How to Winterize an Outboard Motor: Quick Guide

To do the job right, winterizing an outboard motor means stabilizing the fuel, flushing the cooling system, fogging the engine internals, changing the lower unit gear oil, and protecting everything from corrosion.

If you skip these steps, you're setting yourself up for a world of hurt from freezing water, bad fuel, and rust—all of which lead to a hefty repair bill come springtime.

Why Winterizing Your Outboard Is So Critical

As the boating season winds down, it’s tempting to just throw a cover on the boat and call it a day. I get it. But walking away from your outboard without winterizing it isn't a small gamble—it's a direct route to expensive, and completely avoidable, repairs.

This is about more than just getting ready for the cold; it’s about protecting your engine and making sure your investment is ready to go for years to come.

Think of it as cheap insurance for your engine’s health. Over the offseason, your outboard is up against a nasty trio of threats: freezing water, fuel gone bad, and corrosion. Each one is a silent killer for a different part of your motor.

The Dangers Of Neglect

For anyone in a cold climate, the most immediate danger is water left trapped in the cooling passages. When water freezes, it expands by about 9%, and that expansion creates an incredible amount of pressure. It’s more than enough to crack an engine block or gearcase, turning a simple oversight into a repair job that can easily run into the thousands.

But even if you're not in a deep freeze, old fuel is a major problem. In just a few months, gasoline breaks down, leaving behind gummy deposits that will clog up carburetors, injectors, and fuel lines. That's what leads to those frustrating no-start days or a motor that sputters and stalls right when you've finally gotten back on the water.

Key Takeaway: Winterizing isn't just a suggestion for boaters in cold climates. It’s a vital maintenance routine that guards against fuel system clogs, internal rust, and catastrophic freeze damage. It's what ensures your outboard will be reliable next season.

An Investment In Your Next Season

Properly prepping your outboard is just part of responsible boat ownership. A surprising number of engine failures in the spring can be traced directly back to how the boat was stored over the winter.

Leading manufacturers like Mercury Marine constantly warn that failing to winterize can cause massive engine damage from freezing temperatures alone. It’s a good idea to see what they have to say about winterization to get the perspective straight from the source.

The logic behind winterizing your motor lines up with general preventive maintenance best practices for any piece of machinery. Taking care of your outboard is just one piece of the puzzle, and we cover the whole picture in our complete guide to winterizing your entire boat.

Protecting Your Fuel System for Winter Storage

Your outboard's fuel system is the first place trouble starts brewing during long-term storage. Trust me, leaving untreated fuel in the tank for months is a surefire recipe for a miserable spring startup. That old gas breaks down, leaving behind a gummy varnish that loves to clog up injectors and carburetor jets.

Getting the fuel situation sorted out is probably the most critical part of learning how to winterize an outboard motor correctly.

First things first, you need to decide whether to store your fuel tank full or empty. The right answer really depends on your setup. If you're working with portable tanks—usually the six-gallon red plastic ones—it's often best to just run the motor until the tank is bone dry. This completely removes the chance of bad fuel causing headaches next season.

For built-in tanks, however, you'll want to do the exact opposite. An empty or even partially full tank is just asking for condensation to form as the temperatures swing up and down. Water in your fuel is a huge problem, leading to corrosion and rough engine performance.

Treating and Circulating Your Fuel

For those built-in tanks, go ahead and fill them up to about 95% capacity. This leaves a little bit of room for the fuel to expand on warmer days but dramatically cuts down on the air space where condensation can build up.

Once it's filled, it's time to add a quality marine fuel stabilizer. Be sure to follow the directions on the bottle to add the right amount for the volume of fuel you're treating.

But don't stop there. Just dumping the stabilizer into the tank won't do the trick. You need to get that treated fuel circulated through the entire system—the fuel lines, filters, and all the way to the carburetors or injectors.

Crucial Tip: After adding stabilizer, you absolutely have to run the engine for at least 10-15 minutes. This is the only way to ensure the protective blend gets into every nook and cranny, guarding against fuel breakdown and corrosion all winter long.

This is a fundamental part of good engine care. You can find more practical advice like this in our comprehensive guide to outboard motor maintenance.

Don't Forget the Fuel Filter

While you've got the engine running to circulate that stabilized fuel, it's the perfect opportunity to deal with your fuel-water separating filter. Think of this filter as the last line of defense protecting your engine's sensitive guts from water and junk. You'd be amazed at how much water it can collect over a single season.

Swapping this filter out now is a smart, proactive move. Here's why it's so important:

- Prevent Freezing: Any water trapped inside the filter can freeze solid, potentially cracking the filter housing. That could lead to a dangerous fuel leak when you fire up the engine in the spring.

