A Pro's Guide to Boat Bottom Painting

Let's be honest, painting your boat's bottom is a tough job. It's one of those maintenance tasks that’s easy to put off, but trust me, ignoring it can lead to some serious headaches down the road. This is about so much more than just making your boat look good below the waterline.

Why a Great Bottom Paint Job Matters

A fresh, slick coat of antifouling paint is your hull's first line of defense. It creates a surface that’s incredibly difficult for marine critters like barnacles, algae, and slime to latch onto. Without that protective barrier, your hull basically becomes a welcome mat for all sorts of biofouling.

Performance and Fuel Efficiency

Ever feel like your boat is sluggish or burning through fuel faster than usual? The culprit is often a fouled bottom. All that marine growth creates a surprising amount of drag, forcing your engine to work overtime just to move through the water.

Even a thin layer of slime can spike your fuel consumption by up to 15%. If you've got a serious case of barnacle growth, you could see your top speed plummet and your fuel costs nearly double.

A clean, properly painted bottom lets your boat slice through the water the way it was meant to. You get better speed, sharper handling, and a much friendlier bill at the fuel dock. It's a win-win.

Protecting Your Investment

Beyond just speed and efficiency, bottom painting is fundamental to protecting the hull itself. When marine growth clings to the gelcoat, it traps moisture against the surface. Over time, this can lead to osmosis and those dreaded, painful-to-fix hull blisters.

A proactive approach to bottom painting isn't just maintenance; it's asset protection. By preventing the attachment of marine life, you are actively defending your hull against long-term degradation and preserving its structural integrity and resale value.

Regularly inspecting and repainting your hull is just smart boat ownership. Letting it go can lead to expensive gelcoat repairs or, in a worst-case scenario, structural damage that puts your vessel's safety at risk. A well-kept bottom is a non-negotiable part of any solid boat maintenance checklist.

Environmental Responsibility

Using modern, effective antifouling paint also makes you a more responsible boater. When boats travel between different lakes, rivers, or coastal areas, they can accidentally give a ride to non-native aquatic species clinging to their hulls.

Keeping your bottom clean helps prevent the spread of these invasive species, which can wreak havoc on local ecosystems. Using paints that comply with local environmental regulations ensures you're doing your part to protect the very waterways you love to enjoy. Bottom line: a great paint job is good for your boat and good for the environment.

Choosing the Right Antifouling Paint

Picking the right antifouling paint can feel overwhelming, but it really just boils down to your specific boat, your local waters, and how you use it. Get this choice right, and you’ll keep your hull clean and efficient. It’s one of the most critical steps in any bottom job, so let's cut through the jargon and focus on what actually matters.

The big three factors are water type (salt, fresh, or brackish), how often the boat gets used, and local environmental rules. A boat that sits for weeks in a warm, high-fouling marina in Florida has completely different needs than one that's trailered every weekend for fishing on a freshwater lake.

Understanding the Main Paint Types

Antifouling paints all work by releasing biocides that tell marine critters to find another home, but they go about it in different ways. You'll mainly run into three types: ablative, hard, and hybrid. Each one has its own strengths depending on your situation.

Ablative (Self-Polishing) Paints

Think of these like a bar of soap. Ablative paints slowly wear away as your boat moves through the water, constantly exposing a fresh, potent layer of biocides. This self-polishing action means the paint stays effective as long as there's a layer left on the hull.

- Best For: Most recreational powerboats and sailboats that are used regularly. The movement through the water is what makes it work best. It’s also a fantastic choice if you want to avoid sanding off thick layers of old paint every time you haul out.

- Pros: No heavy paint buildup, which means way less sanding down the road. You can also haul the boat and relaunch it later without the paint losing its punch.

- Cons: Not the best for very fast boats. High speeds can literally wear the paint away too quickly, shortening its lifespan.

Hard Modified Epoxy Paints

These are often called contact leaching paints. They cure into a hard, tough, porous film packed with biocides. The biocides leach out when they come in contact with water, but the paint film itself stays put, eventually leaving behind an inactive shell.

- Best For: Go-fast boats, race boats, or any vessel that's frequently trailered or dry-stored. The surface is durable enough to be scrubbed without wearing away the paint.

- Pros: It’s extremely durable and stands up to abrasion. You can even burnish it (wet-sand with super fine-grit paper) to get a ridiculously smooth, fast finish for racing.

