Your Complete Guide to Anchor Brackets for Boats

So, what exactly is an anchor bracket? Think of it as a dedicated piece of hardware designed to securely hold, guide, and deploy your anchor. It’s a simple but brilliant addition that acts as a protective guide, preventing the anchor from scraping against your hull. More importantly, it ensures a smooth, controlled drop and retrieval every time, transforming anchoring from a clunky chore into a safe and efficient process.

Why a Quality Anchor Bracket Is Your Boat's Best Friend

Picture your boat's bow without a proper anchor bracket for a second. Every time you drop or pull up your anchor, you're risking gouges in the gelcoat, chips in the fiberglass, and unnecessary wear and tear on your anchor rode. It’s like trying to work in a shop with tools scattered everywhere—inefficient, messy, and just asking for trouble. An anchor bracket brings some much-needed order to that chaos, serving as the unsung hero of your whole anchoring system.

This specialized hardware provides a dedicated, low-friction path for your anchor line or chain. It guides the anchor smoothly over the bow, which means less effort for you and an end to that awful grating sound of metal dragging against your boat. This isn't just about making life easier; it’s a critical part of protecting your vessel.

Protecting Your Investment

A well-designed anchor bracket does a lot more than just hold your anchor. It's a permanent shield for your bow. The repeated impact and friction from a heavy anchor can cause some serious cosmetic and even structural damage over the years. By installing a robust bracket, you create a buffer that absorbs all that abuse, preserving your boat’s finish and integrity for the long haul.

It also keeps your anchor from swinging or rattling around while you're underway. A loose anchor isn't just annoying—it's a real safety hazard that can cause damage or even break free in rough seas. The right bracket makes sure your anchor stays put until you need it.

By providing a fixed, reinforced point for deployment, a high-quality anchor bracket significantly reduces the risk of hull damage and line chafe, turning a potential weak point into a source of strength and reliability.

The benefits are pretty clear. The widespread adoption of modern anchor brackets for boats lines up with a noticeable drop in anchoring-related incidents. Proper mounting and guidance are fundamental to safe anchoring, helping you avoid mishaps that can lead to costly repairs or dangerous situations on the water. You can actually read the full research about trends in the global ship anchor market if you want to dive deeper.

For a quick look at why this piece of hardware is so crucial, here are the main advantages.

Key Benefits of a Dedicated Boat Anchor Bracket

| Benefit | Impact on Your Boating Experience |

|---|---|

| Protects the Hull | Prevents ugly scratches, scrapes, and gouges on your bow and gelcoat. |

| Reduces Rode Chafe | Guides the anchor line smoothly, extending its lifespan and preventing fraying. |

| Enhances Safety | Secures the anchor when stowed, preventing it from becoming a hazard underway. |

| Improves Operation | Makes deploying and retrieving the anchor faster, easier, and much quieter. |

| Preserves Boat Value | Keeps your vessel looking great and avoids costly cosmetic repairs down the line. |

Ultimately, a quality bracket makes your entire boating experience better and safer.

Core Functions of an Anchor Bracket

When you boil it all down, an anchor bracket serves three primary functions that dramatically improve your time on the water:

- Vessel Protection: It stops the anchor fluke and shank from scratching, scraping, or denting your bow and gunwale during deployment and retrieval.

- Smooth Operation: It provides a low-friction roller or surface, letting the anchor rode pay out and come back in with minimal resistance and wear.

- Secure Stowage: It offers a safe, stable home for the anchor when you're not using it, keeping it secure and ready for immediate deployment.

By handling these key jobs, a quality anchor bracket gives you peace of mind, boosts your safety, and protects the value of your boat.

Matching the Right Bracket to Your Anchor and Boat

Picking an anchor bracket isn't a one-size-fits-all deal. The right choice comes down to a careful balance between your boat’s design, the specific anchor you use, and how you spend your time on the water. It’s a lot like choosing the right tires for a vehicle—what works on a sports car is going to be a disaster on an off-road truck.

In the same way, the bracket you need is dictated by the mechanics of your anchor and the shape of your bow. A bad match can lead to poor performance, frustrating retrievals, and even damage to your boat. The first step to getting it right is understanding the common styles out there.

Common Bracket Styles and Their Best Uses

Most boaters will find what they need among a few key designs. Each style of anchor brackets for boats is built to solve a specific set of challenges related to anchor types and boat shapes.

