3M 4200 vs 5200 Choosing the Right Marine Sealant

When you're standing in the aisle looking at 3M 4200 vs. 5200, the choice really comes down to one simple question: do you ever want to take this apart again? Think of 3M 5200 as a permanent, structural weld in a tube, while 3M 4200 creates a tough, waterproof seal that you can still undo later. That single distinction is the key to every decision you'll make between the two.

Understanding the Core Difference in Marine Sealants

Picking the right marine sealant isn't about finding the "best" product, but the correct one for the job at hand. These adhesives are specialized tools, and grabbing the wrong one can lead to a world of frustration, hours of extra labor, and even potential damage to your boat.

At the heart of it, you need to know their intended roles. 3M 5200 is the industry legend for permanent bonds that actually add to your boat's structural integrity. On the flip side, 3M 4200 is made to be a stout but flexible sealant for parts that you know will need service or replacement down the road.

Permanent vs. Serviceable Bonds

This difference all comes down to their chemical makeup and brute strength. While both are heavy-hitters in 3M's marine adhesive lineup, 3M 4200 is specifically formulated with roughly half the bonding strength of 5200. That's not a weakness; it's a feature that allows for eventual disassembly without destroying your gelcoat.

The entire decision boils down to permanence versus serviceability. If a part might ever need to be replaced or adjusted—think deck hardware, transducers, or inspection plates—4200 is your go-to. For structural joints you never, ever want to move again, 5200 is the only real answer.

Here’s a quick way to think about it:

- 3M 5200 is for: Sealing through-hulls below the waterline, bonding the hull-to-deck joint, and setting keels.

- 3M 4200 is for: Bedding cleats, winches, stanchions, hatches, and any other piece of hardware you might need to get to later.