- Cons: That hard, depleted layer has to come off eventually. This means heavy-duty sanding is in your future before you can repaint. They can also lose their effectiveness if they sit out of the water for too long.

Choosing the right paint is a crucial step for any boater. To make it a bit easier, here’s a quick rundown of the main antifouling paint types and how they stack up against each other.

Antifouling Paint Comparison Chart

| Paint Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Ablative (Self-Polishing) | Wears away slowly over time, continuously exposing fresh biocide. | Most recreational boats used regularly. | No paint buildup, less prep for next time, can be hauled & relaunched. | Can wear too quickly on very fast boats. |

| Hard Modified Epoxy | Biocides leach out from a hard, porous film that doesn't wear away. | Fast boats, race boats, trailered boats. | Very durable, scrubbable, can be burnished for a racing finish. | Requires heavy sanding to remove old layers, loses potency out of water. |

| Hybrid | Combines ablative and hard paint characteristics for a semi-hard finish. | A good all-around choice for many boat types and uses. | Controlled polishing, durable finish, multi-season protection. | Can be more expensive than other types. |

Ultimately, the chart highlights that your boating habits—how fast you go, how often you use your boat, and where you keep it—are the biggest factors in making the right choice.

The Importance of Paint Compatibility

One of the easiest ways to ruin a bottom job is to slap on a new paint that's not compatible with the old one. If you put a hard paint over a soft ablative, it's guaranteed to fail. The new layer will flake right off, and all your hard work will be for nothing.

Pro Tip: Before you even think about buying new paint, you have to figure out what's on your hull right now. The old-school trick still works best: soak a rag in a strong solvent like acetone and rub a small spot on the hull. If the paint gets soft or gummy and comes off on the rag, it's almost certainly an ablative. If the solvent just dulls the finish and nothing really transfers, you've probably got a hard paint.

Knowing this is non-negotiable. If you can't tell for sure, or if you want to switch from one type to another, your safest bet is to apply a barrier coat primer first. This will create a stable foundation for the new paint to stick to.

For aluminum boats, this is even more critical. Standard copper-based paints will eat right through an aluminum hull due to galvanic corrosion. If you've got an aluminum boat, you need a different approach and specific products. Check out our detailed guide on how to repaint an aluminum boat for the full rundown.

This isn’t just a concern for weekend boaters; it’s a massive global industry. The marine antifouling coatings market was valued at over $2.6 billion in 2025 and is expected to hit $5.4 billion by 2035. That growth is fueled by commercial shipping fleets needing to squeeze every drop of fuel efficiency and comply with strict rules to stop the spread of invasive species. You can read more about the booming antifouling coatings market on Research Nester.

At the end of the day, picking the right paint is about being honest about your boating life. If you're in a high-growth zone like the Florida Keys or the Chesapeake Bay, a high-copper ablative is probably your best bet for tough, multi-season protection. On the other hand, if you're on an inland lake with tight environmental regulations, you'll need to go with a copper-free, eco-friendly paint.

Your Essential Tools and Safety Gear

Trying to paint your boat’s bottom without the right gear is a recipe for frustration. You might get it done, but the results will speak for themselves—and not in a good way. Taking the time to gather the right tools and, even more critically, the proper safety equipment will make all the difference between a messy ordeal and a professional-grade finish.

Let's be honest: the success of a bottom job is decided long before you even crack open a can of paint. Having everything you need on hand means you can focus on the task, not on frantic trips back to the hardware store for a different scraper or the right grit of sandpaper.

Your Boat Painting Toolkit

Your tool list can be split into two main buckets: prep gear and application gear. You’ll spend most of your time and effort on the prep work, so don't cut corners here.

- Scrapers: You'll want an assortment. A long-handled scraper is great for knocking down large, flaky areas, but you’ll absolutely need smaller, more detailed scrapers for the tricky spots around thru-hulls, transducers, and struts.

- Sanders: A random orbital sander is your best friend for this job. Make sure you have plenty of 80-grit sandpaper discs on hand. This is the perfect grit to scuff up the old paint, giving the new coat a solid mechanical bond to grab onto.

- Painter’s Tape: Don't cheap out. Get high-quality marine painter’s tape to mask off your waterline. The cheap stuff will bleed, leaving you with a fuzzy, unprofessional edge that's a real pain to fix.

