A Pro's Guide to Repair Pontoon Boat Problems

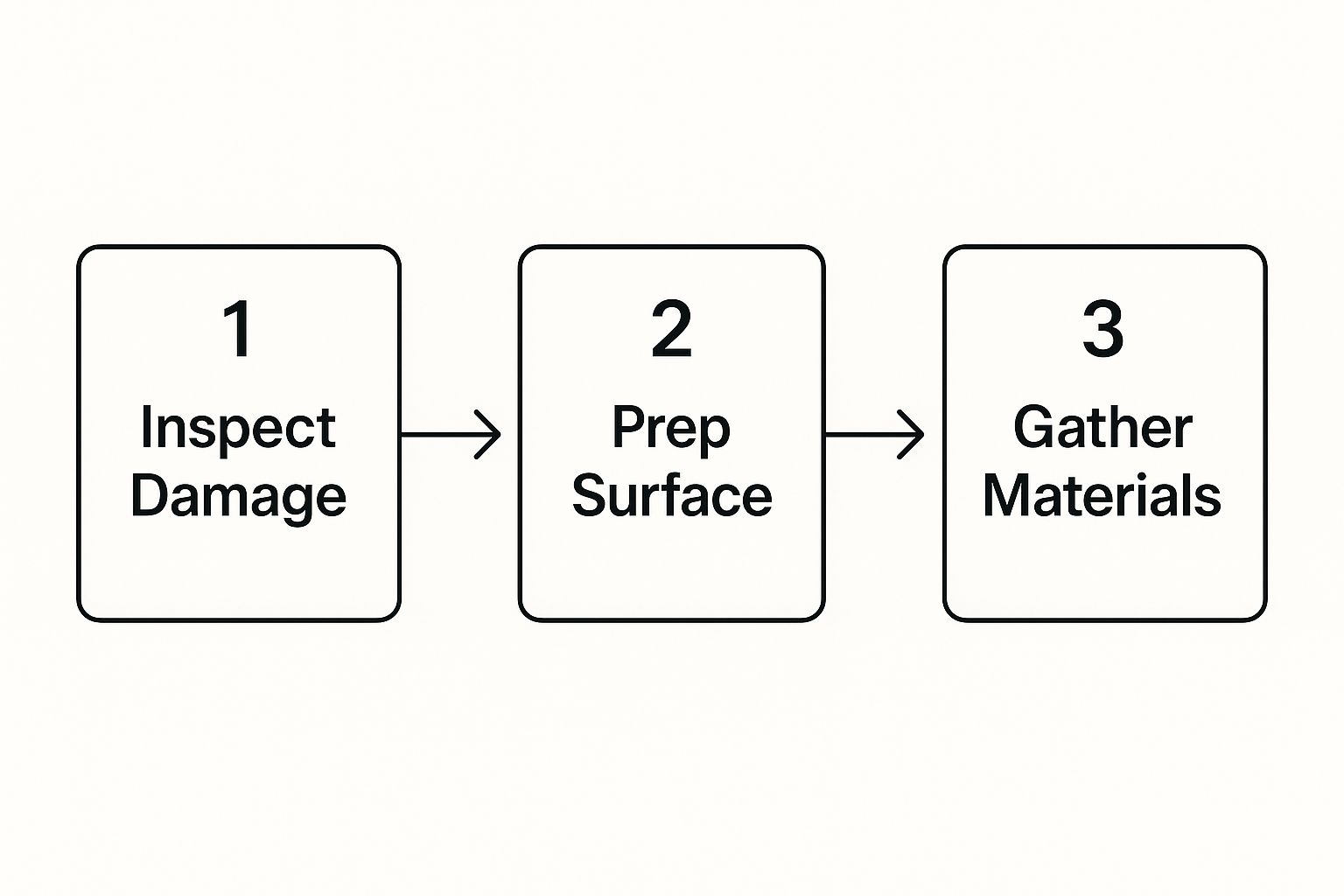

Before you can even think about fixing up your pontoon, you have to know exactly what you're dealing with. A full-on inspection is always your first move. It’s the only way to build a solid game plan that separates the quick DIY fixes from the jobs you’ll want to hand off to a pro.

This isn’t just about spotting a dent; it’s about understanding the real story behind the damage.

Your First Step Before Any Pontoon Repair

Jumping straight into a repair without a proper diagnosis is like trying to navigate a new lake without a chart. You’ll end up somewhere, but probably not where you intended. The goal here is to build a real-world "battle plan" for your pontoon by getting hands-on and looking beyond the obvious dings and scratches.

