Anchor Bracket for Boat: How to Choose and Install

An anchor bracket for a boat is the piece of hardware that securely holds your anchor, keeping it ready for deployment while protecting your boat from getting banged up and scratched. Think of it as the dedicated holster for your anchor—the unsung hero of your whole ground tackle system.

Why a Solid Anchor Bracket Is Your Boat’s Best Friend

It might not be the flashiest accessory you buy for your boat, but an anchor bracket is one of the most critical. Its job is twofold: wrangling a heavy, awkward piece of metal and protecting your investment. An anchor that isn't stowed properly is a huge liability, especially when the water gets choppy.

Just picture an unsecured anchor swinging around, clanging against your pristine gelcoat with every single wave. That constant impact will inevitably lead to deep scratches, chips, and maybe even structural cracks over time. A proper anchor bracket for your boat completely eliminates that risk by locking the anchor down, safe and sound.

The True Cost of a Subpar Setup

Beyond just cosmetic damage, a flimsy or poorly thought-out mounting solution is a real safety concern. When you need to drop anchor in a hurry—maybe to hold your spot in a crowded cove or deal with an unexpected engine problem—the last thing you want is to be fumbling with a tangled mess. A dedicated bracket keeps your anchor organized and ready for a smooth, snag-free deployment every time.

This vital role is a big reason why the entire boat anchor market is seeing such strong growth. The global market hit a valuation of $3.59 billion in 2024 and is expected to climb to $6.04 billion by 2035. That’s a pretty clear signal that boaters are taking their anchoring setups more seriously than ever.

More Than Just a Holder

Putting a quality anchor bracket on your boat is about more than convenience; it's about peace of mind. It’s a key piece of the puzzle that makes up your boat's ground tackle, working right alongside the rope, chain, and anchor itself to give you security and control. If you want to see how all these parts work together, you can check out our guide to complete anchoring systems for boats.

A well-chosen anchor bracket doesn't just hold an anchor; it holds your boat steady, protects its value, and ensures you're prepared for whatever the water throws your way. It’s a small investment that pays huge dividends in safety and confidence.

How To Choose the Right Anchor Bracket For Your Vessel

Picking the right anchor bracket isn't about grabbing the shiniest piece of hardware off the shelf. It’s a calculated decision. You need to get three things right: the material, the fit for your specific anchor, and the proper size for your boat.

Nail these three, and you'll have an anchoring system that works flawlessly, keeps your anchor secure, and protects your boat when you need it most.

Matching Material to Your Boating Needs

Your first big decision is the material. This choice directly impacts how long the bracket will last, how it will look after a few seasons, and how well it stands up to the abuse of a marine environment.

For most of us, this boils down to two main contenders: 316 stainless steel and heavy-duty galvanized steel.

If you're looking for the top-of-the-line option, stainless steel is it. It offers incredible corrosion resistance, which is a lifesaver in saltwater. Plus, it keeps that polished, clean look for years with just basic upkeep.

Galvanized steel, on the other hand, is the tough, budget-friendly workhorse. It's coated in a thick layer of zinc to fend off rust, making it a solid choice for freshwater boaters or anyone who values pure function over a mirror finish.

Choosing the right material for your anchor bracket is one of the most important steps. Here’s a quick breakdown to help you decide.

Anchor Bracket Material Comparison

| Material | Pros | Cons | Best For |

|---|---|---|---|

| 316 Stainless Steel | Superior corrosion resistance (especially in saltwater), maintains a polished look, high strength, long lifespan. | More expensive upfront, can be heavier than other options. | Saltwater environments, boaters who prioritize appearance and long-term durability. |

| Galvanized Steel | Very durable and strong, cost-effective, good rust resistance from zinc coating. | Can eventually rust if the coating is compromised, less aesthetic appeal than stainless. | Freshwater boating, utility boats, and budget-conscious boaters who need rugged performance. |

| Aluminum | Lightweight, good corrosion resistance, easy to work with. | Not as strong as steel, can be prone to galvanic corrosion if not installed properly. | Smaller boats, pontoon boats, and situations where weight is a primary concern. |

| Marine-Grade Polymer | Corrosion-proof, lightweight, won't scratch the boat's finish. | Lower strength than metal, can become brittle with UV exposure over time. | Small dinghies, kayaks, and applications with very light anchors where strength is not critical. |

Ultimately, your choice should reflect where you boat and what you prioritize. The right material will save you headaches and money down the line.