- Rollers and Brushes: Standard household roller covers will literally disintegrate when they touch aggressive bottom paint. You need solvent-resistant roller covers. A 3/16” or 1/4” nap is ideal for laying down a smooth, even coat. Also, keep a couple of quality chip brushes for cutting in around tight areas.

- Mixing Tools: A simple drill-mounted mixing paddle is all you need to get your paint properly blended. This ensures the color is uniform and, more importantly, that the antifouling agents are evenly distributed.

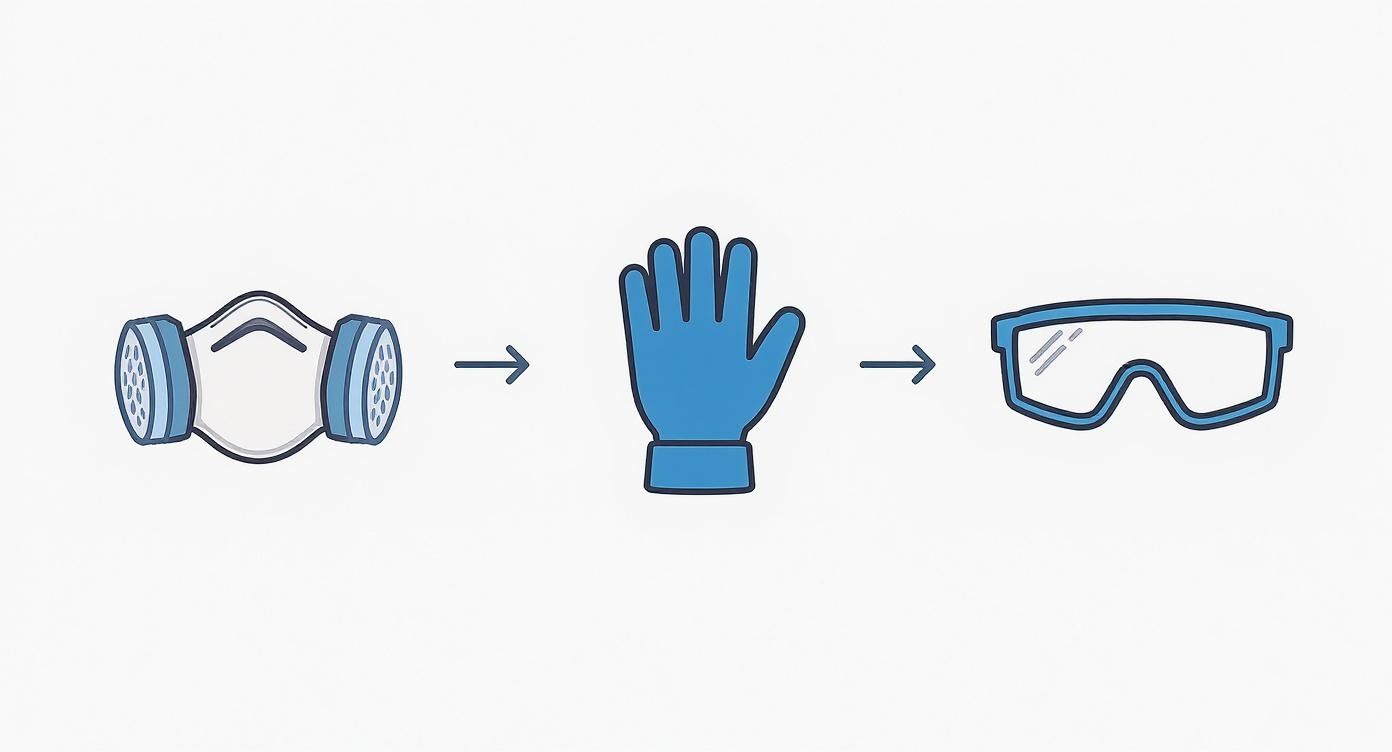

Non-Negotiable Safety Equipment

Listen up, because this is the most important part. Working with antifouling paints and sanding off old layers is serious business. This stuff is loaded with biocides and other chemicals that you do not want to inhale or get on your skin. Protecting yourself isn't just a good idea—it's mandatory.

Safety isn’t just a recommendation; it's a requirement for a successful and healthy boat bottom painting project. The dust and fumes generated can have long-term health effects if you are not properly protected.

