Best Boat Polish for Oxidation Your Guide to a Flawless Hull

When you're trying to figure out the best boat polish for oxidation, it's not about finding one magic bottle. The right product is simply the one with the correct level of abrasiveness for the job at hand.

If you're dealing with heavy, chalky buildup, you'll need a heavy-duty rubbing compound to cut through that damaged top layer. On the other hand, if you're just seeing some light hazing, a much gentler fine-finishing marine polish will likely do the trick.

The secret is to diagnose the damage first, then start with the least aggressive product that can still get the job done. This approach saves your gelcoat and saves you a ton of work.

Your Guide to Beating Gelcoat Oxidation

That chalky, faded haze creeping across your boat's hull is an all-too-common enemy for every boat owner: gelcoat oxidation. It’s the result of a relentless assault from UV rays, salt, and moisture that breaks down the gelcoat's polymers. Your once-glossy finish turns into a dull, powdery surface that looks tired and neglected.

If you let it go, it’s not just an eyesore. The gelcoat becomes more porous, making it a magnet for stains and grime.

But here’s the good news: restoring that deep, factory shine is completely doable. The process involves carefully removing that thin, damaged top layer to reveal the fresh, vibrant gelcoat hiding underneath.

This isn't just a simple wipe-on, wipe-off task, though. It requires picking the right tool for your specific level of oxidation. Choosing the wrong one can either be totally ineffective or, worse, be way too aggressive and create even more work for you.

Understanding the Restoration Process

Think of it like refinishing a piece of wood. You wouldn't start with fine-grit sandpaper on a rough, weathered plank, right? You start coarse to strip away the damage and then move to finer grits to smooth and polish the surface to a high gloss.

Boat polishes and compounds work the exact same way, just with microscopic abrasives.

- Rubbing Compounds: These are your heavy hitters. They’re the most aggressive products, designed to tackle heavy oxidation with larger abrasives that "cut" away the dead gelcoat quickly.

- Polishes: A step down in aggressiveness, polishes use finer abrasives. They're perfect for removing light oxidation and swirl marks, or for refining the surface after you've used a compound.

- Waxes & Sealants: These have little to no cutting power. Their one and only job is to protect your beautifully restored finish from future UV damage and the elements.

Choosing the best boat polish for oxidation isn't about cleaning the surface—it's a minor resurfacing project. The goal is always to remove as little gelcoat as absolutely necessary to bring back that deep color and shine.

The need for good solutions is growing right alongside the boating community. The global boat polish market hit USD 145 million in 2024 and is expected to keep climbing, fueled by a boom in recreational boating.

With fiberglass hulls making up 65% of polish applications, knowing how to fight oxidation is more critical than ever for protecting your investment. You can see more on market growth from a recent DataHorizzon Research report.

If you want to dive deeper, our comprehensive guide on selecting the right boat oxidation remover breaks down exactly how to diagnose your hull's condition. Getting this first step right is the key to a flawless finish.

Diagnosing the Damage: How Bad Is the Oxidation?

Before you can even think about which polish to buy, you've got to play detective. Picking the wrong product is like using a garden hose to put out a bonfire or a fire truck to water a houseplant—it's just the wrong tool for the job. Honestly, figuring out just how bad the oxidation is on your hull is the single most important step in this whole process.

This one diagnosis will tell you exactly how abrasive your polish or compound needs to be. Get it right, and you’ll save yourself a ton of time, money, and your boat's precious gelcoat. Get it wrong, and you could blow an entire weekend of hard work with nothing to show for it, or worse, use something so aggressive it damages the finish.

Your boat's gelcoat is that protective outer skin, and knowing its condition is everything. To get a better handle on this crucial surface, take a look at our guide on what gelcoat is and why it matters.

The Simple Swipe Test

You don’t need any fancy gear to figure this out. All it takes is a clean, dark-colored microfiber towel and a few seconds of your time.

Go find a spot on the hull that looks the most faded or chalky. Give it a firm wipe with the cloth, covering about a square foot. Now, take a good look at that cloth. The amount of colored residue clinging to it tells you everything you need to know.

