Finding the Best Marine Vinyl Protectant for Your Boat

Your boat's vinyl upholstery is constantly under assault from harsh UV rays, corrosive saltwater, and persistent moisture. The best marine vinyl protectant is one that offers robust UV defense, deep conditioning without a greasy finish, and mildew resistance. For a comprehensive solution, our Marine Vinyl Protectant sets a high standard for long-term preservation and care.

Protecting Your Investment In Marine Vinyl

Your boat's upholstery is much more than just a place to sit; it's a huge part of your vessel’s value and overall look. Unlike the furniture sitting safely in your living room, marine vinyl fights a constant battle against the elements—a battle that can cause it to wear out surprisingly fast. Proper care isn't just another cleaning chore; it's essential maintenance.

This relentless exposure means that your boat’s specialized, marine-grade vinyl needs a dedicated protectant. If you don't shield it properly, you're setting yourself up for faded, cracked, and brittle seats that are a real headache (and expense) to repair or replace. A proactive approach is the only way to go.

Key Threats to Your Boat's Vinyl

There are a few key culprits constantly working to break down your vinyl upholstery. Knowing what you're up against makes it clear why a high-quality protectant designed for the marine world is non-negotiable.

- UV Radiation: The sun is public enemy number one. Its ultraviolet rays are the main cause of fading and drying, breaking down the plasticizers that keep vinyl soft and flexible. The end result? Brittleness and cracks.

- Saltwater Corrosion: As saltwater evaporates, it leaves behind abrasive salt crystals that grind away at the vinyl's finish and can even weaken the stitching over time.

- Persistent Moisture: High humidity and constantly damp conditions are the perfect breeding ground for mold and mildew. These can cause deep, ugly stains and compromise the integrity of the material itself.

A premium protectant acts as a barrier, neutralizing these threats before they cause irreversible damage. It’s the difference between vibrant, supple seats and a worn, degraded interior.

The market for vinyl cleaners and protectants, including marine-specific ones, hit USD 1.26 billion in 2024. That growth shows a clear trend: boat owners are prioritizing products that can deliver up to 40% longer vinyl life against UV damage and corrosion. In the marine world, the best protectants can achieve 95% stain resistance—a critical feature since untreated vinyl degrades 50% faster in humid environments.

What to Look For in a Protectant

Choosing the right product is about more than just grabbing the first bottle you see. A top-tier protectant is defined by its ability to offer complete, multi-faceted defense. Before you even think about scrubbing the surface—and you can learn more on that in our guide on how to clean marine vinyl—you need to know what features really count.

When you're shopping around, it's easy to get lost in marketing claims. This table breaks down the non-negotiables—the features a premium protectant absolutely must have to stand a chance against the harsh marine environment.

Essential Features of a Premium Marine Vinyl Protectant

| Essential Feature | Why It's Critical for Marine Use | High-Performance Benchmark |

|---|---|---|

| Robust UV Blockers | Prevents fading, drying, and cracking from sun exposure. | Blocks over 95% of harmful UVA and UVB rays. |

| Mildew Resistance | Inhibits mold and mildew growth in damp conditions. | Contains effective anti-fungal agents for humid climates. |

| Non-Greasy Finish | Ensures seats are not dangerously slippery. | Leaves a clean, dry, satin finish that restores original look. |

| Deep Conditioning | Restores plasticizers to keep vinyl soft and flexible. | Penetrates the material instead of just coating the surface. |

Ultimately, a product that checks all these boxes isn't just cleaning your vinyl; it's actively preserving its life, look, and feel for years to come.

Decoding Protectant Formulas and Ingredients

When you're choosing the best marine vinyl protectant, you've got to look past the flashy marketing claims on the bottle and get down to what's actually inside. The formula is everything—it's what dictates performance, and trust me, not all products are created equal.

A great protectant doesn't just slap a temporary shine on your seats; it gets down to the molecular level to truly nourish and defend your boat's upholstery.

The science behind these formulas is what separates a mediocre, short-lived product from a superior one. Key ingredients like UV inhibitors are basically sunscreen for your vinyl, blocking the harsh solar rays that are notorious for causing fading and cracking.

At the same time, ingredients called plasticizers are crucial for keeping the material soft and flexible, stopping it from getting brittle and sad-looking over time.

