Fiberglass Boat Repairs How To Your Ultimate DIY Guide

Learning how to repair your own fiberglass boat is one of the most valuable skills you can pick up as an owner. It really boils down to a few key stages: sizing up the damage, grinding out the bad stuff, layering in new fiberglass cloth and resin, and then finishing the job with fairing compound and gelcoat.

It takes some patience, but with the right gear, most owners can absolutely handle the common dings and cracks that pop up. Doing so saves a ton of money and keeps your boat looking sharp.

Why You Can and Should Repair Your Own Fiberglass Boat

Before you even think about cracking open a can of resin, it’s worth appreciating why tackling your own fiberglass repairs is such a game-changer. Fiberglass is incredibly tough, but let's face it, the marine environment is tougher. Dings from the dock, stress cracks from a rough day on the water, and those other little "oops" moments are just part of owning a boat.

The great thing about fiberglass, though, is how forgiving it is to fix. Unlike a dented aluminum hull or a piece of rotting wood, damaged fiberglass can be completely ground away and rebuilt. You can make it as strong as, or even stronger than, the day it left the factory. This isn't some black magic reserved for the pros; it's a step-by-step process that any dedicated boat owner can get the hang of.

Understanding Common Fiberglass Damage

First things first, you need to know what you're looking at. Most fiberglass damage falls into a few common categories, and figuring out which one you have will dictate your plan of attack.

- Cosmetic Gelcoat Scratches: These are the light scuffs that are only skin deep and haven't touched the actual fiberglass laminate underneath. They're the easiest to fix, usually just needing some gelcoat paste and a good wet sanding session.

- Deep Gouges and Chips: Now we're talking about damage that's gone through the gelcoat and into the fiberglass weave. This will require you to grind out the wounded material and build it back up with new cloth and resin.

- Stress Cracks: You'll often see these as a spiderweb of fine lines around high-stress points like cleats, stanchions, or corners of the transom. They're a sign of flexing, and you have to grind them out completely or they'll just keep coming back.

- Delamination and Blisters: This happens when water finds its way between the layers of fiberglass, causing them to separate or form ugly blisters on the hull. This is a more serious issue that needs to be addressed right away to prevent bigger structural problems down the line.

With recreational boating more popular than ever, there are more boats on the water getting their fair share of wear and tear. The global market for fiberglass boats hit about USD 11 billion in 2023 and is only expected to climb. This just goes to show how important it is to know how to maintain your own investment. You can dig into the fiberglass boat market trends to see just how much it's growing.

The Value of a DIY Repair

Getting your hands dirty with these repairs pays off in more ways than one. Sure, you fix the problem, but you also gain a much deeper understanding of how your boat is put together. And, of course, you'll save a huge amount of cash compared to paying professional yard fees.

A well-executed DIY repair not only restores your boat's integrity but also preserves its value. Buyers look for well-maintained vessels, and knowing how to keep your hull flawless is a major advantage.

Ultimately, learning to work with fiberglass gives you a real sense of confidence and self-sufficiency. The next time you hear that sickening crunch against the dock, you won't see it as a disaster. You'll see it as a manageable project you’ve got the skills to handle.

Gathering Your Fiberglass Repair Toolkit

Walking into a marine supply store can feel a bit overwhelming, but trust me, a professional-quality repair all comes down to having the right gear on hand before you start. Knowing what to grab—and just as importantly, why—turns a big, intimidating job into a totally manageable project.

Think of this as your definitive shopping list for any fiberglass boat repair. A good outcome starts with safety, and that part is absolutely non-negotiable. You're going to be working with some serious chemicals and creating fine dust particles, so protecting yourself is always priority one.

Personal Protective Equipment (PPE)

Seriously, don't even think about grinding fiberglass or mixing resin without the proper gear. I've seen people try to cut corners here, and it’s a recipe for a really bad day.

- Respirator with Organic Vapor Cartridges: Fiberglass dust and resin fumes are nasty stuff. A simple paper dust mask won't do the trick; you need a proper respirator to protect your lungs.

- Safety Glasses or Goggles: This one’s a no-brainer. You need to keep flying debris out of your eyes during grinding and protect them from any accidental splashes of chemicals.

- Chemical-Resistant Gloves: Nitrile or latex gloves are your best friends here. They keep resin and solvents off your skin, which can cause some pretty serious irritation.

Once you’re geared up and safe, you can get to the tools that will do the heavy lifting.

Essential Prep and Application Tools

The quality of your prep work is everything. It directly determines how strong and long-lasting your repair will be. These are the tools that will help you create the perfect surface for the new fiberglass to bond to.