For instance, a small dent from a clumsy docking might be purely cosmetic. But a dent of the same size right next to a weld seam? That could be a whole different story, potentially compromising the tube's structural integrity. You have to know the difference.

Spotting Leaks and Weld Issues

Finding the source of a leak takes a bit of detective work. The easiest way to start is with a simple soap and water solution in a spray bottle. With the tube pressurized, spray it generously along the welds and any spot you think might be the culprit. Even a tiny pinhole leak will give itself away with a tell-tale stream of bubbles.

Pay extra attention to a few key areas:

- Weld Seams: Run your eyes—and the soapy water—along the entire length of every single weld. The spots where the deck brackets are attached are notorious for developing stress cracks.

- Previous Repairs: Old patches and sealant don't last forever. Check around their edges for any signs of lifting or new bubbling.

- Impact Points: Scratches and scuffs are clues. They often point to an underwater collision you might not have even noticed, and the resulting leak could be microscopic.

Assessing Dents and Structural Damage

Not all dents are created equal. A shallow, smooth depression on the side of a pontoon is usually a simple fix. But if you see a sharp, creased dent, that’s a sign the aluminum has been stretched and weakened. Trying to just pop that out yourself can often make things much, much worse.

Pro Tip: Run your hand over the damaged area. If you feel sharp edges or if the metal feels flimsy compared to the surrounding tube, that's a red flag for significant stress. This kind of damage often needs a professional welder to reinforce the weakened spot before you do any cosmetic work.

To help you get started, here's a quick checklist to triage the damage you find.

Pontoon Damage Triage Checklist

This table will help you quickly assess what you're looking at, how serious it is, and what your next steps should be.

| Issue Type | What to Look For | Severity Level | Recommended Action |

|---|---|---|---|

| Pinhole Leak | Bubbles forming with soapy water test | Low | DIY patch kit or marine sealant |

| Weld Crack | Bubbles along a weld seam | High | Professional welding required |

| Shallow Dent | Smooth, cosmetic depression | Low | Can often be popped out or left alone |

| Creased Dent | Sharp lines, stretched metal | Medium to High | Consult a professional; may need welding |

| Deck Soft Spot | Spongy or flexing floor underfoot | High | Immediate subfloor replacement needed |

| Scratches/Scuffs | Surface-level cosmetic marks | Low | Buffing, polishing, or touch-up paint |

| Gouge | Deep scratch that has removed metal | Medium | Requires filling and sanding; check for leaks |

Think of this as your starting point. Document everything you find, and you'll have a much clearer path forward.

Checking the Deck for Hidden Dangers

The health of your boat isn't just about the aluminum below. Your boat's deck is the foundation of every good day on the water, and its number one enemy is moisture. Take a walk around the entire boat, and really pay attention to how the floor feels under your feet.

Soft, spongy spots are the classic sign of water getting in and rotting the plywood subfloor. This isn't just a minor issue; it's a huge safety concern that needs to be addressed immediately. Make a note of the location and size of any soft spots you find.

Keeping your boat in top shape is more important than ever. The global boat repairing market was valued at a massive $7.64 billion and is only expected to grow, thanks to a booming boating industry. You can learn more about these trends in the full report on boat repairing.

By the time you finish your inspection, you should have a clear, prioritized list. This list will separate the small jobs from the big projects and give you the confidence to tackle your pontoon boat repair the right way.

Equipping Your Dockside Workshop

There's nothing worse than getting halfway through a pontoon repair only to realize you're missing a crucial tool or material. Trust me, I've been there. A well-stocked dockside workshop isn't just a convenience—it's what separates a quick, effective fix from a frustrating trip back to the marine store. This isn't just a random shopping list; it's about setting yourself up to handle the specific challenges of aluminum in a harsh marine environment.

Think about it this way: you wouldn't use a screwdriver as a chisel. The same logic applies here. Grabbing generic supplies from the local hardware store is a recipe for a failed repair. They simply can't stand up to the constant assault of water, sun, and vibration your pontoon endures.

Core Materials For Aluminum Repair

When you're working on the aluminum tubes—the very soul of your pontoon—using the right compounds is completely non-negotiable. Different types of damage call for different solutions to create a durable, watertight bond that can flex and move with the boat.

- Marine-Grade Epoxy Putty: For any deep gouges or scratches where the metal has been scraped away, this stuff is your best friend. A high-strength, sandable epoxy like Better Boat's Epoxy Putty Stick lets you literally rebuild the damaged section. Once it cures, it's as hard as a rock and can be sanded down perfectly smooth, creating a seamless surface that’s ready for a coat of paint.