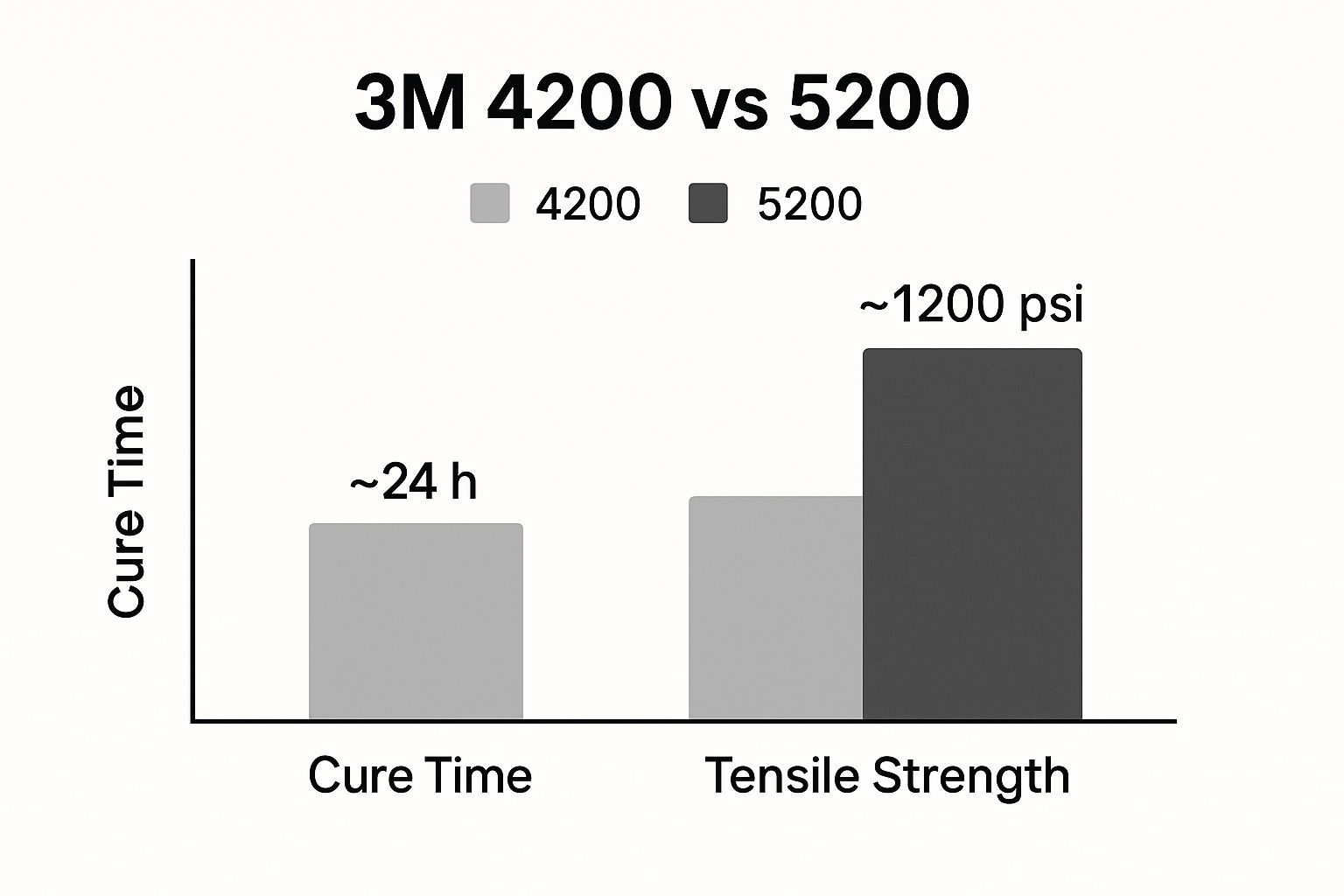

Breaking Down the Key Performance Numbers

To really get to the bottom of the 3M 4200 vs 5200 choice, you have to look beyond the labels and dig into the specs that define how they perform on your boat. These numbers aren't just for show; they dictate how you'll work with the product and how it will hold up to years of abuse from the sun and salt. The two big ones are tensile strength and cure time.

Tensile strength is just a fancy way of saying how much force it takes to rip a bond apart. For 3M 5200, that number is a massive 700 psi, which is strong enough to be considered a structural part of your boat. It’s not just sealing; it's bonding.

On the other hand, 3M 4200 clocks in at 300 psi. While that’s still incredibly strong, it’s designed to be removable. This isn't a weakness—it's the whole point, allowing you to take things apart later without destroying your gelcoat.

3M 4200 vs 5200 At a Glance

Sometimes you just need a quick cheat sheet. This table cuts right to the chase, highlighting the core differences between these two workhorse sealants.

| Characteristic | 3M 4200 Fast Cure | 3M 5200 |

|---|---|---|

| Tensile Strength | 300 psi | 700 psi |

| Primary Use | Semi-permanent, serviceable | Permanent, structural |

| Full Cure Time | ~24 hours | 7 days |

| Removability | Removable with tools | Extremely difficult to remove |

This side-by-side makes it clear: 4200 is for jobs you might need to undo, while 5200 is for things you never want to move again.

Curing Time and What It Means for Your Project

Cure time is the other major factor that will directly impact your project's schedule. This isn't an instant process; it goes in stages from getting tack-free (so you don't smudge it) to reaching its full, rock-solid strength. While the "Fast Cure" versions help, the basic differences are still there.

- 3M 4200 Fast Cure will be tack-free in a couple of hours and pretty much fully cured within 24 hours. That speed is a huge plus when you need to get a job done and get the boat back on the water without waiting a week.

- 3M 5200, even the Fast Cure version, takes its sweet time. It needs around 48 hours just to become tack-free and a full seven days to get to that legendary maximum strength.

This image lays out the core differences in strength and cure times for the standard versions, giving you a great visual snapshot.

You can see right away how 5200’s incredible strength is tied to that much longer cure time, cementing its reputation as the go-to for permanent bonds.

Don't Forget the Weather

It’s easy to forget, but temperature and humidity are huge players here. Polyurethane sealants like these actually use moisture from the air to cure. Hot and humid weather will make them set up faster, while cold, dry air can slow the process to a crawl.

Always check the forecast before you start a big sealing project to make sure you get a solid, reliable bond. If you're exploring other options, you can find a quality marine sealant adhesive caulk that might be a better fit for different jobs around your vessel.

Key Takeaway: The slow cure time of 3M 5200 is directly linked to its immense strength. The chemical process that creates such a powerful, permanent bond simply takes longer to complete, demanding more patience from the installer for a far more robust result.

When to Use 3M 5200 for a Permanent Bond

When something on your boat needs to stay put forever, you reach for 3M 5200. Let's be clear: this isn't just a sealant. It's a high-strength adhesive that creates a bond so powerful it's often stronger than the fiberglass it's joining. The mindset here is simple: "bond it and forget it."