The most common and versatile option is the Bow Roller. This is the workhorse of anchor brackets. It mounts right on the bow and gives you a smooth roller system that guides the anchor rode and keeps your hull from getting chewed up. These are great for a huge variety of boats and anchors, especially the traditional fluke-style ones.

For bigger boats or those with a prominent bowsprit, an Anchor Pulpit is usually the way to go. This is basically an extended platform with a built-in roller that holds the anchor further away from the hull. That extra clearance is a game-changer, preventing the anchor from swinging back and smacking your bow in rough seas.

Finally, a Transom Mount is a super practical solution if you need a secondary or stern anchor. These are perfect for smaller boats or for anglers who need to hold their position over a hot fishing spot.

Pairing Brackets with Specific Anchor Types

The real secret to a flawless anchoring system is matching the bracket to your anchor’s design. How your anchor moves when you're pulling it up is the most important thing to think about.

- Fluke-Style Anchors (Danforth): These classic, flat anchors are a perfect match for standard bow rollers. Their simple design lets them drop and come back up smoothly without needing any fancy hardware.

- Plow-Style Anchors (Delta/CQR): These anchors have a fixed shank, so they often need a pivoting or self-launching bow roller. The pivot allows the anchor to articulate as it comes over the bow, helping it seat itself properly without you having to fight with it.

- Claw-Style Anchors (Bruce): Much like plow anchors, claw anchors really benefit from a well-designed roller that can handle their unique three-claw shape. This ensures they don’t get hung up or damage the bow on their way in.

A high-quality bracket paired with a reliable anchor creates a seamless system you can trust. The goal is to make deployment and retrieval so smooth that the anchor seats itself securely every time, without you having to wrestle it into place.

Getting the size right is just as critical as the style. You have to be sure the bracket can handle your anchor's weight and the forces it will face. For a deeper dive, check out our complete boat anchor size chart. It will help you figure out the right anchor for your vessel, which is the first step in picking the right bracket.

Choosing the Best Materials for Your Boating Environment

The life and reliability of your anchor bracket come down to one thing: the material it’s made from. Picking the right one is a lot like choosing the right jacket for the weather. What works on a calm, sunny day just won’t cut it in a hurricane. For boaters, this means you’ve got to match the bracket’s material to the unique challenges of the water you call home.

The three main players in the world of anchor brackets for boats are marine-grade stainless steel, galvanized steel, and aluminum. Each one has its own personality, with a distinct set of strengths and weaknesses. Understanding these differences is the key to making a smart investment in your anchoring setup.

The Fortress of the Sea: Stainless Steel

Think of marine-grade 316 stainless steel as a fortress against the constant assault of saltwater. Its secret weapons are chromium and molybdenum, which create a passive, corrosion-resistant shield that actively fights off rust and pitting. This makes it the undisputed champion for coastal cruisers and anyone who spends time in salty or brackish water.

Sure, it sits at the higher end of the price range, but its durability is second to none. That initial investment often pays for itself by saving you from premature replacements down the road. If you're looking for a fit-it-and-forget-it solution that can handle the absolute toughest conditions, 316 stainless steel is the gold standard. For a deeper dive, you can learn more about fighting salt corrosion on your boat.

Galvanized Steel: The Workhorse

Galvanized steel is the tough, budget-friendly workhorse of the marine world. It's essentially carbon steel that’s been dipped in a protective bath of molten zinc. This zinc layer then sacrifices itself to protect the steel underneath from corrosion, a process known as cathodic protection.

While it doesn't have the mirror finish of stainless steel, its ruggedness is undeniable. It offers excellent strength and solid rust resistance, making it a great choice for both freshwater and saltwater boaters who want durability without the premium price. In fact, its effectiveness is proven worldwide; anchor brackets in typhoon-prone regions often feature galvanized finishes, which can extend their lifespan by up to 50%.

Lightweight and Agile: Aluminum

Aluminum is the lightweight champion of the group. It offers impressive corrosion resistance, especially in freshwater environments. For owners of smaller boats, jon boats, or kayaks, shedding weight at the bow is a huge plus, and aluminum brackets deliver this without sacrificing performance in less demanding conditions.

The trade-off? It’s not as strong or abrasion-resistant as its steel cousins. While it holds its own against rust, it's more susceptible to dings, dents, and galvanic corrosion if you install it with the wrong kind of fasteners.