An angle grinder with a coarse sanding disc is your best friend for quickly chewing through damaged material and creating that crucial beveled edge. For the finer shaping and smoothing, a random orbital sander is invaluable.

You'll also need a good supply of acetone for wiping down the repair area—this removes every last trace of contaminants before you even think about applying resin.

Pro Tip: Keep a big box of disposable mixing cups, tongue depressors for stirring, and cheap chip brushes on hand. You'll go through them faster than you think, and trying to clean them is a waste of time and acetone.

Core Repair Materials

Alright, this is the heart of your toolkit. Picking the right materials is what separates a temporary patch from a permanent structural fix. The global boat restoration products market was valued at a whopping USD 6.8 billion in 2023, and fiberglass repair materials made up over 35% of that. That just shows how vital these products are for keeping our boats in top shape.

- Resin (Epoxy vs. Polyester): For most DIY repairs, epoxy is the way to go. It’s stronger, more waterproof, and sticks way better to the existing polyester hulls on most boats. If you want to get into the weeds on this, check out our full guide on choosing the right epoxy resin for boat repair.

- Fiberglass Cloth: The type you need really depends on the job. Chopped strand mat is great for building up bulk quickly, but woven cloth gives you superior strength for structural repairs. More often than not, a combination of both is the ideal approach.

- Fillers and Fairing Compounds: After the structural work is done, you'll need a good fairing compound. This is what you'll use to smooth the entire repair area, making it perfectly flush with the surrounding hull before you move on to gelcoat or paint.

Choosing Your Repair Materials

Not sure whether you need a small patch kit or a full gallon of epoxy? Use this guide to select the right resin and fiberglass for any job, from a small scratch to a major structural repair.

| Type of Damage | Recommended Resin | Recommended Fiberglass | Key Considerations |

|---|---|---|---|

| Small Cracks & Gouges | Epoxy Resin | Woven Cloth (6 oz) or Tape | Epoxy offers the strongest bond for small, concentrated repairs. |

| Spider Cracks/Crazing | Gelcoat or Epoxy with Filler | None (unless structural) | Often a cosmetic issue. Address any underlying flex before filling. |

| Impact Damage/Holes | Epoxy Resin | Chopped Strand Mat & Woven Roving | Layer mat for bulk and woven for strength, extending beyond the hole. |

| Structural/Keel Repair | Epoxy Resin | Heavy Biaxial or Woven Roving | Maximum strength is critical. Use multiple layers for reinforcement. |

Remember, the goal is to match the strength of the original laminate. When in doubt, it's always better to overbuild the repair slightly than to make it too weak.

Mastering Damage Assessment and Prep Work

If you ask any seasoned pro, they'll tell you the same thing: a fiberglass repair is only as good as the prep work. This is where the magic happens, and it’s the most critical phase for creating a permanent, invisible bond. Rushing this part is the single biggest mistake you can make.

First things first, you need to play detective. The real damage is almost always bigger than what you see on the surface. What looks like a simple hairline crack could be hiding a much larger area of delamination just beneath.

