Boat Repair Gel Coat Guide: Perfect Your Repair Today

That glossy finish on your boat isn’t just for show. It’s a critical layer of gel coat, and its job is to protect the fiberglass hull from everything the water and sun can throw at it. Tackling a boat repair gel coat project is all about restoring that protective barrier, stopping minor cracks from turning into major structural headaches. This guide will walk you through exactly what you need to know to get a professional-grade finish.

Understanding Boat Gel Coat and Why It Matters

When you spot a crack, gouge, or a spiderweb of fine lines on your hull, you’re looking at a breach in your boat's primary armor. Gel coat is a pigmented polyester resin that acts as the outermost layer on most fiberglass boats. It’s what gives you that smooth, high-gloss finish while shielding the fiberglass laminate underneath from the harsh marine environment.

Think of it as your first line of defense. Without a solid gel coat, your boat is exposed to two major threats: UV radiation and water intrusion. Sunlight will degrade the fiberglass structure over time, making it brittle. Meanwhile, water can slowly seep into the laminate, leading to osmotic blistering and delamination—expensive problems that can seriously compromise your hull's integrity.

The Importance of Prompt Repairs

Ignoring small chips or cracks is one of the most common mistakes a boat owner can make. Water finds its way into even the smallest fissures. In colder climates, the freeze-thaw cycle will expand those cracks, letting more moisture in. This is why addressing gel coat damage right away isn't just about looks; it's essential preventive maintenance.

The importance of this protective layer is huge. The global gelcoat industry was valued at around USD 1.35 billion in 2023, and the marine sector is its fastest-growing segment. That number really highlights how crucial these materials are for protecting marine investments. You can explore more about the gelcoat market trends and its growth.

Diagnosing Common Gel Coat Issues

Before you start any boat repair gel coat job, you need to know exactly what you’re dealing with. Different problems require slightly different approaches to get a solid, long-lasting fix.

To help you figure out what's going on with your hull, here's a quick rundown of the usual suspects.

| Damage Type | Description | Common Causes | Repair Urgency |

|---|---|---|---|

| Spider Cracks (Crazing) | Fine, interconnected cracks, often in a starburst pattern. | High stress, impacts, or hull flexing. | Medium |

| Chips & Gouges | Deeper damage that often exposes the underlying fiberglass. | Impact with docks, trailers, or debris. | High |

| Oxidation & Fading | A chalky, dull, or faded appearance on the surface. | Prolonged exposure to UV rays from the sun. | Low |

| Blisters (Osmosis) | Bumps or bubbles on the gel coat surface, which may contain a smelly liquid. | Water penetrating the gel coat and hull laminate. | High |

| Stress Cracks | Typically longer, singular cracks, often running parallel to the direction of stress. | Hull flex, structural stress, or hard impacts. | High |

Properly identifying the damage is half the battle. Once you know the cause and type, you can choose the right materials and techniques to make the repair last.

A well-maintained gel coat does more than just make your boat look good—it preserves its structural health and resale value. A small investment in time and materials for a repair now can save you from thousands of dollars in complex fiberglass work later.

Gathering Your Essential Gel Coat Repair Tools

Any pro will tell you that a top-notch boat repair gel coat job is won or lost before you ever pop open a can of resin. The real work starts with having every single tool and material you need laid out and within arm's reach.

Think of it like a surgeon’s tray. Being organized and prepared is what prevents silly mistakes and saves you from a mad dash to the marine supply store mid-project. This prep work is what separates an obvious, amateur patch from a seamless repair that blends right in.

Must-Have Safety and Preparation Gear

Before we even think about mixing, let's get serious about safety. You’re going to be working with some pretty potent chemicals and kicking up fine dust. Protecting yourself isn't optional—it's rule number one.

Your personal protective equipment (PPE) is the most critical tool in your kit. Here's what you can't skip:

- Respirator: A simple dust mask won't do. You need a dual-cartridge respirator rated for organic vapors to handle the styrene in polyester resin.

- Safety Glasses: A non-negotiable for protecting your eyes from chemical splashes or flying debris when you're grinding and sanding.

- Gloves: Go for nitrile gloves. They hold up against acetone and resin much, much better than latex.