- Flexible Polyurethane Sealant: This is what you need for sealing up seams, loose rivets, and tiny punctures below the waterline. Unlike a rigid epoxy, a good polyurethane sealant stays pliable. It absorbs the vibrations and flexing as the boat cuts through the water, which is critical for preventing the seal from cracking and failing down the road.

- Aluminum Cleaner and Degreaser: You simply can't get a good bond on a dirty, oxidized surface. Period. Before you apply any adhesive or sealant, that aluminum has to be spotless. A dedicated aluminum cleaner will strip away the oxidation, grime, and any oily residue, giving your repair materials a clean surface to grab onto.

A lesson learned the hard way: any good repair is 90% preparation and 10% application. Skipping the cleaning and prep work is the number one reason I see patches and sealants fail.

Essential Tools For The Job

Beyond the actual repair compounds, having a few specific tools makes the whole process go a lot smoother. Using the wrong tool can easily mar the soft aluminum, turning a simple fix into a much bigger headache.

One trick I’ve picked up is using a stainless steel wire brush (often as a drill attachment) to rough up the aluminum surface before applying epoxy. It’s just aggressive enough to create a good "key" for the epoxy to bond to, but not so harsh that it gouges or thins the pontoon wall. A big mistake is using a regular steel brush—it can leave behind tiny iron particles that will cause galvanic corrosion.

Here's a quick rundown of must-haves for your kit:

- Caulking Gun: Absolutely necessary for applying polyurethane sealant cleanly and evenly.

- Putty Knives: Get a flexible plastic set. They're perfect for mixing and spreading epoxy putty without scratching the aluminum.

- Sanding Blocks and Assorted Grit Sandpaper: You'll want a range of grits, from a coarse 80-grit for shaping epoxy to a fine 400-grit for feathering the edges for a glass-smooth finish.

- Cordless Drill: Invaluable for running a wire brush attachment and handling all the other small jobs that pop up.

Overlooked Safety Gear

When you're zeroed in on the repair, it's all too easy to let personal safety slide. But you're dealing with sharp metal edges and chemical compounds, so gearing up properly is just as important as the repair itself.

First on the list: a good pair of cut-resistant gloves. Scraped or dented aluminum can be surprisingly sharp and will slice you open in a heartbeat. Next, when you're sanding or working with any adhesives, a respirator with organic vapor cartridges is non-negotiable. The fumes from many marine-grade products are no joke.

Finally, always have safety glasses on. They protect your eyes from flying metal shavings and accidental chemical splashes. At the end of the day, a well-equipped workshop is one that protects both your boat and you.

Sealing a Leaking Pontoon Tube for Good

Finding water inside your pontoon tube is one of those gut-wrenching moments every boat owner dreads. It’s an instant sign of a breach, but don't panic. More often than not, it's a problem you can absolutely handle yourself with the right approach and a little patience. Getting a permanent, watertight seal isn't about just slapping on some goop; it's a precise process where preparation is everything.

The pontoon market is exploding. Once valued at around $8.22 billion, it's forecasted to skyrocket to $19.25 billion at a CAGR of 9.92%. This boom means more boats are on the water, and knowing how to do reliable repairs has never been more important. With three-tube models now making up 54% of the market for their stability, keeping all those tubes airtight is a top priority. You can dive deeper into these pontoon market sizing trends on towardsautomotive.com.

Pinpointing the Source of the Leak

Before you can fix anything, you have to play detective. The classic soap-and-water test is still the most reliable way to find even the sneakiest pinhole leaks. Grab a spray bottle and mix a generous amount of dish soap with water until you have a very bubbly solution.

With the boat out of the water, you'll need to slightly pressurize the leaking tube. A shop vac set to "blow" or a low-pressure air compressor is perfect for this. Seal the nozzle into the tube's valve and let it run for a few minutes. Don't go crazy—you just want enough pressure to force air out of any breach.

Now, start spraying your soapy solution all over the tube. Pay close attention to the usual suspects:

- Weld Seams: Hit every single weld, especially where deck support brackets are attached.

- Previous Patches: Old repairs can fail. Check around the edges for any signs of trouble.

- Scratches and Dents: Even a minor cosmetic scrape can hide a hairline crack.

Keep your eyes peeled for bubbles. A steady stream of tiny bubbles means a pinhole, while larger, faster-forming ones point to a more significant crack or puncture. Once you find the culprit, mark it clearly with a permanent marker so you don't lose it.