Classifying the Severity of Oxidation

Oxidation generally falls into one of three buckets, and each one demands a different battle plan. Your swipe test is about to tell you exactly where your boat stands.

1. Light Oxidation

- What it Looks Like: Your hull has just started to lose its gloss. It might look a little hazy or cloudy, something you notice most in direct sunlight.

- What it Feels Like: The surface is still pretty smooth to the touch.

- Swipe Test Result: Your dark cloth shows a very light, faint dusting of colored residue. It's minimal—just enough to confirm the top layer is beginning to break down.

This is the easy stuff. You’ve caught the problem early, and a gentle marine polish or a good one-step cleaner wax is usually all it takes to cut through the haze and bring back that shine.

2. Moderate Oxidation

- What it Looks Like: The color is now noticeably dull and faded out. There’s a definite chalky or powdery film on the surface.

- What it Feels Like: Run your hand across it. You'll feel a slightly rough, almost gritty texture.

- Swipe Test Result: The cloth comes away with a thick, obvious layer of colored chalk. The residue is dense and impossible to miss, which signals significant surface decay.

At this point, a simple cleaner wax just isn't going to cut it. You’ll need to step up to a dedicated marine polish formulated with fine-to-medium abrasives to effectively grind away that damaged layer of gelcoat.

3. Severe Oxidation

- What it Looks Like: The hull's original color is almost completely hidden under a thick, white, powdery layer. The finish looks totally flat and dead.

- What it Feels Like: The surface feels extremely rough and porous, almost like you’re touching fine-grit sandpaper.

- Swipe Test Result: A single wipe will completely coat your cloth in a heavy, chalky powder. It’ll look like you just erased a dusty chalkboard.

This level of damage requires the heavy artillery. You’ll need to start with an aggressive rubbing compound designed to power through that thick, dead gelcoat. Only after that can you move on to finer polishes to restore the gloss. Trying to fix this with a light polish would be a complete and frustrating waste of time.

Choosing Your Tools: Compounds, Polishes, and Waxes

Walking down the boat care aisle can be dizzying. You're hit with a wall of compounds, polishes, and waxes, all promising a showroom shine. Here’s the secret: each one has a specific job, and it all comes down to its "cutting" power, or how abrasive it is. Think of it as a journey from aggressive surface correction to fine-tuning the gloss and, finally, locking it all in with protection.

Picking the right product is about more than just a good-looking finish; it’s about protecting your gelcoat for the long haul. If you go too aggressive on light oxidation, you're sanding away healthy gelcoat for no reason. On the other hand, trying to fix heavy, chalky oxidation with a gentle polish will just leave your arms sore and your boat still looking sad.

This isn't a niche problem. The market for products that fight oxidation on fiberglass hulls is expected to hit $400 million globally by 2028. With the average boat on the water being about 15 years old, having the right polish in your toolkit is more important than ever for keeping these older vessels looking their best.

To make sense of it all, let's break down the product types and when you'll need them.

The Product Abrasiveness Guide

I've put together a quick guide to help you visualize where each product fits into the restoration process. Think of it as starting with the most aggressive product necessary for the job and working your way down to the final protective layer.

| Product Type | Abrasiveness Level | Best For | Application Method |

|---|---|---|---|

| Rubbing Compound | High | Severe, chalky oxidation and deep scratches | Rotary or DA Polisher |

| Marine Polish | Medium to Low | Moderate to light oxidation, swirl marks | Rotary or DA Polisher, Hand Application |

| Cleaner Wax | Very Low | Very light oxidation, cleaning, and protecting in one step | DA Polisher or Hand Application |

| Wax / Sealant | None | Protecting a freshly polished surface from UV damage | Hand Application or DA Polisher |

As you can see, it's a step-down process. You only use the "heavy hitters" when absolutely necessary, then refine the finish before sealing it all up.

The Heavy Hitters: Rubbing Compounds

When you’re dealing with a bad case of oxidation—that thick, chalky film you found during your swipe test—it's time to call in the big guns. A rubbing compound is what you need. These products are packed with aggressive abrasives designed to do one thing: cut through that dead, oxidized layer of gelcoat to reveal the good stuff underneath.