Finding the Real Damage

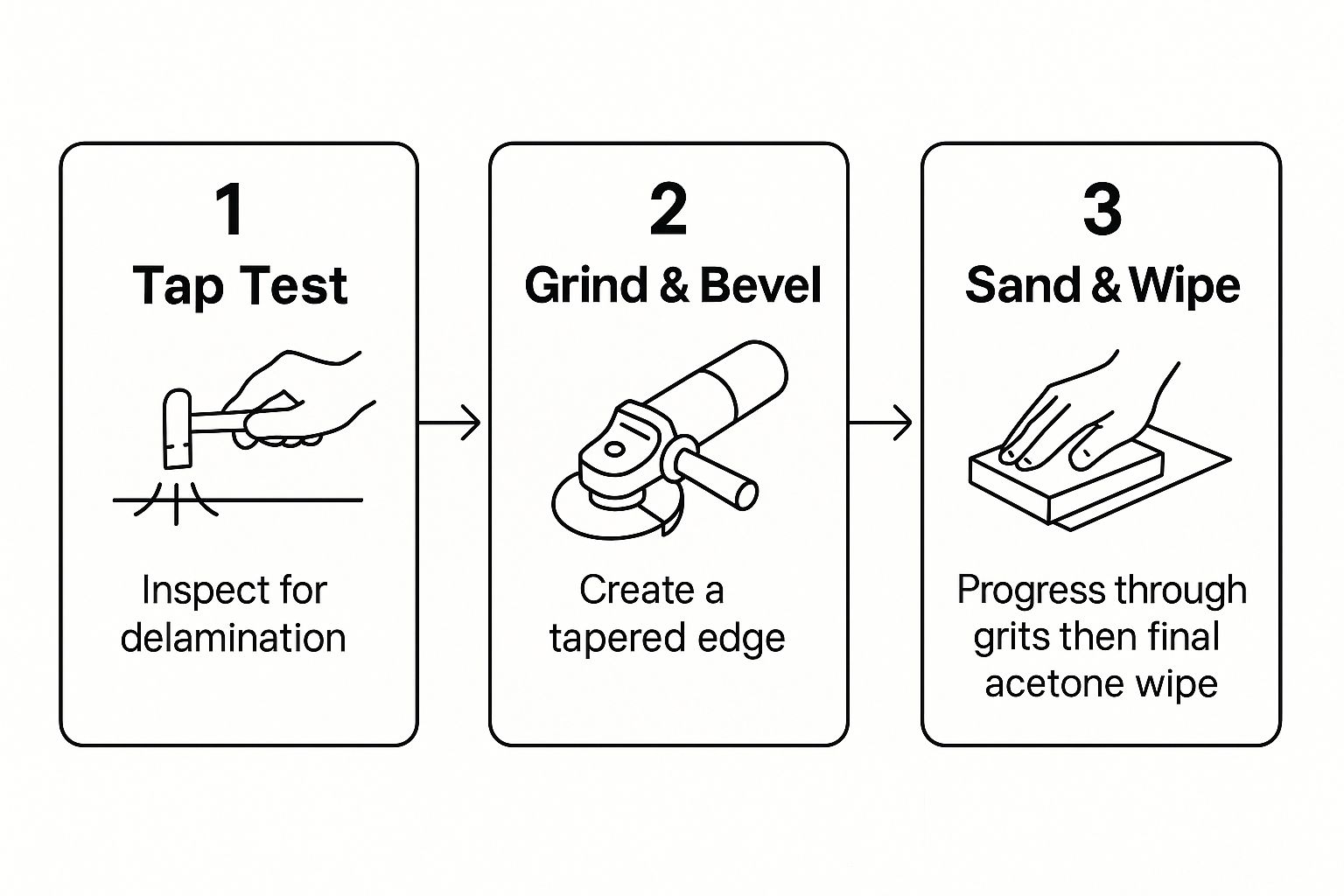

Believe it or not, your best tool for this job is your own ears. The classic "tap test" is a boatyard staple for a reason. Grab a screwdriver with a plastic handle or a small mallet and start lightly tapping the area around the visible damage.

You're listening for a change in sound. A solid, sharp "tick" tells you the fiberglass is sound. A dull, hollow "thud" is the dead giveaway for delamination, which means the fiberglass layers have separated. Take a pencil and mark the entire perimeter of that dull-sounding area. This is your true repair zone.

You absolutely have to grind out all the weakened, delaminated material. Just patching the visible crack is like putting a tiny bandage on a deep wound—it doesn't fix the underlying issue, and you'll be dealing with it again down the road.

This flow chart breaks down the essential prep stages for a fix that will last.

Stick to this sequence, and you'll create a perfectly clean and structurally sound surface that the new fiberglass can really bite into.

Grinding and Beveling for Strength

Once you've mapped out the full repair area, it’s time to fire up the angle grinder. The mission here is to remove every last bit of fractured, water-damaged, and delaminated fiberglass. You're not just cutting out a chunk; you're creating a tapered edge, or a bevel, around the entire perimeter.

That bevel is everything. A straight, vertical edge on your patch creates a butt joint with very little surface area for bonding, making it a serious weak point. A long, gentle taper, however, creates a massive surface for the new fiberglass to bond to, making the repair incredibly strong.

- Grinding Tool: An angle grinder fitted with a 36-grit flap disc works great for this. It chews through damaged material quickly and helps you shape the bevel.

- The 12:1 Rule: For any structural repair, you want a bevel ratio of at least 12:to-1. In plain English, for every 1/8 inch of hull thickness, your taper should extend back 1.5 inches.

- Final Shape: When you're done, the repair area should look like a clean, shallow crater with smooth, gently sloping sides.

Think about the difference between prepping a deep gouge on the keel and dealing with a spiderweb of stress cracks on the deck. That keel repair is going to need a much deeper and wider grind to get its strength back. For the stress cracks, you just need to chase them with a V-shaped groove deep enough to get past the gelcoat and the top layer of laminate.

Final Sanding and Cleaning

With the heavy grinding out of the way, grab a random orbital sander to smooth things out. Start with 80-grit sandpaper and go over the beveled edges and the surrounding area, extending a few inches past your grind marks. This roughs up the surface just enough to create a "tooth" that the new resin can mechanically lock onto.