Think about the most critical joints on your boat—the ones you never want to fail or even have to think about again. Those are the perfect jobs for 5200. It’s the absolute go-to for any application where structural integrity is the top priority and you have no intention of ever taking it apart.

Structural Applications and Below-the-Waterline Confidence

The choice between 3M 4200 vs 5200 really snaps into focus when you're dealing with high-stress, permanent installations. For anything below the waterline where a failure could be catastrophic, 5200 is the only thing that will let you sleep at night.

Here are the classic situations where only 5200 will cut it:

- Hull-to-Deck Joints: This is probably its most common use. The adhesive basically fuses the two largest parts of your boat into one solid, unified structure.

- Setting Keels: When you're attaching a keel, that bond has to fight against immense hydrodynamic forces. 5200 makes sure it's not going anywhere.

- Thru-Hull Fittings (Below Waterline): Any fitting that penetrates the hull below the water needs a seal that is absolutely, positively waterproof for decades to come.

- Stringer and Bulkhead Bonding: For installing or repairing the boat's internal fiberglass "skeleton," 5200 delivers the raw structural adhesion you need.

CRITICAL WARNING: Do not use 3M 5200 on anything you might need to service, adjust, or replace down the road. Trying to remove a part sealed with 5200 will almost certainly destroy the part, the surrounding gelcoat, or the fiberglass itself. The removal process is, by design, a destructive one.

Choosing 5200 is a serious commitment. But for the right job, it's the smartest decision you can make, turning a potential weak point into a source of incredible strength.

When to Use 3M 4200 for a Strong, Serviceable Seal

While 3M 5200 is the undisputed king of permanent bonding, its less aggressive sibling, 3M 4200, is the true workhorse for most day-to-day boat jobs. Its whole purpose is to create a strong, flexible, and waterproof seal that you can actually undo later without a massive fight. Think of it as the go-to choice for anything you might need to service, replace, or re-bed down the road.

The key to getting 4200 right is to see its lower tensile strength not as a weakness, but as its greatest feature. This was a deliberate engineering choice. It allows you to remove hardware with standard tools, often without causing any damage to your boat’s precious gelcoat. The choice between 3M 4200 vs 5200 gets pretty simple when future access is even a remote possibility.

Ideal Use Cases for 3M 4200

This sealant really shines when you're bedding deck hardware and fittings that see a lot of vibration but might need to be removed someday. It strikes the perfect balance between adhesion and flexibility, creating a watertight gasket that still allows for serviceability.

Common jobs where 3M 4200 is the smart choice include:

- Bedding Deck Hardware: Cleats, winches, and fairleads are perfect examples. You need a rock-solid, waterproof seal, but you might want to upgrade that hardware or re-bed it years from now.

- Mounting Stanchion Bases: Stanchions take a beating and often need to be removed for repair or replacement. Using 4200 gives you a durable seal that won't turn that job into a nightmare.

- Sealing Hatches and Portlights: These parts need a totally reliable seal against the elements, but they're designed to be serviced. Using 5200 here would turn a simple re-glazing job into a destructive mess.

The real beauty of 3M 4200 is its mix of fast cure time and reliable strength. For projects where you need the boat back in the water quickly without cutting corners on the seal, 4200 is what the pros reach for.

Another huge plus is its faster cure time. Forget about the week-long wait for 5200 to fully cure. 3M 4200 Fast Cure is tack-free in about an hour and hits its full-strength bond in roughly 24 hours.

This quick turnaround makes it incredibly practical for weekend projects and routine maintenance, cementing its role as the versatile, go-to sealant for most above-the-waterline tasks.

Best Practices for Application and Removal

Choosing between 3M 4200 vs 5200 is one thing, but how you apply it is what really separates a professional job from a leaky mess. The success of your seal comes down to good old-fashioned prep work. Even the toughest marine sealant won't stick if the surface isn't ready.

Before you even think about loading the caulk gun, get those surfaces spotless. They need to be completely clean, dry, and free of any old gunk, wax, or grime. I always wipe down the area with acetone to make sure every last bit of contaminant is gone.

If you're working with fiberglass, give it a light scuff with some 80-grit sandpaper. This gives the sealant a rougher surface to bite into, creating a much stronger mechanical bond.