Our Heavy Cut Compound is built for this exact scenario. It's the essential first step for any hull that's been neglected. Don't even think about trying to fix severe oxidation with a mild polish; you'll just be wasting your time and energy.

The Refiners: Marine Polishes

After the compound has done the heavy lifting, it's time to refine the surface. Or, if you're lucky enough to be starting with just moderate oxidation, this is where you'll begin. Marine polishes have much finer abrasives than compounds. Their job is to erase the tiny scratches and haze left by the compounding stage and bring out that deep, wet-looking gloss.

If your boat has just lost its luster but isn't chalky, a quality polish might be all you need. Our Marine Polish is the perfect follow-up to our compound, but it’s also a fantastic standalone solution for boats that need a serious shine boost. For a deeper dive on this, check out our guide on the best boat polishing compounds available.

Pro Tip: Don't ever skip the polish step after using a heavy-cut compound. Compounding brings the color back, but it leaves the finish looking dull. Polishing is what creates that brilliant, mirror-like shine you’re after.

The Protectors: Waxes and Sealants

You've done the hard work of cutting and polishing, and now for the most important step: protection. Waxes and sealants contain virtually zero abrasives. Their only mission is to lay down a tough, protective barrier over your beautifully restored gelcoat. This is the shield that will fight off the UV rays and salt spray that caused the oxidation to begin with.

Think of a good marine wax as sunscreen for your boat. It blocks UV, makes water bead up and roll off, and keeps dirt from sticking, which makes your next wash-down a whole lot easier.

Our Better Boat Marine Wax is designed to provide this critical protective layer, sealing in that shine and stopping future damage in its tracks. If you skip this step, all your hard work will be undone in a matter of months as the oxidation creeps back in.

This three-part system—compound, polish, wax—is the proven path to a full restoration. Match the product to the problem, and you'll get a professional-grade finish that doesn't just look amazing but also protects your investment for seasons to come.

Your Complete Gelcoat Restoration Workflow

So, you've figured out how bad the oxidation is and have your tools ready to go. Now for the fun part: bringing that gelcoat back to life. This isn't just about reading steps; this is the real, on-deck process for turning a chalky, tired-looking hull into one that gleams like it just left the showroom.

I like to think of this as a restoration project, not a chore. Each stage builds on the one before it, methodically stripping away the damage and revealing that deep, rich gloss underneath. Follow a solid plan, and you'll get professional results without the guesswork.

Prepping The Hull For Success

Before a polisher even gets near your boat, you have to give it a serious wash. Trying to polish a dirty hull is a classic rookie mistake. All you'll do is grind salt, dirt, and whatever else is on there right into the gelcoat, creating a whole new set of scratches and swirls. A clean surface is everything.

Grab a good marine boat soap, like our pH Neutral Boat Soap, and a soft wash mitt. Wash the entire area you plan to work on, starting from the top and working your way down. You'll want to pay extra attention to the waterline, since that's where grime loves to collect.

Once it's washed, give the hull a thorough rinse with fresh water and dry it completely with clean microfiber towels. Now, take a few minutes to tape off everything you don't want the compound to touch. This includes:

- Trim and decals: Masking tape is your best friend here. It'll protect them from getting scuffed by the polisher or stained by the compound.

- Hardware and through-hulls: Cover up any stainless steel or plastic fittings to keep them clean.

- Non-skid surfaces: You do not want polish residue getting into those textured decks. It’s a real pain to get out.

This prep might feel a bit tedious, but trust me, it saves a ton of cleanup time later and protects all the other parts of your boat.

Mastering Application Techniques

How you apply the product is just as critical as which product you choose. You’ve basically got two options: doing it by hand or using a machine. While you can get by with hand application for a tiny spot repair, a machine is pretty much non-negotiable for getting that uniform, high-gloss finish across an entire hull.

For both first-timers and seasoned pros, the best tool for this job is a dual-action (DA) orbital polisher. It's much safer than a high-speed rotary buffer, which can burn right through your gelcoat in a heartbeat if you don't know exactly what you're doing. A DA polisher oscillates randomly, which dramatically cuts down the risk of creating swirl marks or holograms. It's just a much more forgiving machine.