Pro Tip: If you spend most of your time in saltwater, just spring for the 316 stainless steel. Trust me, you'll thank yourself later when you're not dealing with rust stains bleeding onto your deck. For freshwater folks, galvanized steel offers fantastic performance for the price.

Ensuring a Perfect Fit For Your Anchor

Not all brackets fit all anchors. This is a critical detail. Your bracket needs to be designed specifically for your anchor style—whether you have a Plow, a Danforth, or a Bruce. The goal is a snug, secure fit so your anchor isn't rattling around or shifting while you're underway.

For instance, a bracket made for a classic Danforth anchor has to accommodate its flukes and stock in a way that a bracket for a modern plow anchor just can't. Using the wrong one can lead to the anchor breaking loose in rough water, which is not only noisy but can cause some serious damage to your hull. If you're not sure what you have, our guide on the best boat anchors available can help you sort it out.

Sizing the Bracket for Strength and Safety

Finally, you have to match the bracket's size to your boat's length and your anchor's weight. An undersized bracket is a major weak link in your ground tackle. It has to be beefy enough to handle not just the anchor's dead weight but also all the dynamic forces from your boat pitching and rolling in the waves.

Always check the manufacturer's specs for the bracket’s maximum recommended anchor weight and boat length. Don't guess on this one.

This focus on quality gear is a big deal in the boating world. In fact, the market for boat anchors and hardware in North America is expected to grow at a 3.2% CAGR through 2031. That's no surprise when you consider there are over 12 million registered vessels in the US alone, and every one of them needs a reliable anchoring setup.

Alright, let’s get into what you’ll need to do this job right. A solid anchor bracket installation happens long before you drill the first hole. Getting all your tools and hardware lined up is probably the most important part of the whole process. It’s what separates a secure, watertight, pro-level job from one you’ll regret later.

Trust me, having everything you need within arm's reach will save you from those maddening mid-project runs to the hardware store.

Before you even think about picking up a drill, you need to find the perfect spot. Grab a piece of cardboard and head to your boat's bow. You're looking for the strongest, flattest mounting location you can find—a spot with solid fiberglass reinforcement underneath is ideal. Once you think you've found it, cut out a simple cardboard template of your bracket's base. This little trick lets you see exactly how it will sit, check for clearance, and mark your drill holes without scuffing up your gelcoat.

Your Essential Toolkit

With your location picked out and marked, it's time to gather your gear. You don't need a full-blown workshop, but a few key tools are absolutely non-negotiable for a job you can be proud of.

- Drill and Marine-Grade Bits: A good cordless drill is your best friend here. Make sure you pair it with sharp drill bits specifically designed for fiberglass to avoid chipping or cracking the gelcoat.

- Socket Wrench Set: You'll need this for tightening down the nuts and bolts properly without stripping them.

- Painter's Tape: This is a great pro-tip. Use it to mark your drilling spots. It also helps keep the drill bit from "walking" across that smooth, slick surface.

- Measuring Tape and Pencil: Simple, but essential for accurate measurements and clear marks.

- Safety Gear: Don't skip this. Always wear safety glasses to keep fiberglass dust out of your eyes, and a dust mask is a smart move, too.

The Right Fasteners and Sealant

The hardware you choose is just as critical as the bracket itself. This is one area where you absolutely cannot cut corners. Using the wrong stuff is a recipe for corrosion, leaks, and total failure down the road.

I can't stress this enough: the single biggest mistake I see boaters make is grabbing standard fasteners from the local hardware store. A marine environment is incredibly harsh. Anything less than marine-grade will corrode and fail, putting your entire anchor system at risk.

To secure your anchor bracket for a boat the right way, you must use marine-grade 316 stainless steel bolts, nuts, and washers. This specific alloy is built to resist rust and corrosion, especially in saltwater. We've got a complete lineup of marine fasteners that are guaranteed to handle whatever the water throws at them.