- Acetone: This is your best friend for prepping the repair area. It cuts through any wax, oil, or contaminants and is also essential for cleaning your tools when you're done.

- Masking Supplies: Use high-quality painter's tape and some plastic sheeting to shield the surrounding area from accidental scuffs, drips, and overspray.

Get into the habit of putting on your PPE before you even touch the boat. It’s a simple step that protects your health and lets you focus 100% on the quality of your work.

Specialized Tools for a Flawless Application

With your safety gear on, it’s time to grab the tools for the repair itself. While you might be able to get by with the basics, a few specific items will make a massive difference in your final result.

A rotary tool, like a Dremel, fitted with a V-shaped grinding bit is an absolute game-changer. It allows you to carefully bevel the edges of cracks and chips, creating a shallow "V" groove. This little step dramatically increases the surface area for the new gel coat to adhere to, creating a powerful mechanical bond that keeps the repair locked in place for years.

When it comes to application, a good set of flexible plastic spreaders is essential. They let you work the gel coat paste smoothly into the repair, applying just the right amount of pressure to avoid air pockets. You'll also need mixing sticks (tongue depressors are perfect) and a handful of small, disposable mixing cups for whipping up small batches.

Choosing the Right Gel Coat and Materials

Your technique can be perfect, but it won't matter if you're using the wrong materials. The market for these products is huge for a reason. In fact, the pleasure boat gelcoat market was valued at USD 1.2 billion in 2024, and it's only expected to grow as more boaters invest in keeping their vessels looking sharp. You can dive deeper into these marine coating market trends if you're curious.

Here’s a quick rundown of the key players:

| Material | What It's For | Pro Tip |

|---|---|---|

| Gel Coat Paste | The heart of your repair. It's a thick, putty-like material designed to fill gouges and deep scratches without sagging or running. | Don't cheap out. Always buy a high-quality marine-grade product. The cheaper stuff often cures poorly and yellows quickly under UV light. |

| Color Pigments | Used for tinting white or neutral gel coat to get that perfect match for your boat's hull, which has likely faded a bit over time. | Add pigments a tiny drop at a time. It’s way easier to add more color than it is to take it away. Always mix a small test batch first. |

| MEKP Catalyst | This is the hardener. It kicks off the chemical reaction that cures the gel coat. Getting the ratio right is absolutely critical. | Temperature and humidity play a big role. On cold days, you might need a bit more catalyst; on hot, humid days, you'll need a bit less. |

| Finishing Wax Additive | A liquid wax you mix into your final coat. As the gel coat cures, the wax rises to the surface, sealing it from the air so it can harden completely tack-free. | Only add this wax to your very last layer. If you're building up a deep repair, leave the wax out of the initial coats to ensure they bond. |

Preparing the Surface for a Lasting Repair

If you ask any seasoned marine tech the secret to a perfect, invisible gel coat repair, they'll tell you it has almost nothing to do with the final application. The real magic happens long before you even think about mixing resin. Meticulous surface prep is the absolute foundation of any successful boat repair gel coat job—I’d say it’s easily 90% of the entire process.

Cutting corners here is a guaranteed ticket to doing the same job twice. A poorly prepped surface means you’ll be looking at peeling, cracking, or discoloration within a single season. Getting this part right from the start is the only way to ensure the new gel coat forms a permanent, powerful bond with the existing hull.

Creating a Pristine Surface for Adhesion

The number one enemy of a good repair is contamination. Your boat's hull is coated in a thin film of wax, old polish, oil, and general grime. If you try to patch over this layer, the new gel coat simply won't stick. It needs a perfectly clean slate.

This is where acetone becomes your best friend. Grab a couple of clean rags. Soak one in acetone and generously wipe down the damaged area and a few inches surrounding it. Immediately follow with the second, dry rag to wipe it clean.

Using a separate dry rag is key—otherwise, you're just smearing the contaminants around. I always repeat this process two or three times just to be absolutely certain the surface is squeaky clean.

Beveling Edges for a Stronger Mechanical Bond

Once the area is spotless, it's time to deal with the shape of the damage itself. A simple chip or a tight hairline crack has sharp, vertical edges that offer almost no surface area for the new gel coat to grab onto. To solve this, you need to create a bevel.