A dual-action polisher is your best friend in this process. Its random orbital motion mimics the movement of your hand but with far more speed and consistency, delivering professional results without the high risk of a rotary buffer.

The Art Of The Buffing Process

Alright, this is the main event. The trick to a flawless finish is to work in small, manageable sections—think about 2x2 feet at a time. This lets you really focus your effort and keeps the compound from drying out before you've had a chance to properly work it into the surface.

For each little section, here’s the rhythm:

- Apply Product to the Pad: Squeeze four or five pea-sized dots of your compound or polish onto the pad.

- Spread the Product: With the machine off, just dab the pad around the gelcoat section to get the product distributed.

- Work the Polish: Turn the polisher on its lowest speed and make a pass or two to spread it out more. Then, crank up the speed and work the area in a cross-hatch pattern—overlapping passes up-and-down, then side-to-side. Use firm, even pressure.

- Wipe and Inspect: You'll see the product start to break down and turn translucent. When it does, ease up on the pressure for one last pass. Turn the polisher off, and wipe the residue away with a fresh microfiber towel.

The pad you choose makes a huge difference. For heavy, chalky oxidation, start with a wool or microfiber cutting pad. For more moderate issues or when you move on to the polishing stage, a foam polishing pad is perfect.

Inspecting Your Work And Applying Protection

After you finish a section, grab a bright light and look at the surface from a few different angles. You're searching for a consistent, deep gloss without any haze, swirls, or leftover dull spots. If you see anything you don't like, don't be afraid to do another pass. It's better to get it right before moving on.

Once the entire hull has been compounded and polished to perfection, you've reached the final—and most critical—step: protection. All that hard work will go to waste if you leave that fresh gelcoat exposed to the sun and salt. If you want a deep dive on the entire process from start to finish, check out our guide on complete boat gelcoat restoration.

Get a high-quality marine wax or sealant and create a tough barrier against UV rays. Our Better Boat Marine Wax is designed specifically for this, sealing the pores of the gelcoat to stop oxidation before it can start again.

Use a clean foam applicator pad to apply it, let it dry to a haze, and then buff it off with a new microfiber towel. That final buff is what brings out that brilliant, lasting shine that will keep your boat looking sharp all season.

Pro Tips for a Flawless Finish

Getting that perfect, mirror-like shine really comes down to the little details—the things seasoned pros never, ever skip. These are the subtle techniques that take a good job and make it a great one, ensuring all your hard work actually lasts. It all starts with a proven workflow.