Managing the Removal Process

Getting these sealants off is where you'll really see the difference between the two. Removing 3M 4200 is manageable. It’s designed to be strong, but not permanent. Usually, a good putty knife and some patience are all you need to break the bond without wrecking your gelcoat.

3M 5200, on the other hand, is a whole different beast. Taking it off is a serious job that requires a battle plan and the right tools. It's not coming off without a fight.

- Bring the Heat: A heat gun, used carefully, can soften the sealant just enough to make it easier to cut through. Don't overdo it, though.

- Cut it Out: For stubborn bonds, you'll often need to saw through it with piano wire or a specialized de-bonding tool.

- Use a Debonder: Products like DeBond Marine Formula are made specifically to break down the adhesive. You have to score the bead of 5200 first, then apply the chemical and let it work its magic.

The bottom line is this: 4200 is made to be removed with regular tools if needed. 5200 is made to stay put, and removing it often means cutting, grinding, and potentially damaging the surfaces it's holding together.

Proper technique ensures you're getting the performance you paid for, whether that’s a permanent structural bond or a seal you can service down the road. And for those bigger projects that go beyond simple sealing, it's a good idea to understand the role of epoxy resin for boat repair to keep your vessel's integrity in top shape.

When you're dealing with marine adhesives and epoxy resin, picking between 3M 4200 and 5200 isn't just another task on your project list—it's a critical decision for your boat's safety and long-term health.

Out on the water, every single seal and bond is constantly under attack from water, vibrations, and harsh weather. A failed seal isn't a minor annoyance; it can quickly escalate into a serious headache, from a persistent leak to a major structural failure.

This is exactly why the pros rely so heavily on high-performance adhesives. The market for these products is massive—valued at USD 495 million back in 2022—and it's only getting bigger as more people demand rock-solid bonding solutions for building and repairing boats. If you're curious about the numbers, Grand View Research has a detailed breakdown of this trend.

Think of it this way: Choosing the right adhesive is a direct investment in your boat’s seaworthiness. It's what ensures everything from a deck cleat to a vital thru-hull fitting holds fast and performs without fail, keeping your boat and everyone on it safe.

Making a smart, calculated choice here means your boat will be ready for whatever the marine environment throws at it. Whether you're just mounting new hardware or tackling a bigger job like figuring out how to repair cracked fiberglass, the right sealant is your first and best line of defense.

Your Questions Answered: 3M Sealants

Even after breaking down the differences, you probably still have a few questions about 3M 4200 vs. 5200. We get it. Let's tackle some of the most common ones we hear from boat owners to help you lock in your decision.

Can I Use 3M 5200 Below the Waterline?

You absolutely can. In fact, you should. 3M 5200 is the gold standard for anything permanent and structural below the waterline. Think thru-hulls, keel joints, and strut mounts—places where a failure is simply not an option. Its massive strength and completely waterproof bond make it the go-to for these critical jobs.

How Long Do I Really Have to Wait for a Full Cure?

Patience is a virtue, especially when you're working with 5200. While the 3M 4200 Fast Cure will give you a full-strength bond in about 24 hours, the standard 3M 5200 needs a full seven days to reach its legendary holding power. Keep in mind that cold weather or high humidity can stretch that timeline out even longer.

Quick tip: "Tack-free" doesn't mean "fully cured." If you rush the process, especially with 5200, you're compromising the integrity of that bond before it ever has a chance.

What if I Used 5200 by Mistake?

Okay, don't panic. Removing 3M 5200 is a tough job, but it's not impossible. You'll need a combination of tools and tactics: a heat gun to soften it, specialized cutters like piano wire to saw through it, and a chemical de-bonding agent to break its grip. Just be prepared for a fight—it's a labor-intensive process that might leave some cosmetic damage behind.

Is 3M 4200 Strong Enough for Deck Hardware?

For sure. 3M 4200 is the perfect choice for bedding deck hardware like cleats, winches, and stanchions. It provides a seriously tough, waterproof seal with 300 psi of tensile strength, which is more than enough for the job. The best part? You can still remove that hardware later for servicing without tearing up your boat's gelcoat, making it the ideal sealant for most fittings above the waterline.

For all your marine maintenance needs, from powerful sealants to premium cleaning supplies, trust Better Boat to keep your vessel in top condition. Explore our complete collection of boat care products at https://www.betterboat.com.