Using a Dremel with a V-shaped grinding bit or even a simple countersink bit, carefully grind the edges of the crack or chip into a shallow "V" shape. You're aiming for a gentle slope from the outer edge of the damage down to its deepest point.

This quick step accomplishes two critical things:

- Increases Surface Area: That sloped edge dramatically expands the amount of surface the new gel coat can physically bond to.

- Creates a Mechanical Lock: The "V" groove acts like a keyway, physically locking the repair patch in place so it can't pop out under stress or when the hull flexes.

Think of it like a dovetail joint in woodworking; the shape itself provides incredible strength. If you’ve ground down deep enough to expose the fiberglass mat underneath, you'll need to approach it a bit differently. For those more complex structural fixes, our guide on epoxy and fiberglass repair offers a much deeper dive.

Masking Off the Repair Zone

With the damage cleaned and beveled, your final prep step is to protect the surrounding area. It's shockingly easy to slip with a sander or have a drop of resin go rogue, and the last thing you want is to create another repair for yourself.

Use high-quality painter's tape to create a crisp, clean border around the entire repair zone. If it's a larger job, I'll use masking paper or plastic sheeting to cover more real estate. This not only protects the good gel coat but also gives you a clear boundary to work within.

A common mistake is taping too close to the repair. Leave about a quarter-inch of space between the tape and the beveled edge. This allows you to slightly overfill the repair and then sand it down perfectly flush with the surrounding surface.

Once your surface is clean, beveled, and masked off, you have officially built the perfect foundation. This careful work is what ensures your boat repair gel coat doesn't just look good when you're done, but actually holds up to sun, salt, and spray for years to come. Now you’re ready to start mixing and applying your gel coat with confidence.

Mixing and Applying Gel Coat Like a Pro

Alright, this is where all that tedious prep work starts to pay off. You’re about to bring that repair to life, transforming a gouge or crack into a seamless, professional-looking surface. It's part science, part art, but with the right technique, you can absolutely nail it.

One of the first hurdles is color matching, especially on a hull that’s seen a few seasons under the sun. A brilliant white patch on an older, slightly yellowed hull will stick out like a sore thumb. The trick is to use tinting pigments. Add them drop by drop to your white gel coat until you get that perfect off-white hue. Always mix a tiny test batch first and let it kick off so you can see the final cured color before you commit to the whole repair.

Mastering the Catalyst Mix

The magic that turns that thick gel coat paste into a rock-hard solid is the MEKP (methyl ethyl ketone peroxide) catalyst. Getting this ratio right is probably the single most critical step for a successful cure. Too little, and you'll be left with a soft, tacky mess that never hardens. Too much, and it'll cure too fast, becoming brittle and likely to crack down the road.

The standard rule of thumb is a 1% to 2% catalyst-to-gel-coat ratio by volume.

As a quick guide:

- 1% Ratio: Roughly 10 drops of MEKP for every ounce of gel coat.

- 2% Ratio: Roughly 20 drops of MEKP for every ounce of gel coat.

Temperature is the deciding factor here. On a hot day (over 80°F), you'll want to lean toward a 1% mix to buy yourself more working time before it starts to set up. If it's cooler (60-70°F), a 2% mix is better to ensure it cures properly. Never even think about attempting a gel coat repair below 60°F—the chemical reaction just won't happen correctly.

For a more precise mix, here’s a handy chart that breaks down the ratios based on ambient temperature. This can be a real lifesaver and takes a lot of the guesswork out of the process.

MEKP Catalyst Mixing Ratios by Temperature

| Temperature (°F / °C) | Catalyst Percentage (by volume) | Approx. Gel Time (Minutes) | Notes |

|---|---|---|---|

| 60°F / 16°C | 2.0% | 20-25 | Minimum recommended temperature. Curing will be slow. |

| 70°F / 21°C | 1.5% | 15-20 | A good average temperature for controlled results. |

| 80°F / 27°C | 1.25% | 10-15 | Ideal working conditions. Gel time is manageable. |

| 90°F+ / 32°C+ | 1.0% | <10 | Work quickly in small batches. Gel coat can "kick" very fast in direct sun. Avoid if possible. |

Getting this mix right ensures your patch will have the strength and durability it needs to last for years.