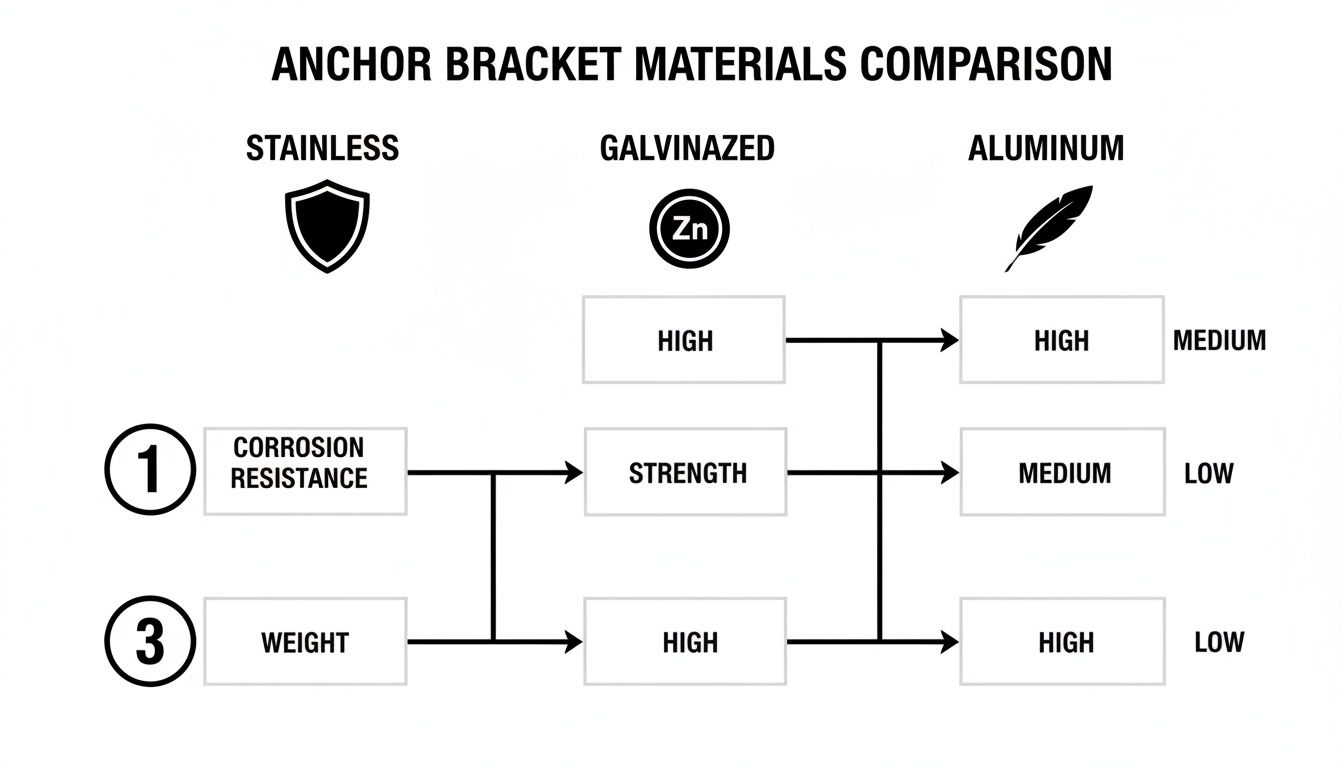

To help you size up the options, here’s a quick side-by-side comparison to make the choice a bit clearer.

Anchor Bracket Material Comparison

| Material | Corrosion Resistance | Strength | Cost | Best For |

|---|---|---|---|---|

| 316 Stainless Steel | Excellent | Very High | High | Saltwater, offshore, and brackish environments |

| Galvanized Steel | Good | High | Medium | All-around use, both freshwater and saltwater |

| Aluminum | Very Good | Medium | Low-Medium | Freshwater, smaller boats, and weight-sensitive setups |

Beyond just the raw material, always take a close look at the construction quality. Smooth, polished welds and clean edges aren't just for looks. They are critical for preventing chafe on your anchor rode, protecting your expensive line from premature wear and tear that could lead to failure.