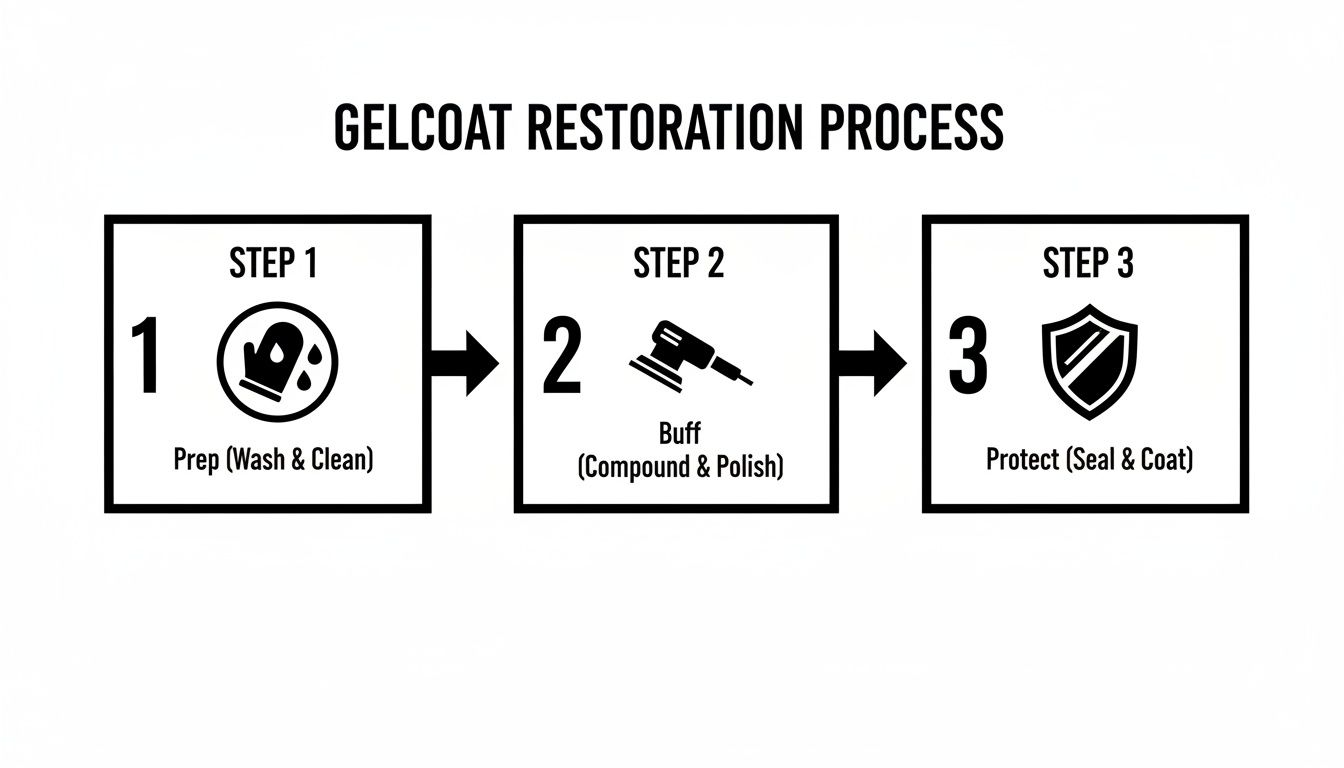

This visual guide breaks down the whole gelcoat restoration process into three simple stages: Prep, Buff, and Protect.

As you can see, a flawless finish isn't just about the buffing. You absolutely need thorough prep work and a tough final layer of protection to lock that shine in.

Work Smart, Not Hard

One of the biggest mistakes I see is people working in direct sunlight on a hot hull. Your polish and compound will dry out almost instantly, turning into a stubborn, cakey mess that's a nightmare to remove.

Always work in the shade or on an overcast day when the gelcoat is cool to the touch. This gives the product the right amount of time to work its magic and achieve maximum gloss.

Here's another pro move: properly "prime" a new polishing pad. Before you even touch it to the hull, apply a few pea-sized dots of your product to the pad, then use your finger to lightly spread it across the face. This simple step ensures you get even coverage from the very first pass and prevents dry buffing, which can easily create nasty micro-scratches.

Master Your Technique

For that uniform, swirl-free finish everyone wants, you have to master the "cross-hatch" pattern. Work your polisher over a small section (think 2'x2') in overlapping passes, first up and down, and then side to side.

This guarantees complete coverage and consistent abrasion across the entire work area, eliminating any blotchy or hazy spots. It’s a simple technique that delivers truly professional results.

Don't underestimate the small stuff. I've seen perfect finishes ruined by cheap microfiber towels that leave behind lint and fine scratches. Invest in high-quality, plush microfiber towels just for wiping off polish residue and buffing wax. It makes a huge difference.

Navigating tricky areas like non-skid decks or around cleats and railings requires a bit more precision. Use painter's tape to protect these areas before you start. For the tight spots where a machine just won't fit, switch to a foam hand applicator pad to make sure every last inch of your hull gets the attention it deserves.

The market for these products shows just how crucial they are. North America's boat polish market shot up to USD 299.59 million in 2023, mostly driven by the need to fight off oxidation from UV rays and saltwater.

Now, with 85% of premium polishes including UV blockers, the focus is clearly on both restoration and long-term prevention. You can dive deeper into these trends with this report from Verified Market Research.

Maintaining Your Shine and Preventing Future Oxidation

You’ve just put in the hard work to restore that showroom gloss, and your boat looks incredible. The last thing you want is for that chalky, faded haze to start creeping back in. Now it’s time to shift from restoration mode to maintenance mode—this is what protects your investment and keeps that shine looking great for seasons, not just a few weeks.