The Critical Role of Surface Preparation

Here’s a truth every seasoned marine mechanic lives by: a repair is only as good as the surface it's applied to. This is the single step where most DIY repairs go wrong. You simply cannot get a permanent bond on dirty, oxidized, or unprepared aluminum.

This is the non-negotiable foundation for any successful repair project.

First, clean the area around the leak—at least a few inches in every direction—with a strong degreaser and a coarse cloth. You need to get rid of every bit of grime, algae, and any oily film.

Next, you have to scuff up the surface. Aluminum develops a thin, tough layer of oxidation that sealants just can't penetrate. Using an 80-grit sandpaper or a stainless steel wire brush on a drill, abrade the area thoroughly. Your goal is to create a rough, textured "tooth" that the sealant can physically grab onto. You'll know you're done when the metal is bright and uniformly scratched.

Finally, give the entire area a final wipe-down with acetone or denatured alcohol on a clean, lint-free rag. This last step removes any microscopic dust and residue left from sanding, leaving you with the perfect canvas for a truly watertight seal.

Applying Sealant for a Permanent Bond

With the surface perfectly prepped, it's time to lay down the sealant. For any repair that will live below the waterline, a high-quality marine-grade polyurethane sealant is your only real choice. These are engineered to cure in the presence of moisture and stay flexible, which is absolutely crucial for absorbing the constant shocks and vibrations a pontoon endures on the water.

Key Takeaway: Never, ever apply new sealant directly over old, failing sealant. You must remove every last bit of the old material first. Applying new over old is like putting a new bandage on a dirty wound—it’s guaranteed to fail.

Load your sealant into a caulking gun and apply a generous bead directly over the pinhole or crack. Use a plastic putty knife to tool the sealant, pressing it firmly into the repair area to squeeze out any air bubbles. You want to feather the edges out smoothly from the center.

Choosing the right sealant is critical, as some are more permanent than others. For a detailed breakdown of your options, check out our guide on 3M 4200 vs 5200 sealants.

Now for the hard part: waiting. Allow the sealant to cure completely according to the manufacturer's instructions. This can take anywhere from 24 hours to a full week, depending on the product, temperature, and humidity. Rushing this step is a classic mistake that results in a weak bond. A little patience now ensures your repair will hold strong for many seasons to come.

Fixing Dents and Gouges in Aluminum

It happens to the best of us. A misjudged docking, a rogue log floating just beneath the surface, or an unlucky bounce on the trailer—dents and gouges are a fact of life for any hardworking pontoon. They might look disastrous, but you can fix a surprising amount of this damage yourself, bringing back both the looks and the integrity of your tubes.

The trick is knowing what you're up against. A minor cosmetic ding is a whole different ballgame than a deep gouge that’s torn away metal. Using the right technique for the job will keep you from turning a small problem into a much bigger headache. With a bit of patience, you can smooth out those battle scars and get your pontoons looking sharp again.

Handling Minor Dents and Dings

For those shallow, smooth depressions from a gentle bump, your first instinct shouldn't be brute force. Aluminum has a memory, and your real goal is to gently persuade it back to its original shape without creating new creases or stretches. This part of your pontoon boat repair is all about finesse.

Your go-to tools here are often a simple rubber mallet and a wooden block. Place the block on the high spots around the dent and give it a few gentle taps with the mallet. The idea is to slowly work the surrounding metal, encouraging the dent to pop back out on its own. Always work from the outside edges of the dent and move inward.

Another great trick, pulled straight from the auto body world, is a suction cup dent puller. If the dent is smooth and wide enough to get a solid seal, a few firm, controlled pulls might be all you need to pop it right out.

Pro Tip: Whatever you do, resist the urge to just start hammering on the dent from the inside. This almost always stretches the soft aluminum, creating an "oil can" effect where the metal just flexes in and out. Trust me, that's a much harder problem to fix than the original dent.

Filling Deeper Gouges with Epoxy

When an impact does more than just dent the tube and actually scrapes metal away, it's time to switch from pulling to filling. A deep gouge is more than an eyesore; it's a breach in the tube's protective surface that can become a hot spot for corrosion down the line. This is where a top-notch, sandable marine epoxy becomes your best friend.

A product like Better Boat's Epoxy Putty Stick is perfect for this kind of repair. It’s a two-part compound that you just knead together by hand to activate. Once cured, it's rock-hard, completely waterproof, and bonds like crazy to properly prepped aluminum.

