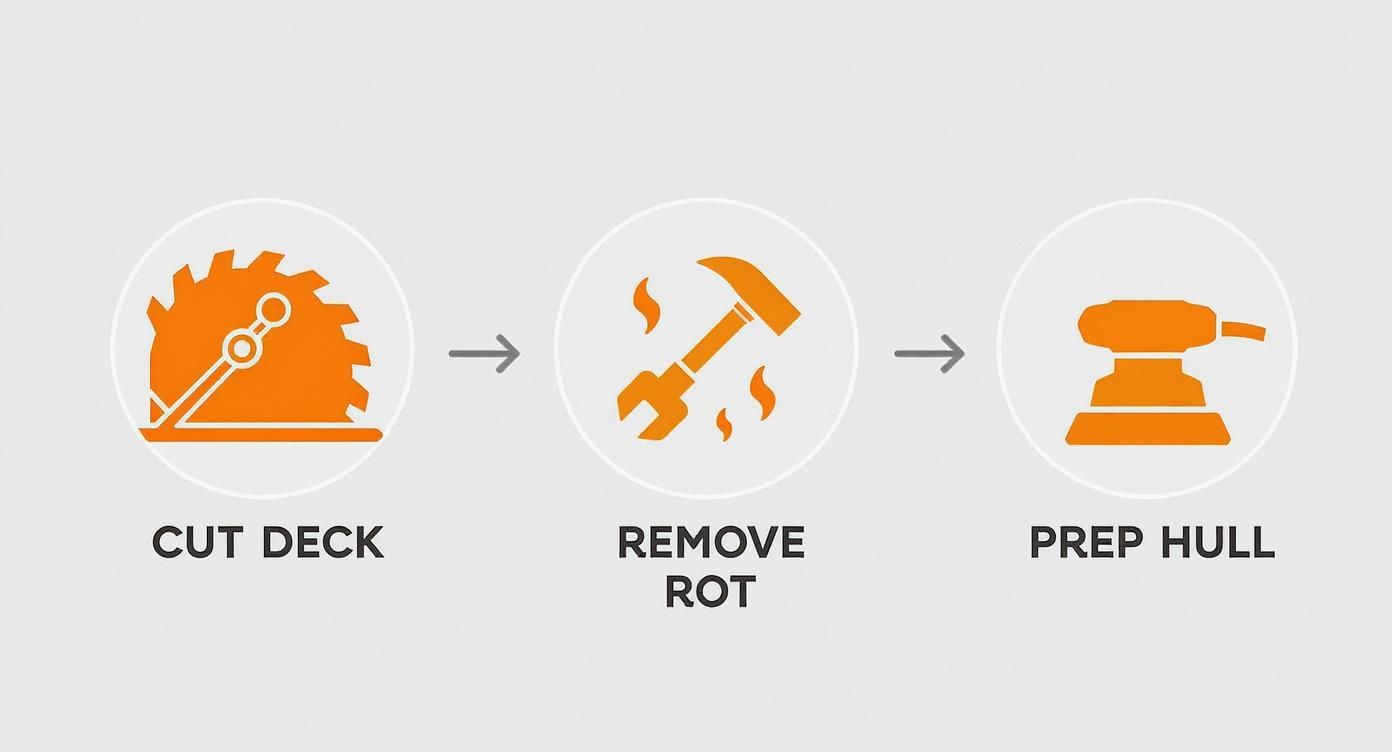

The image below gives you a quick visual recap of that messy demo process, from cutting the deck to getting the hull ready for what comes next.

Think of it this way: a bulletproof installation is only possible after meticulous demo and prep work. Now, let's build.

Transferring Templates and Making the Cuts

First up, you need to turn those dried-out pieces of the old stringer core into perfect patterns. Grab your new material—whether that's marine-grade plywood or a high-density composite foam—and lay the old pieces on top. Carefully trace their outlines, paying extra attention to the original angles and curves where they met the hull.

With everything traced, it's time to make some sawdust (or foam dust). A jigsaw is your best friend for tackling the curves, while a circular saw will give you those nice, straight top edges.

- For Plywood: Once your new stringers are cut, do yourself a favor and pre-coat every single side with a thin layer of our unthickened Marine Epoxy Resin. This completely seals the wood, making it waterproof. Think of it as a permanent insurance policy against future rot.

- For Foam Core: Foam doesn't need sealing, but be gentle with it. It's incredibly strong once it's glassed in, but the raw foam can get dented or chipped pretty easily before installation.