The Role of Specific Ingredients

A high-quality protectant is a carefully balanced mix of several active components, each with a very specific job. Once you understand what these ingredients do, you can pick a product that provides genuine, lasting care instead of just a superficial coating.

- UV Inhibitors: These are microscopic workhorses that absorb or reflect ultraviolet radiation. They stop UV rays from penetrating the vinyl and breaking down its chemical structure.

- Plasticizers: These compounds are absolutely essential for keeping vinyl supple. A good protectant replenishes the plasticizers that naturally get baked out by the sun and heat.

- Anti-Mildew Agents: In a damp marine environment, fungal growth is a constant battle. These agents create a surface where mold and mildew spores just can't get a foothold, stopping them before they start.

The focus on these ingredients makes sense when you look at the marine vinyl market itself. It was valued at USD 340.8 million in 2023 and is expected to climb to USD 488.0 million by 2030. That growth is all about advancements in material science, including protectant formulas that make upholstery last longer. For a closer look, you can dig into more data on the marine vinyl market and its trends to see the industry's push for durability.

Water-Based vs Solvent-Based Formulas

One of the biggest differences you'll find in protectant formulas is whether they are water-based or solvent-based. Both are designed to protect, but how they do it—and their long-term effects on your vinyl—are worlds apart.

A solvent-based formula uses petroleum distillates to carry its protective agents. Sure, they can produce a high-gloss shine, but those same solvents can be incredibly harsh. Over time, they can actually dry out the vinyl and speed up the very degradation process you're trying to prevent.

Water-based formulas, on the other hand, use water as the carrier. This approach is much gentler, allowing the conditioning agents to soak into the vinyl's pores without causing any harm.

The result is a more natural, non-greasy finish that nourishes from the inside out. For a deeper dive into choosing safe and effective formulas, check out our complete guide on how to choose the best cleaning products for your boat.

The best marine vinyl protectant will almost always be water-based. This type of formula offers deep conditioning without the risk of long-term damage, ensuring your vinyl stays soft and resilient.

The Problem with Silicone

Another ingredient you absolutely need to watch out for is silicone. A lot of protectants use it to create a quick, shiny finish, but that shine comes at a steep price. Silicone is an oil that just sits on the surface of the vinyl, creating a slippery, greasy layer that can be downright dangerous on boat seats.

Even worse, that oily film acts like a magnet for dust and dirt. Over time, it can also seal the vinyl's pores, which stops it from "breathing" and releasing moisture. That trapped moisture can lead to premature cracking and even cause the vinyl to peel away from its backing.

That's why a silicone-free formula is essential for real, long-term protection. Products like our Marine Vinyl Protectant are specifically designed without it.

Instead of a superficial coating, our formula penetrates deep into the vinyl to restore its natural flexibility and provide lasting UV defense—all without leaving that slick, slippery residue. By choosing a formula free from harmful silicones and solvents, you're not just cleaning your boat; you're investing in the health and longevity of its interior.

Comparing Top Marine Vinyl Protectant Types

Let's be honest, walking down the aisle of marine care products can feel a bit overwhelming. You’re hit with a wall of bottles, all promising to be the ultimate defense for your vinyl. The real secret? There isn't one "best" product for everyone. It’s about finding the right tool for the job.

The key is to understand that different formulas are built for different purposes. It’s all about matching the protectant to your boat, your environment, and how much time you want to spend on maintenance.

We can break down the main players into three groups: All-in-One Cleaner & Protectants, Dedicated UV Blockers, and the more advanced Polymer Coatings. Each has its own strengths, and knowing when to use which will make all the difference in keeping your interior looking sharp.

The Convenient All-In-One Cleaner And Protectant

Think of all-in-one products as the masters of convenience. These formulas are made for boaters who need a quick and easy solution for everyday upkeep. They blend gentle cleaners with some light protective agents, letting you wipe down seats after a day on the water to get rid of salt spray, sunscreen smudges, and minor spills, all while leaving a thin protective film behind.

Their biggest advantage is speed. If you’re a busy boat owner or run charters and need a fast turnaround, an all-in-one is a lifesaver. But that convenience does come with a trade-off. The protective muscle—especially the UV blocking and conditioning—is nowhere near as strong or long-lasting as what you'll find in a dedicated product. It's a great tool for the weekly wipe-down, but it’s not the heavy hitter you need for serious, long-term preservation.