Finally, a top-shelf marine sealant is your last line of defense against water getting into your boat. Applying a generous bead under the bracket and around each bolt hole creates a permanent, waterproof seal. This is what stops water from seeping into your boat's core, which can lead to nasty rot and even structural damage. A product you can count on, like our Marine Sealant & Adhesive, will give you that flexible, watertight bond you need for a lasting, worry-free installation.

Mounting Your Anchor Bracket Like a Pro

Alright, you’ve got your tools and you’ve picked the perfect spot. Now for the fun part: turning that collection of parts into a rock-solid piece of your boat’s anchoring system. This is where all that prep work pays off, and we'll walk through the key steps to make sure your installation is not just strong, but completely watertight.

First up, a simple trick I swear by for a clean job. Before you even think about drilling, lay down a few strips of painter's tape over your marked spots. This does two things: it gives you a much better surface to finalize your marks on, and more importantly, it stops the drill bit from "walking" across that slick gelcoat. Your holes will end up exactly where you want them.

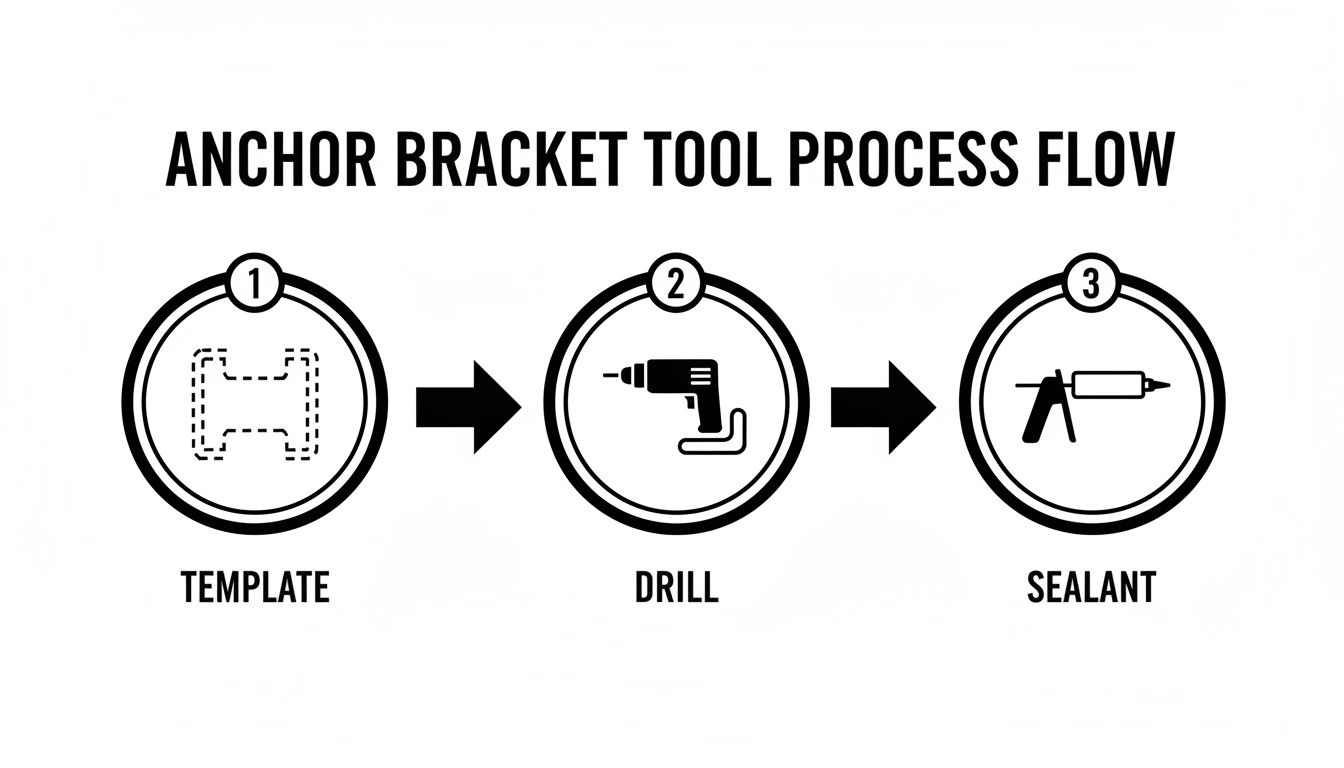

This three-step process is the core of any professional anchor bracket installation.