Applying the Gel Coat for a Perfect Fill

Once your color is dialed in and the catalyst is mixed thoroughly, it’s go-time. Grab a flexible plastic spreader and start working the paste into the beveled repair area. Use firm, even pressure to push out any trapped air bubbles, which can create weak spots or voids in the final patch.

You need to slightly overfill the repair area. Gel coat shrinks as it cures—usually around 5-7%—so building the patch up just proud of the surrounding surface is essential. This gives you enough material to sand down for that perfectly flush, invisible blend.

For deeper gouges, don't try to fill it all in one go. The best approach is to work in thin layers, letting each one cure before adding the next. This prevents the heat buildup that can happen with a large mass of curing resin and ensures the entire repair hardens evenly.

For really deep structural damage, knowing when to use gel coat versus a stronger filler is key; our guide on using epoxy resin for boat repair can help you make the right call.

Ensuring a Tack-Free Cure

Standard laminating gel coat is designed to stay tacky on the surface when exposed to air. This is perfect when you're building up layers because it creates a strong chemical bond between them. But for your final coat, you need a hard, sandable surface.

You've got two main ways to achieve this:

- Wax Additive: This is the most common method. You simply mix a surfacing wax solution into your final batch of gel coat. As the gel coat cures, the wax rises to the surface and forms a protective barrier against the air, allowing it to harden completely.

- PVA Curing Agent: Alternatively, after applying your final coat of unwaxed gel coat, you can spray or brush on a layer of PVA (polyvinyl alcohol). It’s a water-soluble plastic film that creates an air barrier. Once the patch is hard, the PVA washes right off with water.

Don't skip this step. If you leave that final coat exposed to the air, you’ll have a sticky disaster on your hands that will clog your sandpaper instantly.