Now for the final, non-negotiable step: cleaning. Soak a clean, lint-free rag in acetone and wipe down the entire repair area. And I mean wipe it down well—use a fresh side of the rag for each pass to avoid just smearing contaminants around. This gets rid of any dust, oil, wax, or grease that would kill your bond.

Once that's done, your surface is perfectly prepped and ready for fiberglass.

Applying Fiberglass for a Structural Bond

Alright, this is where all that tedious prep work really starts to pay off. You’ve got a perfectly ground, beveled, and clean surface that’s ready for a new lease on life. Applying fiberglass isn't a race; it's a careful, methodical process of rebuilding strength, layer by layer.

Your patience here directly translates into the quality of the finished product. A good repair will be as strong—or even stronger—than the original hull.

The whole thing kicks off with mixing your resin and hardener. This is pure chemistry, and getting the ratio right is absolutely non-negotiable. Always follow the manufacturer's instructions to the letter, whether you're using a handy pre-measured pump system or measuring by volume in a mixing cup.

Mastering the Resin Mix and Pot Life

Once you mix that resin and hardener, the clock is officially ticking. This working window is what we call "pot life," and it’s hugely affected by the weather. On a hot, humid day, your pot life can get cut in half. A cool, dry day, on the other hand, will give you much more time to work.

Here are a few things I've learned to keep in mind:

- Mix Small Batches: Seriously, only mix as much resin as you can confidently use in about 10-15 minutes. This stops the resin from "kicking" (hardening) in your cup before you even get it on the boat.

- Don't Over-Mix: Stir everything together with a mixer, thoroughly but gently for about two minutes. Be sure to scrape the sides and bottom of the cup. If you mix too aggressively, you'll whip air bubbles into it, and those bubbles will weaken the final laminate.

- Spread It Out: A great little trick is to pour your mixed resin out of the cup and into a paint tray. This spreads it thin, slowing down the exothermic (heat-producing) reaction and giving you a bit more working time.

Getting a feel for pot life is one of the core skills you'll develop doing fiberglass repairs. The goal is to work efficiently but never, ever rush. A calm, steady pace ensures you lay down the material correctly without wasting a bunch of expensive resin.

The Wet-Out Technique for Lamination

With your first small batch of resin mixed, you’re ready to start laminating. Let's stick with our example of patching a hole in the hull. You should already have several patches of fiberglass cloth cut, with each piece slightly larger than the last to create a graduated, or "staggered," stack.

First, take your brush and paint a thin, even coat of mixed resin directly onto the beveled repair area. This initial coat is often called a "tack coat," and it just helps that first layer of cloth stick right where you want it.

Next, place your smallest piece of fiberglass cloth into the center of the wet resin. Now, using a brush or a fiberglass roller, apply more resin to the cloth until it becomes totally transparent. This is what we call the "wet-out" technique. A properly wet-out cloth is fully saturated, with no white, dry spots showing. You can dive deeper into the specifics of using these materials in our detailed guide on epoxy fiberglass repair.

Use your brush or a plastic squeegee to gently work out any trapped air bubbles, moving from the center of the patch outwards. These little bubbles are the enemy of a strong repair—they create weak voids in the laminate that you definitely don't want.

Just keep this process going. Add the next-largest patch of cloth and repeat the wet-out procedure. Each new layer should overlap the one before it, building up the thickness and strength of the repair from the inside out.

The quality of materials available today makes this job more effective than ever. For perspective, the global fiberglass market was valued at USD 18.39 billion in 2023 and is projected to keep growing, largely due to ongoing advancements in resin technology. You can see more insights about the fiberglass market's growth on marketresearchfuture.com.

Achieving a Flawless Finish

A structurally sound fiberglass repair is great, but let's be honest, a truly professional job is one that completely disappears. This final stage is all about artistry and attention to detail. It's where you transform that rough patch into a smooth, glossy surface that perfectly matches the rest of the hull. This is where you get that immense satisfaction of a job well done.

Your newly laid fiberglass is strong, but it definitely won't be smooth. The goal now is to shape the repair area until its contours are indistinguishable from the original hull. This process, known as fairing, is where you'll spend a good amount of time with a sander in hand, but the results are worth it.

Shaping with Fairing Compound

First things first, you'll need to apply a high-quality marine fairing compound over the entire repair area. Our Epoxy Resin with Fairing Filler is perfect for this. Mix the filler into the epoxy until it reaches a nice peanut-butter-like consistency.