- Start Fresh: It guarantees you begin next season with a clean, efficient filter, which helps prevent fuel flow problems right from the get-go.

- Easy Diagnosis: When you take the old filter off, inspect what comes out. It can give you an early heads-up if you have a bigger water contamination issue in your fuel tank.

Replacing the filter is usually pretty simple. Just make sure you have a drip pan handy to catch any spills, and dispose of the old filter and its contents responsibly. Taking care of this final step completes your fuel system prep and sets you up for a smooth, trouble-free start to the next boating season.

Flushing and Fogging the Engine: Your Outboard’s Winter Coat

With your fuel system stabilized for its long winter nap, it's time to turn our attention to the engine itself. This part of the process involves two of the most critical steps: flushing out all the gunk from a season on the water and then fogging the internals to prevent rust. Think of it as giving your engine a thorough cleaning before tucking it in with a protective blanket.

This is the bread and butter of fall maintenance for boat owners. In North America, which accounts for over 41% of the entire global marine outboard engine market, this annual ritual is what keeps service centers busy and DIYers stocking up on supplies. Getting this part right is a big deal.

First, Flush Out Salt and Grime

Let's start by flushing the cooling system. Every time you run your boat, the engine pulls in water—and everything in it. Over a season, that means salt, sand, silt, and all sorts of mineral deposits build up inside the cooling passages. If you leave that stuff in there all winter, you're asking for corrosion and blockages that can lead to a nasty overheating surprise next spring.

Flushing is an absolute must, especially if you spend any time in saltwater. You’ve got two main ways to get it done:

- "Ear Muffs": These are your classic flushing tool. Our durable outboard motor flusher fits snugly over the water intakes on the lower unit, letting you hook up a garden hose and run the engine safely out of the water.

- Flushing Port: Most newer outboards come with a handy built-in port for a hose connection. The big advantage here is you can flush the engine without even having to start it. Just be sure to check your owner’s manual, as some engines have very specific instructions for using this feature.

Whichever method your engine calls for, let fresh water run through it for a solid five to ten minutes. You want to be sure every last bit of grime and salt is washed out. For an even deeper clean, I’m a big fan of using a dedicated flushing solution to really dissolve stubborn salt buildup. For a step-by-step on how to do that, check out our guide on using a Salt-Away engine flush.