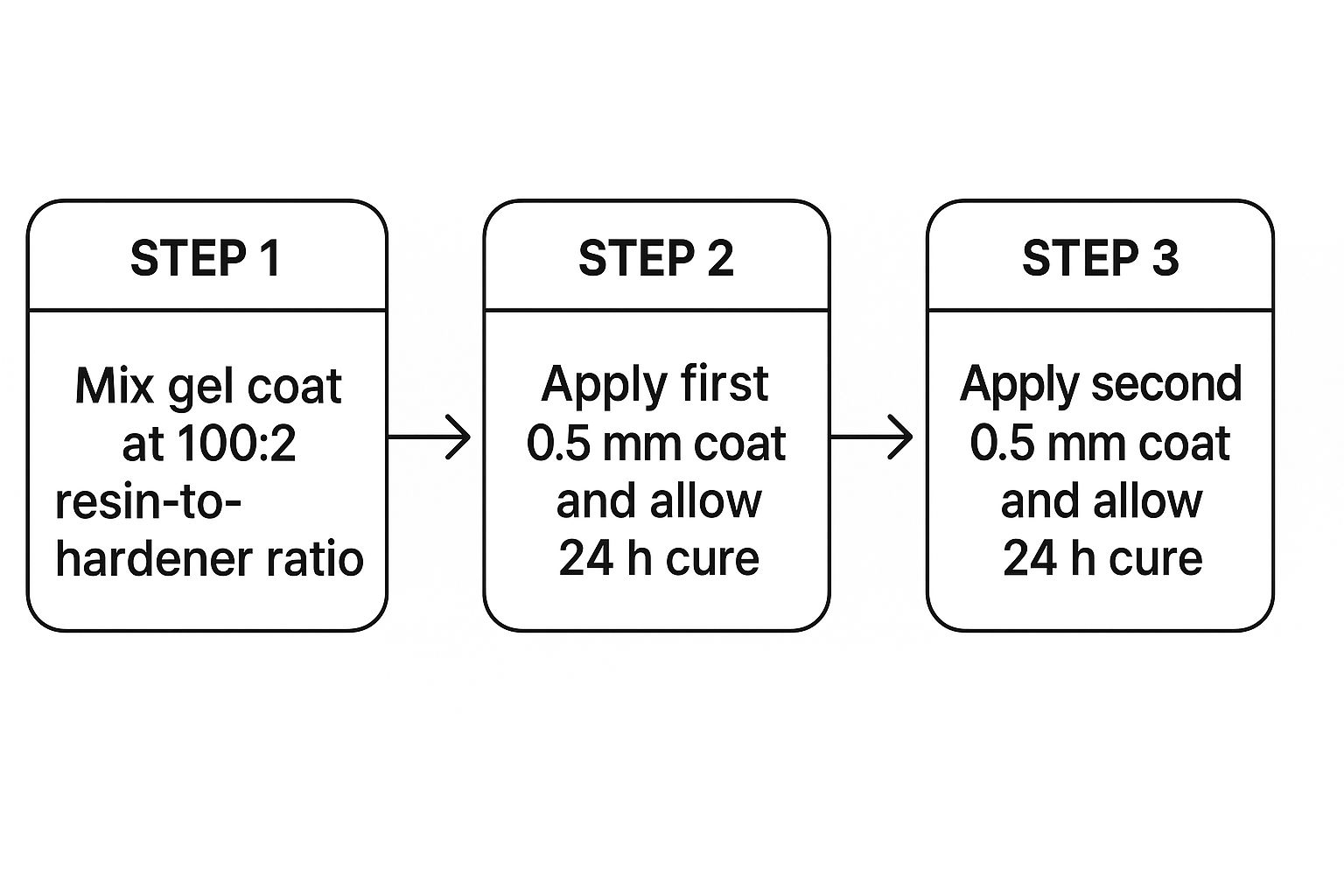

This visual shows why that systematic, layer-by-layer approach is so important. Ensuring each layer is properly cured before adding the next is critical for the final strength of any deep boat repair gel coat project.

Remember, patience is your greatest tool during the curing process. Rushing to sand before the gel coat is fully hardened will ruin your hard work. Depending on the temperature and catalyst ratio, allow at least several hours, or even overnight, for a complete cure.

Finishing and Polishing for an Invisible Blend

You’ve laid down your gel coat patch and let it cure, but now you're looking at a dull, slightly raised spot. Don't worry, this is exactly where you want to be. The next steps are where the real magic happens, transforming that obvious repair into a seamless part of your hull.

This is the part of the job that separates a passable fix from a professional-grade boat repair gel coat project. It all comes down to a careful, systematic process of sanding, compounding, and polishing. If you rush this, you'll be left with scratches and swirls that are a dead giveaway of a repair. Take your time here—patience is your best tool.

The Art of Wet Sanding for a Flawless Surface

First things first: never, ever dry sand gel coat. It’s a surefire way to generate too much heat, which can damage the finish, and it will clog your sandpaper in seconds. Wet sanding is the only way to go. The water acts as a lubricant, whisking away the sanded material and keeping your sandpaper clean.

And please, use a firm sanding block. I've seen too many people try to sand by hand, and it always ends the same way: with a wavy, uneven finish. Your fingertips can't apply consistent pressure. A block is the only way to level the repair perfectly flat with the surrounding gel coat.

Here’s the grit progression I’ve used on countless jobs. It works every time.

- Start with 320-Grit: This is your leveling stage. The goal is to carefully knock down the high spots of the patch until it's perfectly flush with the original hull. The best tool you have for this is your fingertips—run them over the edge. You shouldn't be able to feel a transition.

- Move to 600-Grit: Once it’s flush, switch to 600-grit. This step is all about removing the deeper scratches left behind by the 320-grit paper.

- Progress to 800-Grit: Now you're just refining the surface, erasing the 600-grit scratches and prepping the area for the final polish.

- Finish with 1200-Grit (or higher): This is the last stop for sanding. It will leave the surface feeling silky smooth, with just a light haze.

Pro Tip: Keep a spray bottle of water handy and mist the area constantly. You'll also want a bucket of water to dip your sandpaper in frequently. This keeps the paper from clogging up and makes the whole process go much smoother.