It really just boils down to careful prep, precise execution, and a thorough seal.

Drilling and Sealing for a Watertight Fit

Time to make some holes. Grab a drill bit that’s just a hair smaller than your bolts to get a really snug fit. Drill slowly and steadily with consistent pressure—don't force it. The idea is to create clean holes without causing any nasty stress cracks in the fiberglass.

With the holes drilled, it’s sealant time. Do not skip this step. This is what keeps water from seeping into your boat's core. Apply a generous bead of high-quality marine sealant around the base of the bracket and put a small ring around each bolt hole on the deck.

A classic mistake is being too stingy with the sealant. Don't be shy. When you tighten the bracket down, you want to see a little bit "squeeze out" around the entire edge. That's your visual confirmation that you’ve created a perfect, waterproof seal.

The type of sealant you use really matters. An anchor bracket for a boat is semi-permanent hardware, so a flexible adhesive sealant is your best bet. If you're wondering which one to grab, our Marine Sealant & Adhesive is a high-strength, flexible choice ideal for this job. For more options, check out our deep dive into 3M 4200 vs 5200 marine sealants to find the right one for your job.

The Importance of a Backing Plate

What happens underneath the deck is just as crucial as what you see on top. A backing plate is absolutely essential. It spreads the immense pulling force from the anchor across a much wider area of the fiberglass. Without one, all that stress is concentrated on the tiny spots around your bolts, which is a recipe for gelcoat cracks or even structural failure down the road.

You can buy a pre-made stainless steel plate or just cut your own from marine-grade plywood or a composite material like StarBoard. The only rule is that it must be larger than the bracket's footprint.

- Position the Plate: Slide the backing plate over the bolts coming through the underside of the deck.

- Add Washers and Nuts: Follow the plate with a washer and then a nut on each bolt.

- Tighten Securely: Snug the nuts down evenly. I like to alternate between them, like tightening lug nuts on a car, to apply uniform pressure.

Getting the Torque Just Right

Finally, let's talk about tightening. The goal is "snug," not "cranked down with all your might." Overtightening is a rookie move that can crush the fiberglass core or create those dreaded spider cracks in your beautiful gelcoat.

Tighten until the bracket is firm and doesn't wiggle, and you see that nice, consistent bead of sealant squeeze-out. That’s your cue to stop. Let the sealant cure for whatever time the manufacturer recommends before you clean up any excess with a bit of acetone. Follow these steps, and you’ll have a pro-grade installation that will hold strong for years of anchoring.

Keeping Your Anchor System in Top Shape

Alright, your new anchor bracket is bolted down, and it looks great. But don't kick back just yet—the job isn't quite done. Keeping that hardware solid and safe for the long haul comes down to good old-fashioned maintenance. A quick inspection every few trips is all it takes to catch a small problem before it becomes a big, expensive one.

Think of it as proactive care. Just a few minutes is enough time to spot things like faint stress cracks in the gelcoat around the bracket's base or the first hint of corrosion on the fasteners. These are your early warning signs. Heed them, and you’ll save yourself a major headache down the road.

Your Quick Inspection Checklist

This isn’t some deep, technical teardown. It's a simple, hands-on check you can do in less than five minutes. Run through this list regularly, and your gear will stay in prime condition.

- Check Fasteners: Get a good grip on the bracket and give it a firm wiggle. You should feel zero movement. If there’s any play at all, you'll need to get underneath and tighten the nuts until it’s rock-solid again.

- Inspect for Corrosion: Get your eyes on the bolts, nuts, and the bracket itself. Saltwater is absolutely relentless, so be on the lookout for any rust or pitting. Pay extra close attention to welds and any little crevices where salt can hide.