A P3 filtered half mask respirator is absolutely critical for protecting your lungs from toxic paint fumes and sanding dust. This, along with a few other key items, should be the first things you buy.

Your essential Personal Protective Equipment (PPE) list includes:

- Respirator: A dual-cartridge respirator rated for organic vapors is what you need. Don't settle for a simple dust mask.

- Eye Protection: Forget basic safety glasses. You want full-seal safety goggles to keep the fine, nasty dust particles out of your eyes.

- Gloves: Chemical-resistant nitrile or butyl rubber gloves are essential. Latex won't cut it.

- Coveralls: A disposable coverall with a hood is the best way to keep paint and toxic dust off your skin and clothes.

This gear is just the start of staying safe around your boat. For a complete look at what you should always have on hand, check out our full https://betterboat.com/blogs/news/boat-safety-equipment-checklist. Getting your tools and safety gear sorted out first sets the stage for a job you can be proud of.

Mastering Hull Prep for a Flawless Finish

This is where the real work happens. It’s the part of the job that separates a decent bottom paint job from a great one. You'll hear old-timers say a perfect paint finish is 90% preparation and only 10% application, and they're absolutely right.

Rushing through prep is the single biggest mistake you can make. Even the most expensive, high-tech antifouling paint on the market will fail if you slap it onto a dirty, unprepared surface. Let’s walk through how to build that flawless foundation.

The Critical First Clean

Before you even think about picking up a sander, that hull needs a deep, thorough cleaning. Your mission is to get rid of every last bit of marine growth, slime, dirt, and especially any wax or grease. These things are the sworn enemies of good paint adhesion.

Kick things off with a solid pressure washing. Work your way from the top down, using a wider nozzle to blast away the loose stuff without gouging the gelcoat. For the stubborn slime lines and oily film that always seem to linger, you'll need to step up your game. A good heavy-duty marine cleaner is your best friend here. Follow the directions on the bottle and give the hull a good scrub with a stiff brush to lift anything the pressure washer missed.

Once you’re done scrubbing, give the hull one last, comprehensive rinse. Just like any paint job, the secret to long-lasting exterior paint lies in proper preparation, and this initial clean sets the stage for everything else.

This infographic is a great visual guide for the safety gear you'll need, starting with the most important one: respiratory protection.

Think of this as a quick checklist for the non-negotiable personal protective equipment (PPE) that will keep you safe from nasty dust and fumes during prep.

Dealing with Old Paint

After the hull is squeaky clean and bone dry, it's time to take a hard look at the old paint. What you do next depends entirely on the condition it's in.

-

Good Condition (Recoating): If the current paint is still holding on strong with no major chipping or flaking, you're in luck. Your job is simply to scuff-sand the entire surface. Grab some 80-grit sandpaper and a random orbital sander. The goal isn't to remove the paint, but to create a rough "profile" that gives the new coat something to bite into. When you're done, wipe the hull down with a solvent wash to get rid of all that dust.

-

Poor Condition (Stripping): Is the old paint flaking, cracking, or built up into thick, ugly layers? It's all got to go. Sanding it all off down to the gelcoat is the most common approach, but be warned—it's a tough, dusty, labor-intensive job. Chemical strippers are another route, though they can be incredibly messy and require very careful handling and cleanup.

No matter if you're scuffing or stripping, the key is consistency. Every single square inch of the hull below the waterline needs to be properly abraded. This ensures the new paint will form a uniform, lasting bond.

For a deeper look at cleaning methods, check out our guide on how to clean a boat bottom. It’s packed with extra tips.

Repairing Hull Imperfections

With the hull sanded and wiped clean, you’ve got the perfect canvas to spot any dings, deep scratches, or the dreaded gelcoat blisters. They might seem like minor flaws now, but painting over them will only make them stand out more and can weaken the finish over time.

Gelcoat blisters are those little bubbles that pop up when water gets under the gelcoat. You have to fix them before you paint. Here’s how:

- Open the Blister: Use a scraper or even a Dremel tool to carefully grind out the blister and expose the void underneath.

- Clean and Dry: This is critical. Thoroughly clean the cavity with acetone and let it dry completely. Trapping any moisture in there will just cause the blister to come right back.

- Fill the Void: Mix up a small batch of a quality, waterproof marine epoxy filler. Our Epoxy Repair Kits are designed for exactly this, creating a permanent, rock-solid bond.