Restoring Gloss with Compound and Polish

Now that the sanding is done, you've got a perfectly flat but very dull surface. It’s time to bring back that deep, boat-show shine. This is a two-step process that really needs a machine buffer to get right. A variable-speed rotary or a good dual-action (DA) polisher will make all the difference.

Think of this part as liquid sanding. You'll start with a more abrasive compound to remove the fine sanding scratches, then move to a finer polish to bring out that mirror finish.

Step 1: Using a Rubbing Compound

Grab a quality marine rubbing compound and a wool or medium-cut foam compounding pad. Dab a few small spots of compound on the pad and directly on the repair area.

Work in a small section, about two feet by two feet. Set your buffer to a low or medium speed—somewhere around 1200-1500 RPM for a rotary works great. Move the buffer slowly and steadily, applying light, even pressure. You'll see the haze from the sandpaper disappear and a satisfying gloss start to emerge.

Step 2: Achieving a Mirror Shine with Polish

Wipe off all the compound residue with a clean microfiber towel. Now, switch to a soft foam finishing pad and grab your marine polish.

Apply the polish just like you did the compound. Use the same technique but back off on the pressure a little. The polish will buff out any tiny swirls left by the compound, dialing up the gloss to that brilliant, wet look. This is the final touch that makes your boat repair gel coat work truly vanish.

To protect all your hard work, finish it off with a high-quality marine wax. This adds that final bit of pop and seals the finish. If you're curious about the best options, check out our guide on choosing the best marine wax and polish for your boat. Your repair is now fully protected and completely invisible.

Common Boat Gel Coat Repair Questions

Even the most detailed instructions can leave you scratching your head when you're in the middle of a hands-on project. When it comes to a boat repair gel coat job, a few common problems seem to pop up for just about everyone. Let's walk through some of those frequent questions with clear, no-nonsense answers.

One of the first things people ask is whether they can just slap new gel coat over the old stuff. You should never apply new gel coat over paint—it absolutely has to be stripped off first. You can, however, apply it over an old, properly prepared gel coat surface. The secret is in the prep work: the old surface needs to be de-waxed, wiped down with acetone, and then sanded aggressively with something like 80-grit paper. This roughs it up enough to give the new coat something to really bite into.

Why Is My Gel Coat Repair Not Hardening?

It's a classic boat repair headache. You followed the steps, but you’re left with a sticky, tacky mess instead of a hard finish. Nine times out of ten, it’s one of these simple culprits.

- Wrong Catalyst Ratio: This is the big one. Too little MEKP catalyst, or just not mixing it in thoroughly enough, is the number one reason for a soft cure.

- Chilly Temperatures: Gel coat is fussy about the cold. It really struggles to cure properly below 60°F (15°C). The chemical reaction just grinds to a halt.

- Air Exposure: If you used a laminating (non-waxed) gel coat for your final layer without covering it, the air will stop it from hardening. You have to seal it off with a PVA film or even just a piece of plastic wrap to get a hard cure.

A proper, rock-hard cure is non-negotiable for a repair that's going to last. Always double-check your mix ratio, work in a warm spot, and make sure that final coat is sealed off from the air. That's how you get a finish you can actually sand.

How to Get a Perfect Color Match for a Faded Hull

This is where the real skill comes in. Trying to match the color of a weathered, sun-bleached hull is tough. A patch of brilliant, brand-new white on a ten-year-old boat will stick out like a sore thumb.

Before you even think about mixing, start by compounding and polishing a small area right next to your repair. This will cut through the oxidation and reveal the hull's true, original color, giving you a much better target to aim for.

From there, grab a gel coat color matching kit. These come with a variety of pigments you can add. Working with a small amount of white gel coat, add your tints literally one drop at a time. It's often just a hint of brown or yellow that nails that perfectly aged, off-white look. Mix a tiny test batch, add a drop of catalyst, and spread it on some cardboard to cure. Patience is your best friend here—keep adjusting and testing until it's a dead-on match before you ever touch the hull.

For a broader range of insights and solutions, you might also find value in these Effective Boat Gelcoat Repair Tips.

At Better Boat, we provide all the premium supplies you need to tackle your gel coat repairs with confidence. From professional-grade materials to the essential tools for a flawless finish, find everything at https://www.betterboat.com.