Using a wide plastic squeegee, spread it on, applying firm pressure to fill any minor pinholes or low spots in the fiberglass laminate. The key here is to apply thin coats rather than one thick layer. Trust me, it's much easier to sand a few thin coats than to grind down a huge, hard lump of filler. Let each coat cure completely before you even think about picking up the sander.

Pro Tip: Apply a light "guide coat" of a contrasting spray paint over the cured fairing compound. As you sand, the paint disappears from the high spots first. This instantly shows you where you still need to sand down or where you might need to add a touch more filler. It's a simple trick that takes out all the guesswork.

The Sanding and Priming Sequence

Sanding is a game of patience and progression. You'll start with a coarser grit to knock down the high spots and shape the compound, then gradually move to finer grits to erase the scratches from the previous step. This methodical approach is the real secret to a mirror-smooth finish.

Here's the general sanding progression I stick to for the best results:

- Initial Shaping: Kick things off with 80-grit sandpaper on a longboard or random orbital sander to fair the compound and blend the edges.

- Smoothing: Next, move up to 120-grit to remove the deeper scratches left by the 80-grit paper.

- Pre-Primer Finish: Finish up with 220-grit to create a smooth, uniform surface that's ready for primer.

Once you’re satisfied with the shape, it's time to apply a high-build marine primer. This stuff is fantastic because it fills in any tiny, remaining surface imperfections and provides a perfect base for the final topcoat to adhere to.

Applying the Final Topcoat

You're at the final hurdle! Whether you're using gelcoat or marine paint, the goal is a glossy, even finish that protects the repair from the elements.

Color matching is often the biggest challenge here. For a perfect match, you may need to get the original color code from your boat's manufacturer or have a local shop professionally scan it.

If you’re working with gelcoat, our guide on DIY gel coat boat repair for a perfect finish offers a deep dive into the specific techniques you'll need.

For marine paints, the "roll and tip" method can produce a spray-quality finish without the expensive equipment. It’s where one person rolls on the paint and another follows immediately behind with a dry brush to smooth it out. Once your topcoat has cured, a final wet sand and polish will bring out that brilliant, factory-new shine you've been working towards.

Answering Your Fiberglass Repair Questions

Even the clearest instructions can leave you scratching your head once you're in the middle of a project. It’s completely normal to hit a snag or two when you're learning how to tackle fiberglass boat repairs. We get questions all the time, so let's walk through some of the most common ones.

Can I Repair Fiberglass Below The Waterline?

You absolutely can, but this is one area where you can't cut corners on materials. For any repair that’s going to live below the waterline, you must use epoxy resin.

Polyester resin just won't cut it here. Epoxy is genuinely waterproof and creates a much stronger, more reliable bond. This is what keeps water from creeping in and causing those dreaded blisters or delamination down the road. The one non-negotiable? Make sure the repair area is completely bone dry before you even think about mixing that epoxy.

How Do I Match My Existing Gelcoat Color?

Ah, the artist's touch of boat repair. Matching faded, sun-beaten gelcoat is probably one of the biggest challenges to getting that "like it never even happened" finish. UV rays are relentless and change the original shade over time.

- DIY Kits: Your best bet for small jobs is a gelcoat repair kit. These come with a variety of pigments you can mix in, letting you play chemist and tint the gelcoat until you get a close match.

- Go to the Pros: For a truly perfect match, your boat's manufacturer might be able to provide the original color code. If that’s a dead end, you can carefully remove a small chip of the old gelcoat and take it to a marine paint specialist. They can often scan it and mix a custom batch for you.

A word of caution from experience: wet gelcoat looks different from cured gelcoat. Always, always do a small test patch on a spot that's out of sight. Let it fully cure so you can see the true final color before you commit to the main repair.

What Is The Difference Between Fiberglass Mat And Cloth?

Getting this right is fundamental to building a repair that lasts. Think of chopped strand mat (CSM) as your bulk filler. It’s made of short fibers randomly pressed together, so it’s fantastic for building up thickness in a hurry. But on its own, it doesn't offer a ton of structural strength.

On the other hand, woven cloth is the real muscle. It’s made of long, continuous fibers woven together into a tight pattern, giving it incredible tensile strength. This is what you need for any repair that has to handle stress.

For most significant repairs, you'll actually use both. A common practice is to alternate layers of mat and cloth. The mat acts like a bonding agent, helping the layers stick together, while the woven cloth provides the serious strength the repair needs.

From high-strength epoxy to professional-grade fairing compounds, Better Boat has every tool and material you need to get the job done right. You can check out our entire lineup of boat maintenance and repair products at our online store.