- Examine Sealant: Take a look at the bead of marine sealant around the bracket’s base. It needs to be intact and flexible. If you see cracks or gaps, that’s an open invitation for water to seep into your deck core.

Cleaning and Protecting Your Hardware

Keeping your anchor bracket for a boat clean is about more than just looks; it's your first line of defense against corrosion. When salt crystals are left on metal, they attract moisture and kickstart the rusting process—yes, even on stainless steel.

A simple freshwater rinse after every trip, especially in saltwater, is the best habit you can get into. For a more thorough cleaning to get rid of salt spray and stubborn grime, grab a quality marine-grade cleaner. Our Boat Cleaner is perfect for this, as it gently lifts away the gunk without being harsh on your gelcoat or the metal's finish.

To really make it shine and add a layer of protection, follow up with a good Marine Polish. This creates a barrier that helps shed water and prevent future stains, keeping your hardware gleaming all season long.

The most effective maintenance is consistent maintenance. A five-minute rinse and inspection after each use provides more protection than an hour of scrubbing at the end of the season.

Of course, proper upkeep applies to your entire ground tackle setup. To make sure every single component is ready for action, you should check out our complete guide to building a reliable boat anchor system.

Common Questions About Anchor Brackets

Even after a perfect install, you'll probably have a few questions pop up once you start using your anchor bracket day-to-day. We get a lot of the same queries from fellow boaters, so we’ve put together some straight, practical answers to the most common ones.

Getting these little details dialed in is what makes your whole anchoring system work smoothly and, more importantly, safely.

Is a Backing Plate Really Necessary for My Installation?

Yes. One hundred percent. Don't even think about skipping it. A backing plate is the only thing that properly spreads the immense load from your anchor across a wide area of the deck.

Without one, all that focused pressure from the bolts will eventually lead to spider cracks in your gelcoat. In a worst-case scenario, it can cause serious structural damage. Think of it as cheap insurance for your boat's hull—the pulling forces on an anchor are way more powerful than you'd think.

How Do I Mount a Bracket on a Curved Surface?

Mounting an anchor bracket for a boat on a curve takes a little finesse. If it's just a slight curve, you can often get away with using a thick, generous bed of our Marine Sealant & Adhesive. Its gap-filling properties create a solid, level base for the bracket to sit on.

For more pronounced curves, you'll need to get creative and make a custom wedge. A piece of StarBoard is perfect for this. You can shape one side to match the curve of your boat perfectly, while leaving the other side flat and stable for the bracket. This is the pro move to make sure the load is distributed evenly and the bracket doesn't wobble under stress.

What’s the Best Way to Stop My Anchor from Rattling?

That constant clank, clank, clank of a rattling anchor can drive you nuts. The quickest and easiest fix is a heavy-duty rubber bungee cord or a stout strap. Just use it to pull the anchor shank tight against the roller, and the noise is gone. Simple as that.

For a more permanent solution, you could add a chain stopper to your setup. Another trick I've seen work well is adding small, dense rubber pads to the bracket where the anchor makes contact. This cushions it and absorbs the vibrations before they start.

Don't underestimate how much a rattling anchor can ruin a peaceful day on the water. A simple bungee cord is often the most effective and affordable fix for keeping things quiet.

Should I Choose a Fixed or Pivoting Anchor Bracket?

This really boils down to your specific anchor style and how your bow is set up.

- Fixed Bracket: These are simple, incredibly strong, and work great on boats where the anchor can launch cleanly without smacking the bow on its way out.

- Pivoting Bracket: Often part of a full bow roller assembly, a pivoting bracket is the way to go for anchors that need a little help clearing the bow, like many plow-style anchors.

That pivoting action helps guide the anchor up and into its seated position without you having to wrestle with it. It's the best way to prevent those frustrating scuffs and scratches on your hull and just makes the whole process of anchoring feel smoother.

At Better Boat, we know that having the right hardware is just the beginning. Our mission is to provide boaters with everything they need for a safe and enjoyable time on the water, from premium cleaners to top-tier anchoring accessories. Explore our full range of products to keep your vessel in peak condition.