The Powerhouse Dedicated UV Blocker

When your number one enemy is the relentless sun, a dedicated UV blocker is your best friend. These are specialized formulas engineered with a single, critical mission: to provide the toughest defense against the harsh ultraviolet rays that cause vinyl to fade, dry out, and eventually crack.

Products like our Marine Vinyl Protectant fit perfectly in this category. They are packed with a high concentration of powerful UV inhibitors that form a durable shield right on the vinyl's surface. Unlike the all-in-ones, these protectants also have deep conditioning agents that soak into the vinyl to replenish its natural plasticizers, keeping the material soft and supple from the inside out.

A dedicated UV blocker is non-negotiable for any boater whose vessel lives under direct sunlight. Its singular focus on sun defense delivers a level of protection that multi-purpose products just can’t touch.

Using this type of protectant is a two-step dance—you clean first, then you protect. Sure, it takes a bit more effort than a spray-and-wipe all-in-one, but the superior, longer-lasting results are impossible to ignore. It’s the go-to solution for getting your boat ready for the season and for any vessel that’s stored outdoors.

Advanced Polymer and Ceramic Coatings

On the high-performance end of the spectrum, you'll find advanced polymer and ceramic-hybrid coatings. These are a more modern take on surface protection, creating a semi-permanent, microscopic shield over your vinyl. This layer is incredibly hydrophobic (it repels water) and oleophobic (it repels oil), making it unbelievably tough.

The main draw here is durability. A single application can last for months, sometimes an entire season, giving you amazing resistance to stains, chemicals, and UV damage. Water just beads up and rolls right off, taking dirt with it, which makes your regular cleaning a whole lot easier.

While we're focused on vinyl, looking into broader solutions like marine ceramic coatings can give you a good idea of what’s possible for total vessel care.

These coatings aren't without their own quirks, though. The application is much more involved and requires an almost surgically clean surface for the coating to bond correctly.

They also carry a higher price tag. For the die-hard enthusiast or professional detailer looking for maximum longevity, they’re a fantastic choice, but they might be overkill for the average weekend boater.

Head-to-Head Protectant Formula Comparison

To help you see the differences more clearly, here’s a straightforward breakdown of how these protectant types compare on the metrics that matter most.

| Protectant Category | Ideal Use Scenario | UV Protection Rating | Recommended Reapplication | Resulting Finish |

|---|---|---|---|---|

| All-in-One Cleaner & Protectant | Quick, weekly maintenance after use; light-duty cleaning. | Low to Moderate | Every 1-2 weeks | Clean, light sheen |

| Dedicated UV Blocker | Seasonal protection; boats in high-sun areas; deep conditioning. | High to Very High | Every 4-6 weeks | Rich, non-greasy satin |

| Advanced Polymer Coating | Long-term durability; professional detailing; stain prevention. | Very High | Every 6-12 months | Slick, hydrophobic gloss |

So, what’s the final word? The best marine vinyl protectant is the one that fits your routine and your boat’s needs. For most owners who want lasting quality and serious sun defense without a complicated process, a dedicated, water-based formula like our Marine Vinyl Protectant hits that sweet spot. It delivers the powerful UV blocking needed to stop long-term damage while conditioning your vinyl—all without the fuss of advanced coatings.

Proper Application for Maximum Protection

Picking out the best marine vinyl protectant is only half the battle. Even the most premium product on the shelf won’t do its job if you don't apply it correctly. The truth is, your application technique is just as critical as the formula inside the bottle. A little bit of care here ensures you get a flawless, durable finish that stands up to UV rays, salt, and stains all season long.

This guide will walk you through the essential steps, from prep to the final buff. Getting this part right isn’t a chore—it’s one of the most important things you can do to preserve your boat's interior.

Preparing the Surface for Treatment

You wouldn’t wax a dirty car, and the same logic applies here. Applying a protectant over a grimy surface is a waste of time and money. Any dirt, old sunscreen, or mildew will stop the product from bonding to the vinyl, leaving you with a blotchy finish and spotty protection. A perfectly clean surface is non-negotiable.

Start by giving every inch of vinyl a thorough cleaning. For everyday grime, a good marine vinyl cleaner and a soft-bristle brush are all you need. If you’re fighting mildew, you’ll want something that kills it at the root, like our Mildew Stain Remover.