- Fair the Surface: Overfill the repair just a little bit. Once the epoxy has cured hard, sand it down with 80-grit paper until it's perfectly fair and flush with the rest of the hull.

You can use this exact same process for any deep scratches or gouges you find. The goal here is a perfectly smooth, fair surface. Any bumps or hollows you leave will be magnified tenfold once you put a fresh coat of glossy paint on. Trust me, taking the time to do these small repairs pays off big time in the final look.

Applying Primer and Paint Like a Pro

With a perfectly prepped, clean, and faired hull, you’ve officially done the heavy lifting. Now for the satisfying part: laying down the coatings that will protect your boat for the entire season. This is the moment all that sanding and cleaning pays off, turning your hard work into a tough, professional-grade finish.

But it’s not just about slapping on some color. You're building a complete protective system, and every good system starts with the right foundation. For most boats, especially those with any exposed fiberglass or gelcoat, that foundation is a barrier coat primer. This step is what creates an impermeable shield against water absorption and those dreaded hull blisters.

The Crucial Role of a Barrier Coat

Think of a barrier coat as the ultimate defender for your hull. It's usually a two-part epoxy that cures into a rock-solid, waterproof layer. If you've sanded down to bare fiberglass or just finished a bunch of blister repairs, this isn't optional—it's essential.

Without it, water can slowly creep into the porous gelcoat, leading to osmotic blistering. Applying a good barrier coat is the best insurance policy you can buy against having to do those same repairs in a few years. It also gives your antifouling paint a perfect, uniform surface to grab onto, which means a stronger bond and a longer life for your topcoat.

Calculating Your Paint Needs

Before you crack open a can, you need to know exactly how much paint to buy. Getting too much is a waste of money, but running short mid-job is a nightmare. Thankfully, there’s a straightforward formula to get a solid estimate.

First, figure out your hull's approximate underwater surface area:

Length Overall (LOA) x Beam x 0.85 = Approx. Square Footage

So, for a 30-foot boat with a 10-foot beam, you're looking at roughly 255 square feet of surface area below the waterline (30 x 10 x 0.85).

Next, just look at the paint can. Every manufacturer lists a "theoretical coverage" in square feet per gallon. If your paint covers 400 sq. ft. per gallon, our 255 sq. ft. hull would need a bit over half a gallon for one coat. Since you'll almost always be applying two coats, grabbing two gallons is a safe bet and leaves you with a little extra for touch-ups.

Techniques for a Smooth Finish

Whether you're using a brush, a roller, or a combination of both, the goal is always a smooth, even coat without drips, runs, or "holidays"—those annoying missed spots. For a finish that looks almost sprayed-on without the sprayer, the classic "roll and tip" method is king.

Here’s how it’s done:

- Mix It Right: Bottom paint is packed with heavy solids (like copper) that settle into a dense sludge at the bottom. You must use a drill-mounted mixing paddle for at least five minutes to get everything fully suspended.

- Cut In First: Grab a chip brush and paint around all the tricky spots first—think transducers, struts, thru-hulls, and right along your painter's tape at the waterline.

- Roll It On: Load up a solvent-resistant roller with a 1/4" nap and apply the paint in a manageable 3x3 foot section. Let the roller do the work; don't push too hard. The goal is a consistent, wet film.

- Tip It Off: Right after rolling a section, take a clean brush, hold it at a low angle, and lightly drag it across the wet paint with vertical strokes. This simple move knocks down the roller texture, smooths the surface, and pops any bubbles.

The real secret is maintaining a "wet edge." Always tip off into the section you just rolled. This prevents ugly lap marks where the paint has started to dry. Work in sections and keep a steady pace to ensure everything blends together perfectly.

This whole process is a big deal in a growing market. The global boat bottom paint industry was valued at around $2.5 billion in 2023 and is projected to hit $3.2 billion by 2028. This boom is fueled by the ever-increasing number of recreational boats, which account for about 60% of the market. You can dig into the numbers in this boat bottom paint market analysis on marketreportanalytics.com.

Respecting Dry Times

The last and most important step is simply patience. Every paint can specifies the minimum drying times you need to wait between coats and—most critically—before launching the boat. Rushing this will ruin the paint's ability to cure correctly, kneecapping its antifouling power and lifespan.