The process is pretty straightforward:

- Clean It Up: First things first, scrub the gouge and the area around it with a good degreaser to get rid of any grime, oil, or wax.

- Scuff the Surface: Grab some 80-grit sandpaper and get aggressive. Scuff up the inside of the gouge and about an inch of the aluminum around its edges. You're creating a rough "tooth" that the epoxy can really bite into.

- Wipe It Down: Give the whole area one last wipe with acetone or denatured alcohol to lift away any sanding dust.

- Mix and Apply: Knead the epoxy putty until it’s one uniform color, then press it firmly into the gouge. You want to overfill it just a bit, so the putty sits slightly proud of the pontoon's surface.

Sanding for a Seamless Finish

Let the epoxy fully cure (always check the instructions, but it's typically around 24 hours). Now for the final stage, where you turn that rough patch into an invisible mend. The goal here is to sand the hardened epoxy perfectly flush with the aluminum, creating a transition so smooth you can't even feel it.

Start with a coarser paper, like 120-grit, wrapped around a sanding block. This will help you knock down the bulk of the excess epoxy quickly and evenly. As you get the patch closer to the level of the tube, switch to a finer 220-grit paper to smooth out the deeper scratches.

For the final blend, move to a 400-grit wet sandpaper. This will let you feather the edges of the repair flawlessly into the surrounding aluminum. Taking your time on this step is what makes the repair disappear. When you're done, the filled area should blend right into the pontoon's original contour.

With the gouge filled and sanded smooth, your pontoon tube is structurally sound again. You've created the perfect foundation for priming and painting. To get that final, factory-fresh look, check out our complete guide on how to repaint an aluminum boat. Following those steps will make your repair truly vanish, leaving your pontoon looking good as new.

Reviving Your Decking and Furniture

A solid set of tubes is the foundation of your pontoon, but what’s happening up top is just as important. A worn-out deck and tattered furniture can ruin a great day on the water fast. This is where we get into those critical topside repairs that bring back the comfort, safety, and pride in your pontoon.

First up, we'll tackle the number one enemy of any pontoon deck: the dreaded soft spot. These aren't just minor cosmetic fixes; they're essential projects. From rebuilding the floor under your feet to bringing tired old seats back to life, a little bit of work here makes a world of difference.

Diagnosing and Repairing Deck Rot

It usually starts with a subtle feeling. You step on a certain spot and notice a bit of give, maybe a spongy sensation underfoot. That's the classic sign that water has gotten in and the plywood subfloor is starting to rot. This isn't something you can put off—it's a real safety issue. The only proper fix is to get in there and replace the damaged wood.

To see how bad the problem is, you'll need to pull up the carpet or vinyl flooring around the soft spot. Don't be surprised if you find dark, damp, or even crumbling plywood underneath. Grab a screwdriver or an awl and start probing the wood around the area. Your goal is to find the "edges" of the rot, where the wood turns firm and solid again.

Once you’ve mapped out the rotten section, set a circular saw to the exact depth of the plywood and cut it out. Be incredibly careful here. You absolutely do not want to cut into the aluminum cross members supporting the deck. With the bad section removed, you now have a perfect template for your new piece of marine-grade plywood.

Replacing Deck Sections and Flooring

When you're patching the deck, the material you choose is everything. Never use standard plywood from a hardware store. I guarantee it will rot out within a single season. You absolutely must use marine-grade plywood, which is constructed with waterproof glue designed to handle the constant exposure to moisture.

Cut your new patch to fit the opening as precisely as you can. Before you drop it in place, it's critical to seal every single side—especially the fresh-cut edges—with a quality marine epoxy or waterproof sealant. This is the step that prevents moisture from wicking into your brand-new wood. Once it's sealed, secure the patch to the aluminum cross members using stainless steel screws.

Now that the structural repair is solid, you can think about flooring.

- Marine Carpet: This is the traditional choice. It's comfortable on bare feet but can hold moisture, which means you have to stay on top of keeping it clean and dry.

- Vinyl Flooring: A very popular upgrade these days. Marine vinyl is completely waterproof, a breeze to clean, and incredibly durable.

Whichever option you go with, make sure you use a high-quality, water-resistant adhesive specifically made for marine applications to glue it down.

Practical Fixes for Worn Furniture

Cracked vinyl seats and wobbly chairs aren't just an eyesore; they're uncomfortable and can even be unsafe. The good news is that these are often straightforward fixes you can knock out in an afternoon. These kinds of repairs are becoming more common as the boating community grows. In the U.S. alone, annual sales of boats and marine services recently hit an estimated $57.7 billion, and pontoons are a huge part of that. As more families get into boating, knowing how to do these basic repairs becomes even more valuable.