Now, "dry fit" your new stringers inside the hull. They should sit right where they belong without any huge gaps. Don't sweat minor variations; we'll handle those in the next step.

The Critical Art of Bedding Your Stringers

You can't just drop the stringers in and start throwing fiberglass at them. To get a rock-solid bond and spread the load evenly across the hull, you have to "bed" them in a thick epoxy putty. This crucial step fills every little imperfection between the stringer and the hull, guaranteeing 100% contact.

To make this bedding compound, mix up a batch of our Marine Epoxy Resin and thicken it with a structural filler like colloidal silica. You're aiming for a consistency like thick peanut butter—it shouldn't run or sag at all.

Slather a generous bead of this epoxy putty along the hull right where the stringer will sit. Then, press the new stringer down into it firmly. You should see the putty squish out along both sides, which is exactly what you want. Use a mixing stick or your gloved finger to smooth that excess into a nice, rounded fillet.

This fillet is way more than just a neat-looking joint; it's a structural powerhouse. A smooth fillet lets the fiberglass cloth lay down without any sharp bends, which prevents air bubbles and creates a massively stronger bond between the stringer and the hull.

The Lamination and Layup Schedule

With the stringers bedded and the fillets cured, it's time to give them their real strength by laminating them with fiberglass cloth. This is what builds a structure that will outlast the rest of the boat. Knowing your way around epoxy is critical here. For a deep dive, check out our complete guide on using epoxy resin for boat repair.

Your "layup schedule" is just the plan for what type and how many layers of fiberglass you'll use. A popular and very effective schedule involves alternating different types of cloth.

- First Layer (Mat): Some folks start with a layer of chopped strand mat to build bulk and help the glass conform to the fillets. It's a common practice, but not absolutely necessary when you're using epoxy.

- Structural Layers (Biaxial Fabric): The real muscle comes from 1708 biaxial cloth. This stuff has fibers running in two different directions, giving it incredible strength. You’ll want to lay down at least two to three layers of this on each side of the stringer.

- Finishing Layer (Woven Roving or Cloth): A final layer of a lighter woven cloth can give you a smoother finish, but it’s not always structurally required.

When you cut your fiberglass, make sure it’s wide enough to run from the hull, up the side of the stringer, and over the top. Always overlap each piece by at least a couple of inches.

Mix your epoxy in small batches you can use quickly, wet out the cloth until it's totally transparent, and use a plastic squeegee to push out any extra resin and air bubbles. This methodical layering is what builds the powerful, solid structure your boat needs to pound through the waves for years to come.

Mastering Safety and Long-Term Prevention

You’ve poured a ton of time and sweat into rebuilding the backbone of your boat. That’s the hard part. Now, let's make sure that hard work lasts a lifetime and that you stay safe while finishing the job.

Working with marine-grade epoxies, resins, and power tools isn't something to take lightly. This is about protecting yourself now and protecting your boat for decades to come.

Personal Protection Is Non-Negotiable

The hazards involved in a stringer repair boat project are no joke. We're talking about fiberglass dust, potent epoxy fumes, and powerful grinders that demand respect. Cutting corners on safety is a fast track to serious, long-term health problems. Don't do it.

Your Personal Protective Equipment (PPE) is your best friend here. The fumes from epoxy resin are loaded with volatile organic compounds (VOCs) that your lungs will hate. Fiberglass dust is even worse—it's an irritant you absolutely want to keep off your skin and out of your body.

Your essential safety gear should include:

- A Quality Respirator: Get one with organic vapor cartridges for resin work and P100 particulate filters for grinding and sanding. No exceptions.

- Full-Coverage Eye Protection: I'm talking about full-seal goggles. They're the only way to keep fine dust and chemical splashes out of your eyes.

- Chemical-Resistant Gloves: Forget standard latex gloves; they won't hold up. You need thick nitrile gloves whenever you're handling epoxy.

Good ventilation and the right PPE create a safe work zone. This lets you focus on the quality of your repair without putting your health on the line.

A Checklist for Long-Term Prevention

Once the repair is done, your mission changes: you're now on water patrol. Your new stringers are sealed up tight, but the rest of the boat needs that same level of defense against water intrusion.

Start by going over every single piece of hardware on the deck and hull—cleats, railings, seat mounts, everything. Take each one off, scrape away the old gunk, and re-bed it with a fresh, high-quality marine sealant like our Marine Sealant & Adhesive Caulk. This is where most water finds its way in, and it's an easy fix.