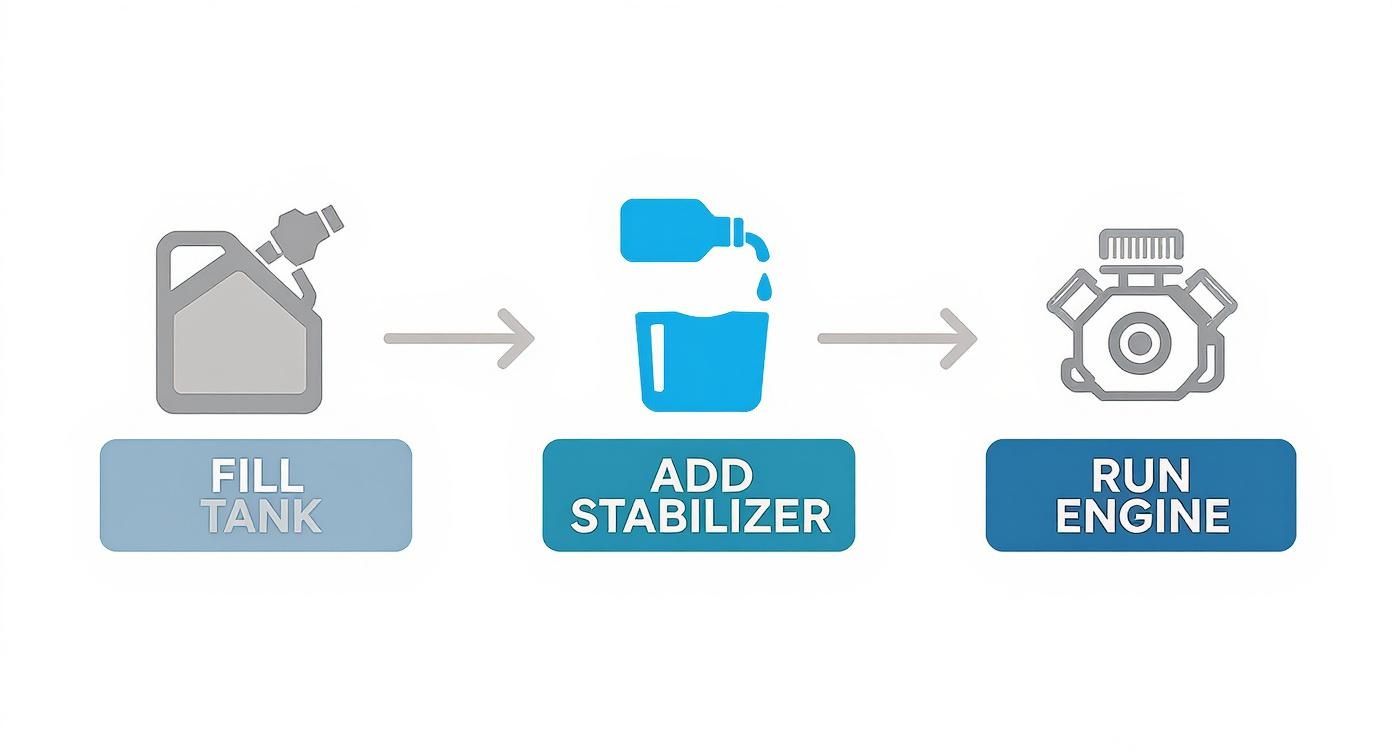

Before you even start flushing, you should have already taken care of the fuel stabilizer. This graphic is a good reminder of that simple but crucial sequence.

It’s always the same order: fill the tank, add your stabilizer, and then run the engine long enough to get that treated fuel circulated all the way through the system.

Next, Apply a Protective Layer of Fogging Oil

Once the engine is flushed clean, it's time to fog it. This process coats all the internal metal surfaces—pistons, cylinder walls, crankshaft, you name it—with a thin film of specialized fogging oil. This oily shield is what stops moisture in the air from creating rust on those vital components while the boat sits idle.

Expert Tip: I've seen it happen: someone skips the fogging step to save a few minutes and a few bucks. Come springtime, they’re looking at a seized engine from internal corrosion, which is a seriously expensive fix. Don't be that person.

How you fog your engine depends on whether it’s carbureted or fuel-injected.

- For Carbureted Engines: With the engine running at a fast idle (while on the ear muffs), spray the fogging oil right into the air intakes of the carburetors. Keep spraying until you see thick white smoke puffing from the exhaust and the engine starts to bog down. As it sputters, kill the ignition. That’s how you know the oil has been pulled all the way through.

- For Fuel-Injected Engines (EFI/DFI): Hold on—don't just spray into the intake on these. Modern fuel-injected engines can be sensitive, so your owner’s manual is your best friend here. Most manufacturers will tell you to pull the spark plugs and spray a quick, one-second shot of fogging oil directly into each cylinder. Once you’ve done that, give the flywheel a few manual turns to make sure the oil spreads evenly across the cylinder walls.

By flushing out the bad and coating with the good, you’re locking in your engine's health for the entire offseason. Come spring, you’ll be rewarded with a motor that fires right up, ready for another season of fun.

Changing Lower Unit Gear Lube and Protecting Your Prop

With the fuel system and engine internals prepped for their long winter nap, it's time to turn our attention to the lower unit, also known as the gearcase. This is the submerged powerhouse of your outboard, and inside that torpedo-shaped housing, a precise set of gears translates the engine's power into propeller spin.

The only thing keeping those expensive gears from grinding themselves into metal shavings is a surprisingly small amount of gear lube. Skipping this step is, without a doubt, one of the most costly mistakes a boat owner can make.

The gear lube does more than just lubricate; it also helps cool the gears and fight off corrosion. But its most important job during winterization is to act as a crystal ball, telling you if there's a serious problem brewing.

Draining and Inspecting the Old Lube

First, get a decent-sized drain pan and slide it under the lower unit. You'll spot two flat-head screws on the gearcase: a lower drain screw and an upper vent screw. Always start by loosening and removing the bottom screw first. A little bit of oil might dribble out, but the real show starts when you remove the top vent screw, which allows air in and lets the lube drain freely.

Now for the important part: pay close attention to what comes out. This is your one chance to diagnose the health of your gearcase seals before it's too late.

- Healthy Lube: Good gear lube will have a consistent color, often amber, blue, or even green, and should be translucent. It might be dark from use, and that's perfectly normal.

- Contaminated Lube: If you see a milky, creamy, or coffee-colored mess draining out, you have a problem. That's the unmistakable sign of water intrusion past a failed seal.

A milky appearance is a massive red flag. It means water is getting into your gearcase, and if left over the winter, that water will freeze, expand, and crack the housing wide open. That's a repair that can run into the thousands.

Critical Warning: Never, ever ignore milky gear lube. Water in the lower unit is a sign of failed seals. When that water freezes, it expands with enough force to crack the entire gearcase, resulting in a catastrophic and wallet-crushing failure.

Refilling with Fresh Gear Lube

Once every last drop of the old stuff is out, it's time to refill. The trick is to always fill from the bottom up. This method pushes all the air out as you fill, preventing air pockets that can starve your gears of lubrication and lead to a meltdown.