For small rips and cracks in your upholstery, a simple vinyl repair kit can be a lifesaver. These kits usually come with a color-matched compound that you apply to the damaged spot. It cures into a flexible, tough patch that stops a small tear from becoming a huge problem. For a more detailed walkthrough, check out our complete guide on how to repair vinyl boat seats.

A wobbly captain's chair or bench seat is often just a case of loose mounting hardware. Before you assume the deck is shot, grab a wrench and check if all the bolts securing the seat base to the deck are tight. A season's worth of vibration can easily work them loose.

If tightening the bolts doesn't fix the wobble, the plywood under the seat base might be compromised. An easy way to reinforce this is by adding a larger backing plate made of aluminum or another piece of marine-grade plywood under the deck. This spreads the load over a wider area, giving your seat a much more solid and secure foundation.

Common Questions on Pontoon Boat Repair

After years in the boating world, I’ve heard just about every question you can imagine about fixing up a pontoon. From tiny dings that bug you to damage that looks like a season-ender, most owners run into the same handful of problems. This is where we tackle those head-on.

My goal here is to give you the real-world advice you need to figure out what you can handle yourself and when it’s time to call in a pro. Knowing the difference saves you a ton of time, stress, and, frankly, a lot of money down the road.

Can I Really Fix a Large Hole Myself?

This is the big one—the question I get asked more than any other. And the honest answer is: it depends on what you mean by "large."

If you’ve got a small puncture, a pinhole leak, or a minor crack, you can absolutely tackle that yourself. A high-quality, marine-grade epoxy or sealant is your best friend here. When you prep the surface right, these products create a bond that’s incredibly strong and permanent.

But, if you’re looking at a hole bigger than a silver dollar, a long crack snaking along a weld, or any dent that has actually creased the aluminum, you need to stop. That’s a job for a professional marine welder, no question. Aluminum welding is a different beast entirely and requires specialized gear to get a safe, watertight seal that won’t pop open under pressure.

How Often Should I Inspect My Pontoons for Problems?

With boats, an ounce of prevention is worth a truckload of cure. I tell everyone to schedule two deep, thorough inspections every single year. Do the first one right before you launch for the season and the second as soon as you pull the boat out for winter storage.

On top of that, make a quick walk-around part of your pre-launch ritual. It only takes a minute or two to eyeball the tubes, check the deck, and glance at the railings.

The most critical time for an inspection is right after an impact. If you have a rough docking or hear a "thump" from something underwater, take five minutes to check things over as soon as you can. Catching a small problem at that moment is the single best way to keep it from turning into a major, season-ruining headache.

What Is the Best Way to Prevent Future Pontoon Damage?

You can't bubble-wrap your boat, but you can definitely stack the deck in your favor. It all comes down to building a few proactive habits that will dramatically cut down your chances of needing a major repair.

Here are a few simple strategies that make a huge difference:

- Always Use Fenders: Seriously. Pontoon fenders are the cheapest insurance you can buy against dock rash, scrapes, and dings. They should be the first thing out and the last thing in every time you approach a dock.

- Be Mindful in Shallow Water: Get to know the waters you frequent. If you’re exploring a new area, be extra cautious and slow down. Hidden stumps, rocks, and sandbars are the number one cause of serious pontoon damage.

- Check Your Trailer Bunks: When you’re trailering, make sure the bunk boards are properly aligned to support the full length of the pontoons. If they're off, they can put a ton of stress on the tubes and welds over time.

My Pontoon Deck Feels Spongy. What Does That Mean?

A soft or spongy spot under your feet is the classic, tell-tale sign of wood rot. It means water has penetrated your flooring and gotten into the plywood subfloor, and now the wood is decaying. This is a big deal—it’s a safety issue you absolutely cannot ignore.

The only proper fix is to get your hands dirty. You’ll need to pull up the marine carpet or vinyl flooring to get to the plywood underneath. From there, you have to cut out every last piece of soft, compromised wood and replace it with fresh, marine-grade plywood. Don't skip the final step: seal the new wood thoroughly on all sides before putting your flooring back down, or you'll be doing this all over again in a few years.

At Better Boat, we know that a good repair starts with great materials. From our tough-as-nails Epoxy Putty Stick to our full line of cleaners and sealants, we’ve got what you need to fix your pontoon with confidence. Check out our complete range of products at https://www.betterboat.com.