Installing Your Anchor Bracket for Maximum Strength

A perfectly chosen anchor bracket is only half the battle. If it's not installed correctly, it’s just a shiny piece of metal. Think of it like the foundation of a house—everything else depends on it being solid. A proper installation turns that bracket from a simple accessory into a rock-solid part of your boat's safety system, ready to take on the massive forces of anchoring.

The job might seem a little daunting at first, but if you break it down into simple, clear steps, any boat owner can handle it. It all comes down to careful prep work, drilling precise holes, and using the right stuff to create a bond that's as tough as your hull. Get this part right, and you'll be able to drop anchor with total confidence, season after season.

Gearing Up for a Solid Installation

Before you even think about drilling a hole, you need to get all your tools and materials lined up. Having everything ready to go saves you from those frustrating trips back to the garage and keeps the project moving smoothly.

Here’s what you'll want to have on hand:

- Safety Gear: Don't even start without safety glasses and a good pair of gloves.

- Drill and Bits: A quality power drill is a must, along with sharp, marine-grade cobalt or titanium bits that match your bolt size.

- Measuring Tools: You'll need a tape measure, a pencil, and a center punch to mark your drill spots so the bit doesn't wander.

- Wrenches and Sockets: A good set is essential for tightening everything down securely.

- Marine-Grade Sealant: This is critical. A high-strength adhesive sealant like our Marine Sealant creates a completely watertight seal.

This visual guide breaks down why different materials matter, especially when it comes to strength and fighting off corrosion.

As you can see, stainless steel really hits the sweet spot with its blend of strength and rust resistance, making it a fantastic choice for a long-lasting, reliable installation.

The Installation Process Step-by-Step

1. Find the Perfect Spot: Place the bracket on your bow, making sure it’s lined up with the centerline of the boat. You want a clear, straight path for the anchor to drop without banging into anything. Before you mark anything, take a peek below deck to make sure you won't be drilling into any wires, supports, or other obstructions.

2. Drill with Confidence: Once you've marked your holes, use a center punch to make a small indent at each mark. This gives your drill bit a starting point and stops it from skittering across your gelcoat. It’s always a good idea to drill smaller pilot holes first, then step up to the final bit size for a clean, precise hole.

3. Seal for a Watertight Bond: This is a step you can't skip. Apply a generous bead of a tough, marine-grade sealant like 3M 5200 around each hole and on the bottom of the bracket itself. This is what keeps water from seeping into your boat's core and causing major headaches down the road. If you think you might ever need to remove the bracket, you can learn the differences between 3M 5200 and 4200 to pick the right sealant for the job.

4. The Non-Negotiable Backing Plate: Honestly, this is the most important step of all. Before you put the nuts on the bolts, you must place a backing plate on the underside of the deck. This is usually a thick piece of stainless steel or aluminum that spreads the massive anchoring load over a much wider area. Without it, you risk stress cracks or even ripping the bracket right out of the deck. Tighten the bolts down evenly and securely.

Essential Maintenance for a Reliable Anchoring System

Think of your anchor bracket as a frontline soldier. It's constantly battling corrosive saltwater, punishing UV rays, and the immense physical stress of holding your boat steady. Just like any other piece of critical safety gear, it needs regular attention to do its job when you need it most. Letting maintenance slide is like ignoring a fraying rope—it's only a matter of time before it fails, and always at the worst possible moment.

The best defense against failure is a simple, consistent maintenance routine. Treat it like a quick pre-flight check you do before leaving the dock. This proactive mindset keeps every part of your anchoring system ready for action and stops small issues from blowing up into trip-ending disasters.

Your Quick Maintenance Checklist

Making these checks a regular habit only takes a few minutes, but it can save you from a world of headaches down the road.

-

Rinse with Fresh Water: After every single trip in saltwater, give your anchor bracket a good, thorough rinse with fresh water. This is the #1 most effective thing you can do to fight off salt buildup, which is the primary cause of corrosion.

-

Inspect Fasteners and Welds: Everything on a boat vibrates loose eventually. Get in the habit of checking all the nuts, bolts, and mounting screws to make sure they're still tight. Give the welds a quick visual inspection for any signs of stress cracks or fatigue, especially if you've recently anchored in rough weather.

-

Check the Roller: Your roller needs to spin freely and smoothly. If it feels stiff or has seized up completely, clean out any sand, salt, or other gunk that's gotten trapped. A quick shot of marine-grade lubricant will keep it moving effortlessly and reduce wear and tear on your anchor rode.