This ensures you’re not just sealing the fungus in under a new protective coat. For a deeper dive into cleaning techniques, check out our guide on how to clean vinyl boat seats.

Once it’s clean, the next critical step is making sure the vinyl is 100% dry. Trapped moisture will mess with how the protectant cures. Grab a clean microfiber towel and wipe everything down, paying extra attention to the seams and stitched areas where water loves to hide. To be safe, let it air-dry for at least an hour in the shade before you move on.

Applying the Protectant Like a Pro

With your vinyl prepped and ready, it's time to apply the protectant. The key is to work smart. Avoid working in direct, hot sunlight, which can make the product flash off too quickly and leave ugly streaks. An overcast day or a spot in the shade is perfect.

Here’s a simple, can't-mess-it-up process for a perfect application:

- Work in Small Sections: Don't try to tackle all the seats at once. Focus on one cushion or one backrest at a time. This gives you plenty of time to work the product in before it starts to dry.

- Apply to Your Applicator: Lightly mist the protectant onto a clean microfiber pad or towel, not directly onto the vinyl itself. This prevents overspray and gives you way more control.

- Wipe with Overlapping Strokes: Gently wipe the protectant onto the vinyl using even, slightly overlapping strokes. Think of it like painting—you want consistent, full coverage.

- Let It Soak In: Give the product a few minutes to sit. This allows the conditioners and UV inhibitors to really penetrate the vinyl’s pores.

- Buff Off the Excess: Using a separate, clean microfiber towel, gently buff the surface to remove any leftover product. This step is what gives you that rich, non-greasy satin finish that isn’t slippery.

Pro Tip: More is not better. It's tempting to lay it on thick, but that just creates a sticky, dust-magnet of a mess. A single thin, even coat is all you need for complete protection.