Next, get a visual on all your limber holes. These little channels at the base of the stringers are designed to let water drain to the bilge pump. If they get clogged with leaves, dirt, or other junk, water gets trapped. Trapped water is the enemy, and it will find a way to cause damage.

Water is relentless. The secret to a repair that lasts is to hunt down and eliminate every possible path for moisture to get into your boat's structure. You want the hull and deck to be a single, sealed unit.

Finally, get obsessive about gelcoat care. Those little spider cracks might look harmless, but they're gateways for water to seep in and soak the core material over time. Fix them as soon as you see them. For a quick and permanent fix, use a fiberglass and gelcoat repair kit, which is perfect for sealing those cracks for good.

The ship and boat repair industry is a testament to how crucial good maintenance is. The market was valued at around USD 36.42 billion in 2024 and is only expected to climb. Taking care of your investment now means more time on the water and less time—and money—spent in the repair yard.

Answering Your Toughest Stringer Repair Questions

You've put in countless hours cutting, grinding, and laying glass. It's only natural to have a few questions rattling around as you near the finish line. A full stringer repair boat project is a serious commitment, and over the years, we've heard just about every question in the book from fellow DIYers.

Let's clear the air on some of the most common concerns. From the dreaded transom rot to the real-world costs, think of this as your final debrief before you can crack open a cold one and admire your handiwork.

How Do I Know If Rot Has Spread to the Transom?

This is the big one—the question that can keep you up at night. If you’ve found rot in your stringers, it's a very real possibility the transom has been compromised too. Thankfully, the process for checking it is almost identical to how you diagnosed the stringers in the first place.

Start by tapping the transom with a phenolic hammer or the plastic handle of a screwdriver, both from inside the bilge and on the outside of the boat. You're listening for that hollow or dull "thud" that signals a void or mushy core. Pay extra close attention to any penetrations, as these are the usual suspects for water intrusion. Check around:

- Engine mounting bolts

- The drain plug

- Transducer screw holes

Next, check for flex. With the boat sitting on its trailer, try to lift and push down on the lower unit of your outboard or outdrive. If you see the transom skin visibly bending, flexing, or hear any cracking or crunching sounds, that's a five-alarm fire. It means the core has lost its structural integrity. For a final, definitive answer, a moisture meter will tell you exactly what’s going on in there.

Can I Just Patch a Small Bad Spot in a Stringer?

We get it. The temptation to just cut out a small rotten section and patch it is strong. It seems like a huge time-saver, but it's almost always a terrible idea. The number one rule in fiberglass boat repair is that the rot you can see is just the tip of the iceberg.

Water is sneaky and wicks its way through wood grain, meaning the decay often runs much farther than the obviously soft spot.

Chasing rot by patching small sections is a recipe for doing the entire job over again in a year or two. The proper way is to remove the stringer back to the nearest bulkhead or intersecting support. This ensures you've cut out all the compromised material and aren't just putting a band-aid on a bigger problem.

The only time you might consider a small patch is for a tiny, bone-dry spot on an otherwise perfect stringer. But even then, you have to be 100% certain it's completely isolated, which is next to impossible to confirm without major exploratory surgery.

What Is the Realistic Cost and Timeline?

This is the classic "how long is a piece of string?" question. The answer depends heavily on your boat's size and just how bad the damage is.

If you take it to a professional yard, be prepared for a hefty bill. A full stringer and transom job on a mid-sized boat can easily run from $5,000 to over $20,000. The boat could also be in the shop for several weeks or even a few months, depending on how busy they are.

Doing the work yourself completely changes the math. Your costs drop down to materials only: epoxy, fiberglass cloth, core material, and all the consumables like brushes, rollers, and sandpaper.

For a typical 18-22 foot boat, a DIYer can expect to spend somewhere between $1,500 and $3,500 for top-shelf materials. The timeline, of course, is entirely up to you. If you're dedicated and can put in the hours every weekend, you might knock it out in a month or two. A more relaxed pace could easily stretch the project across an entire season. Just be honest with yourself about the commitment before you make that first cut.

Your boat's structural integrity is everything. At Better Boat, we provide the professional-grade marine epoxy, fiberglass, and sealants you need to ensure your repair is stronger than the original factory job. Trust our tested products to protect your investment for decades to come. Explore our complete line of boat repair and maintenance supplies and get the job done right.