Of course, a reliable system is about more than just hardware. Knowing how to secure your anchor line is just as critical as having tight bolts. It's worth taking the time to master the art of tying essential boat knots so you're always prepared.

A well-maintained anchor bracket is the bedrock of a safe anchoring experience. It's the one connection point that bears the entire load of your boat against wind and current, so its integrity is absolutely non-negotiable.

To see how all the pieces fit together, check out our detailed guide to the complete boat anchor system. Taking a holistic approach to maintenance is what creates a truly dependable safety net for your vessel.

Solving Common Anchor Bracket Problems

Even the best marine hardware takes a beating. Between constant vibration, saltwater spray, and heavy loads, it's no surprise that your anchor bracket can start showing signs of wear and tear. The trick is to catch these little issues before they become big, trip-ruining headaches.

A wobbly or loose bracket is usually the first red flag. Think about it—the vibrations from your engine and the constant push and pull of waves can work mounting bolts loose over time. Before you head out, make it a habit to physically grab the bracket and give it a good shake. If you feel any give, it’s time to break out the toolbox.

Quick Fixes for Common Issues

Most of the time, you can solve these problems with a few basic tools and a little bit of know-how. Here’s a rundown of the most common complaints we hear about boat anchor brackets and how to handle them.

- The Problem: A Loose or Wobbly Bracket. Nine times out of ten, this is just loosened mounting bolts and nuts. Grab a wrench and socket set and tighten them down until they’re snug. If you find they keep loosening up trip after trip, consider adding a dab of thread-locking compound for some extra peace of mind.

- The Problem: The Roller is Seized or Stiff. Salt, sand, and general gunk are the usual suspects here. Give the roller a good, thorough rinse with fresh water. You might need a stiff brush to really get in there and knock out any stubborn debris. A quick shot of marine-grade lubricant will have it spinning like new again.

- The Problem: Grinding or Squeaking Noises. That sound is the universal sign of friction. It could be that stiff roller we just talked about, or your anchor rode might be rubbing against the side of the bracket. Check the roller first. If it's spinning freely, take a look at how your anchor line is sitting to make sure it's properly aligned.

A few minutes of regular checks will keep your whole anchoring system quiet, safe, and ready for action. Trust me, a little prevention on the dock goes a long way toward a stress-free day on the water.

Frequently Asked Questions About Anchor Brackets

When you're sorting through the details of anchor brackets for boats, a few common questions always seem to pop up. Getting these sorted out is key to making sure your anchoring system is safe, secure, and built to last.

Do I Really Need a Backing Plate?

Yes. 100% yes. Think of a backing plate as a non-negotiable part of the deal. It's a simple piece of metal or marine-grade plywood that sits under the deck, spreading the massive pulling force of your anchor over a much wider area.

Without one, all that strain is focused on a few small bolt holes. That’s a recipe for gelcoat cracks or, even worse, a catastrophic failure where the anchor rips a chunk right out of your deck.

How Do I Choose the Right Size Bracket?

Picking the right size bracket boils down to three things: your anchor's size and weight, the diameter of your anchor line or chain (your rode), and the amount of real estate you have available on your bow.

Your bracket needs to be wide enough to accommodate the anchor's shank, and the roller has to be a good fit for your rode. Always, always check the manufacturer’s specs for the bracket’s maximum recommended anchor weight. You need to know it can handle the load.

The bracket is the foundation of your entire anchoring system. Just like you wouldn't build a house on a shaky foundation, you don't want to trust your boat to an undersized bracket. Getting the size right and using a backing plate makes that foundation rock-solid.

Can I Install a Bracket on a Dinghy?

You bet. There are specialized anchor brackets designed specifically for inflatable boats and dinghies. Instead of bolts that would puncture the tubes, these are usually mounted to the bow with a seriously strong, marine-grade adhesive.

These brackets are typically made from durable PVC or composite materials to keep the anchor line from chafing and damaging the inflatable tubes. The key is to find a kit made for inflatables so you get the right bracket material and the proper adhesive for a bond that won't let go.

For a complete anchoring setup you can rely on, from the bracket all the way to the rope, Better Boat has the premium, tested gear to keep you secure on the water. Check out our full line of anchoring and docking solutions at https://www.betterboat.com.