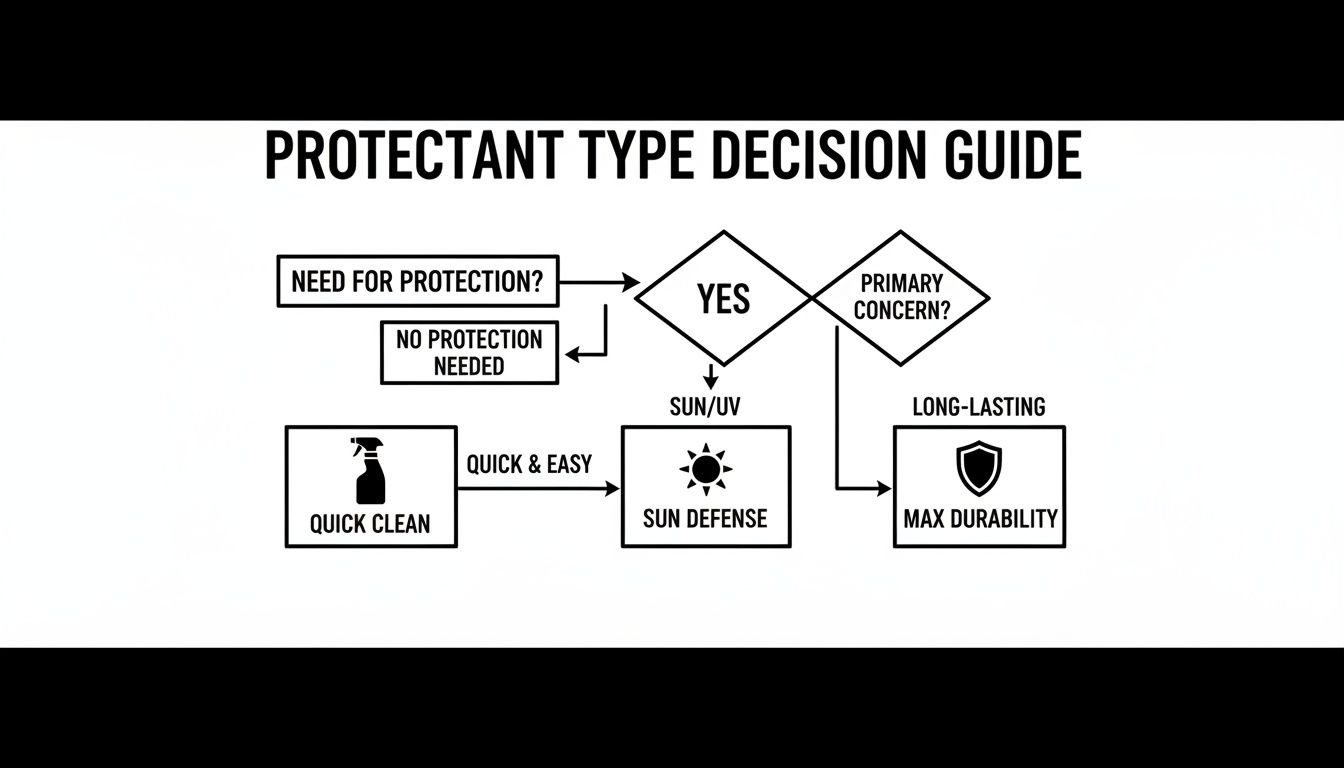

This decision tree helps you visualize which type of protectant makes the most sense for your main goal, whether that's a quick shine-up, serious sun defense, or long-term durability.

As you can see, matching the product to your specific needs is the best way to get the results you're after. It helps you find the right balance of performance and convenience, leading you straight to the most effective solution for your boat.

Maintaining Your Protected Vinyl Long-Term

Protecting your boat's vinyl isn't a one-and-done job; it’s an ongoing commitment. Once you've applied a quality marine vinyl protectant, the real work begins with a simple, consistent maintenance routine. This is what keeps that protective barrier strong, making your initial effort worthwhile and ensuring your interior looks pristine season after season.

Think of the protectant like a shield that takes a beating from the sun, salt, and everything else. To keep that shield up, you need a smart reapplication schedule and a gentle touch for routine cleanings. This kind of proactive care is what stops the gradual breakdown that leads to expensive reupholstery jobs down the road.

Establishing a Reapplication Schedule

How often you reapply protectant isn't about marking a date on the calendar. It’s all about your boat's real-world conditions. A few key factors determine how long a single application will last, and you’ll need to adjust your schedule to get the best defense.

Keep these variables in mind when planning your maintenance:

- Climate and Sun Exposure: A boat baking in the Florida sun is going to need a lot more attention than one tucked under a covered lift in the Pacific Northwest. For those high-sun areas, plan on reapplying every 3-4 weeks. In milder climates, every 5-6 weeks during the season usually does the trick.

- Usage Frequency: If you’re running charters or pulling wakeboarders every day, your vinyl needs more frequent care than a boat that only sees weekend action. Heavy use means more exposure to sunscreen, salt, and general friction, all of which wear down the protective layer faster.

- Storage: A boat cover is your vinyl’s best friend, period. If you’re diligent about covering your boat when it’s not in use, you can often stretch your reapplication interval by several weeks.

A quick trick to check your protective barrier is to spray a little fresh water on the seat. If it beads up into tight little drops, your protectant is still doing its job. If the water starts to spread out or look like it's soaking in, it’s time for a fresh coat.

This need for consistent protection is a big reason why the global marine vinyl market is projected to grow at a 5.6% CAGR through 2033—boaters want durable, UV-resistant materials.

The right protectant can extend the lifespan of marine vinyl by up to 50% in harsh conditions, making it a critical part of boat ownership. For a deeper dive into market trends, you can explore the full research on marine vinyl fabrics.

Best Practices for Routine Cleaning

What you do between applications is just as important as the reapplication itself. Regular wipe-downs are crucial for getting rid of surface grime like salt, dirt, and spills before they can eat away at the protective coating. The goal is to clean your vinyl without accidentally stripping off the barrier you worked so hard to put there.

For these quick clean-ups, stay far away from harsh, all-purpose cleaners. They’re just too aggressive. Instead, reach for a gentle, pH-neutral boat soap or a dedicated marine vinyl cleaner.

These products are formulated to lift dirt without messing with the UV blockers and conditioning agents in your protectant. Honestly, just wiping down the seats with a damp microfiber cloth after each trip can make a massive difference in the long run.

Why Better Boat Is Our Top Recommendation

After testing and comparing what’s out there, one product consistently floated to the top. When you need a marine vinyl protectant that delivers serious defense and deep conditioning, our top pick is our own Marine Vinyl Protectant. It just nails all the key things that experienced boat owners are looking for.