Read the can and follow the manufacturer's instructions to the letter. Remember that temperature and humidity play a huge role in cure times, so adjust your schedule if it's cool or damp. Giving your new paint job the full time it needs to harden up is the final step that makes all your prep work worthwhile.

Keeping Your New Paint Job Performing

Just because your boat is back in the water doesn't mean the work is done. To really get your money's worth out of that fresh bottom paint, you need a smart, simple maintenance plan. This will extend its life and keep your hull performing at its best all season long.

The cornerstone of this plan is regular, gentle cleaning. Once you start to see a light layer of slime forming, a quick wipe-down with a soft cloth or a non-abrasive hull cleaning pad is usually all it takes. This is absolutely critical for ablative paints, since hard scrubbing will literally wear away the protective layer you just worked so hard to apply.

Create a Simple Inspection Schedule

You don't need to be a marine surveyor to spot trouble before it gets out of hand. A quick check once a month can save you from some major headaches down the line.

- Check the Waterline: This area gets hit the hardest by sun, water, and growth. Keep an eye out for any signs that the paint is thinning out or starting to flake.

- Inspect High-Flow Areas: Give a little extra attention to the leading edges of your keel, rudder, and bow. Water friction is relentless here and can cause the paint to wear away much faster.

- Look for New Growth: If you start spotting barnacles or stubborn algae taking hold, it’s a pretty clear sign the paint's antifouling muscle is getting weak in that specific area.

The real secret to making your bottom paint last is consistent in-water maintenance. By gently wiping off soft growth before it has a chance to harden, you stop it from digging into the paint's surface and ensure the biocides can keep doing their job effectively.

Knowing When It's Time to Haul Out Again

No paint job lasts forever. Eventually, you’ll see some clear signs that it’s time to start planning your next haul-out. Widespread flaking, significant hard growth that you can't just wipe away, or even a noticeable drop in your boat's speed and fuel efficiency are all tell-tale signs.

Staying ahead of this curve not only keeps your hull protected but makes the prep work for the next paint job a whole lot easier. This proactive approach is becoming more common; the pleasure boat paint market is actually expected to grow by USD 190.9 million by 2028, largely because boaters are looking for more durable, eco-friendly coatings. You can explore more about the pleasure boat paint market trends on Technavio.

Got Questions About Bottom Painting?

Even the most detailed guide can't cover every single question that pops up when you're staring at your boat on the hard. Let's tackle some of the most common ones I hear from boat owners so you can get the job done right.

How Long Does Bottom Paint Last?

This is the million-dollar question, and honestly, the answer is always "it depends."

With a good quality ablative paint in average fouling conditions, and if you’re good about in-water maintenance, you can realistically expect two full seasons of solid protection. Hard paints can technically last longer, but they often lose their antifouling punch after that first year, even if the coating still looks like it's there. So many things—water temp, salinity, and just how much you actually use your boat—will factor in.

Can I Paint Over Old Bottom Paint?

You bet, but with a few big caveats. You can absolutely paint over an old coat as long as it's in good condition and the new paint is compatible with it.

If the existing paint is solid—no major peeling or flaking—just give it a good scuff-sand with 80-grit paper, and you're ready to roll on a new, compatible coat. The cardinal rule here is to never apply a hard paint over a soft ablative paint. It just won't stick and will peel right off. If you're not sure what's already on the hull or you're looking to switch paint types, your safest bet is always to apply a barrier coat primer first.

What’s the Best Temperature for Painting?

For most bottom paints, the sweet spot is somewhere between 50°F and 90°F (10°C and 32°C).

Trying to paint in the blazing sun is a common mistake; it forces the paint to dry way too fast, which messes with adhesion and leaves you with a rough, uneven finish. On the flip side, painting in cold, damp conditions can stretch out your drying times forever and compromise the final cure. Your best source of truth is always the paint can—check the manufacturer’s specific recommendations for temperature and humidity.

Here's a pro tip people often forget: watch the dew point. If your hull's temperature is too close to the dew point, condensation will form on the surface. You can't even see it, but it's an absolute disaster for paint adhesion.

For any job, from quick repairs to a full-boat detail, having the right supplies makes all the difference. At Better Boat, we've developed a complete line of marine-grade products to make maintenance easier. Explore our full collection of cleaners, tools, and accessories at https://www.betterboat.com.