Trust me, a simple and consistent routine is far easier than tackling a massive oxidation removal project every single year.

The secret is all about proactive protection. The sun’s UV rays are absolutely relentless, constantly working to break down your gelcoat. By keeping a durable barrier between the elements and your hull, you can dramatically slow down the oxidation process. It'll save you countless hours of compounding and buffing down the road.

Building a Sustainable Maintenance Routine

The foundation of any good maintenance plan is simply washing your boat regularly. It’s critical to use a pH-neutral marine soap, one that’s made specifically to clean grime without stripping away the protective coatings you’ve just applied.

Using harsh household detergents is a quick way to undo all your hard work, as they’ll just remove the wax and leave your gelcoat vulnerable all over again.

Beyond washing, the single most important habit is applying a fresh coat of high-quality marine wax or sealant. Think of it as sunscreen for your boat. For most boaters, this means waxing every 3-4 months. If your boat lives in a harsh, sunny climate like Florida or Arizona, you might want to do it even more frequently.

Your maintenance schedule is your best defense against future oxidation. A consistent routine of washing and waxing is far less work than a full-scale compounding and polishing job every spring.

This is exactly the kind of durable protection our Better Boat Marine Wax was formulated for. It uses a blend of hard carnauba wax and specialized polymers to create a tough shield against the UV radiation and salt spray that cause oxidation in the first place.

The Impact of Smart Storage

Don't underestimate how much of a difference storage makes. How and where you store your boat plays a massive role in preserving its finish.

Whenever you can, use a boat cover. It provides an incredible layer of defense, blocking direct sunlight, keeping off acid rain, and preventing dirt from settling on the surface where it can trap moisture against the gelcoat.

Proper storage—whether in a covered slip, a garage, or even under a high-quality breathable cover outdoors—can dramatically extend the life of your wax and your boat’s finish. This simple step minimizes your boat’s exposure, which means less time spent on maintenance and more time enjoying the water. This proactive approach is the core of finding the best boat polish for oxidation—by preventing it from starting.

Common Questions About Boat Oxidation

Even with a solid plan, a few questions always seem to pop up during a restoration project. Getting straight answers builds your confidence and makes sure you’re using the right products the right way. Let's tackle some of the most common ones I hear from other boaters.

Can You Use Car Polish on a Boat?

It’s tempting to grab whatever polish you have in the garage, but trust me on this one—it's a bad idea. Polishes made for cars are designed to work on automotive clear coats, which are much harder and way less porous than the gelcoat on your boat. A car polish just doesn't have the teeth to cut through those chalky, oxidized layers.

Marine-specific products are engineered with the right kind of abrasives to handle gelcoat's unique properties. You'll just end up frustrated and wasting a ton of effort if you try to use an automotive product.

How Do You Know When You Have Polished Enough?

This is a great question, and the answer really comes down to feel and a good eye. After you buff a section, wipe all the residue away and look at it under good light. I mean really look at it—from a few different angles.

You're looking for a deep, even gloss. There shouldn't be any leftover haze, dull patches, or swirl marks from the compounding step. Run your hand over the surface; it should feel perfectly smooth. If you still see imperfections, that spot needs another pass. The goal is to get as much clarity and shine as you can before you even think about grabbing your wax.

The key difference between a polish and a compound is aggressiveness. A rubbing compound has coarse abrasives for cutting away heavy oxidation, while a polish uses finer abrasives to refine the surface and restore gloss. You compound to remove damage; you polish to create shine.

Once you have that shine, protecting it is non-negotiable. The best defense is a good offense, so applying a high-quality marine wax every 3-4 months will shield your gelcoat from UV rays and stop oxidation from coming back.

Bringing your boat's finish back to life is one of the most rewarding projects you can do, and having the right system makes all the difference. From heavy-cut compounds to protective waxes, Better Boat offers everything you need to achieve a professional, lasting shine. Explore our complete line of marine care products at Better Boat and keep your vessel looking its absolute best.