This isn't about one standout feature. It's about the whole package—a formula built to handle the harsh realities of the marine world without cutting corners. It gives you that premium protection, making it a smart investment in your boat's interior.

Superior UV Defense and Conditioning

The number one job of any protectant is to fight off the sun, and this is where our product really delivers. Its formula is packed with powerful UV blockers that create a tough shield against the rays that fade, dry out, and crack your vinyl. Unlike those greasy, silicone-based products that just sit on top, this water-based formula actually soaks into the vinyl's pores.

This approach does two things really well:

- It gets the UV inhibitors deep into the material for protection that actually lasts.

- It restores the essential plasticizers that keep your vinyl soft and flexible, just like it was from the factory.

The end result is vinyl that feels nourished and strong, not just coated. You're actively preventing the brittleness that leads to expensive repairs down the road.

A Formula Built for the Real World

Sun protection is critical, but the practical details are what truly set our protectant apart. It's specifically made to be silicone-free and non-greasy, leaving a clean, satin finish that isn't slippery when wet. That’s a huge safety feature for boat seats, keeping you and your crew planted.

Because it's water-based, it's also gentle on your vinyl and stitching over time. It won't seal up the material's pores or trap moisture underneath, which is a classic way that cheaper protectants end up causing damage.

This thoughtful formula makes it incredibly easy to use. It buffs off without a fight, leaving zero sticky residue behind—just that clean, factory-fresh look.

For boaters who want a product that just works, you can explore the benefits of our marine vinyl protectant and see the quality for yourself. It brings together all the must-haves—UV blocking, deep conditioning, and a safe, clean finish—into one simple solution.

Frequently Asked Questions About Marine Vinyl Care

Even the most seasoned boaters have questions when it comes to caring for their boat's interior. We get it. Getting straight, practical answers is the best way to avoid common mistakes and make sure your hard work pays off. Let's tackle some of the most common questions we hear from boat owners about protecting their vinyl upholstery.

Can I Use an Automotive Vinyl Protectant on My Boat Seats?

That's a hard no. It might seem like a good idea in a pinch, but using automotive products on marine vinyl is a recipe for disaster. Your boat upholstery lives in a completely different world than your car's dashboard—it's getting hammered by intense UV rays, corrosive saltwater, and constant humidity. Car products just aren't built for that kind of abuse.

Marine-specific protectants are loaded with heavy-duty UV inhibitors and powerful mildew-resistant agents that your boat desperately needs. If you use a car product, you'll see your vinyl start to fade, crack, and break down way faster than it should. Always stick with a formula made for the marine environment; it's the only way to get protection you can count on.

How Often Should I Apply Marine Vinyl Protectant?

This really comes down to how much sun and weather your boat sees. There's no single magic number, but here's a good rule of thumb:

- High-Exposure Boats: If your boat is sitting out in the sun in a place like Florida or Arizona, you'll want to reapply a protectant every 3-5 weeks. The sun down there is relentless.

- Moderate-Exposure Boats: For boats kept under a cover or in a milder climate, reapplying every 6-8 weeks during the boating season should do the trick.

A simple way to tell if it's time for a fresh coat is the water bead test. Splash a little water on the vinyl. If it beads up into tight little droplets, you're still protected. If the water spreads out or soaks in, your protective barrier is gone and it's time to reapply. Staying consistent is what really prevents long-term damage.

Will a Vinyl Protectant Make My Seats Slippery?

This is a great question and a totally valid safety concern. Nobody wants their passengers sliding off the seats. The culprit behind that greasy, slippery feeling is usually a cheap, silicone-based product that just sits on top of the vinyl instead of soaking in.

A premium, water-based formula works differently. It's designed to actually penetrate into the vinyl's pores, nourishing the material from the inside out. This keeps it flexible and leaves a clean, non-greasy satin finish that feels natural to the touch. You get all the protection without that slick, dangerous residue.

Choosing the best marine vinyl protectant is about finding a product that gives you both performance and peace of mind, keeping your seats safe and comfortable for everyone on board.

Ready to give your boat's interior the serious protection it needs? Our Marine Vinyl Protectant offers powerful UV defense and deep conditioning without that slippery finish. Shop our Marine Vinyl Protectant today and keep your upholstery looking new for years to come.