Get your bottle or pump of fresh gear lube and thread the nozzle into the bottom drain hole. Start pumping until you see fresh, clean fluid begin to stream out of the top vent hole.

Here's the key move: while keeping pressure on the pump to prevent lube from running back out, quickly re-install the top vent screw first. Once it's snug, you can remove the pump from the bottom hole and immediately replace the bottom drain screw. Tighten both screws securely, but don't go crazy and strip the threads.

Inspecting and Greasing the Propeller

While you're working on the lower unit, it’s the perfect time to give your propeller some love. Pop off the cotter pin, unscrew the castle nut, and slide the prop right off the shaft.

Give the prop a good, hard look. Check for any dings, bent blades, or cracks that could throw it off balance, causing vibrations that can wreck your new seals over time. Even small damage can have a big impact. If you're thinking about a change, it helps to know the pros and cons of stainless steel and aluminum propellers to pick what's right for your boat.

To finish the job, slather a generous amount of quality marine-grade grease on the propeller shaft splines. This simple step prevents the prop from seizing onto the shaft, making it a breeze to remove next spring. You can then reinstall the prop or store it separately in a safe place for the winter.

Final Steps for Total Corrosion Protection and Storage

With the guts of your outboard now prepped for the long winter nap, it's time to turn our attention to the outside. This is where we lock in all that hard work, shielding your motor from the elements and making sure every moving part is ready to go come springtime.

Skipping these final steps is a recipe for headaches. You can end up with seized steering, corroded electricals, and moisture damage—all things that can turn your first warm-weather launch day into a frustrating repair session.

Lubricating Key Pivot and Steering Points

First thing's first: grab your grease gun. You'll want it loaded with a quality marine-grade grease. The goal here is simple but crucial—force fresh grease into all the moving parts to prevent them from seizing up from months of inactivity and damp air.

Here are the non-negotiable spots to hit:

- Steering Tube: This is a classic trouble spot. Pump new grease into the zerk fittings until you see the old, nasty grease getting pushed out. That’s how you know you’re done.

- Tilt and Trim Mechanism: Hunt down all the grease fittings on the tilt tube and its pivot points. A fresh shot of grease here keeps everything moving smoothly and protects the hydraulic rams from pitting.

- Shift and Throttle Linkages: You don't need to go crazy here, but a light coat of grease on these linkages ensures they won't bind up over the winter.

Trust me, this little bit of effort with a grease gun is what separates a smooth spring launch from a day spent wrestling with a frozen steering system.

Applying an Anti-Corrosion Shield

Now, let's protect the heart of the beast—the powerhead. Pop off that big engine cowling and give the entire engine a light misting with a corrosion inhibitor spray. This isn't just any spray; it's designed to displace moisture and leave a thin, waxy film that acts as a barrier against rust. This is especially important if you're storing the boat in a damp garage or humid climate.

You’ll want to coat the metal parts, electrical connections, and bolt heads. Just be careful to avoid spraying it directly onto any belts or the air intake. It's one of the best things you can do to prevent that slow, silent damage moisture loves to inflict.

Pro Tip: While you've got the cowling off, take a second to wipe down the rubber gasket with a clean cloth. This helps it create a tight seal when you put it back on, which is your engine’s first line of defense against moisture getting inside.

Battery Care and Final Storage Position

Don't forget about your battery. Start by disconnecting the negative terminal, then the positive. If you see any of that crusty white or blue corrosion on the terminals, clean it off with a wire brush before giving them a quick wipe-down.

For the best possible lifespan, pull the battery out of the boat entirely. Store it somewhere cool and dry—and never directly on a concrete floor. Hooking it up to a battery tender or trickle charger will keep it healthy and ready for action in the spring.

Finally, the way you leave your motor is critical. Always store your outboard in the fully down (vertical) position. This is non-negotiable. It allows every single drop of water to drain out of the cooling system and gearcase, completely eliminating the risk of ice expanding and cracking something expensive.

With your motor properly positioned, the last step is to throw on a quality boat cover. You need one that's breathable. A good cover keeps snow and rain out but still allows air to circulate, which is what prevents mold and mildew from turning your boat into a science experiment. Durable boat covers are designed to give you exactly that mix of protection and breathability, keeping your entire investment safe all winter long.

Common Questions About Winterizing Outboards

Even with a perfect step-by-step guide, you’re bound to have some questions pop up, especially if it's your first time tackling this job. That's perfectly normal. Knowing how to winterize an outboard motor is less about just following a checklist and more about understanding why each step matters.

Let's clear the air on some of the most common points of confusion I hear from other boat owners. Getting these right will give you total confidence that you’re protecting your engine the right way.

Do I Really Need to Winterize in a Milder Climate?

Absolutely. I get this one a lot from folks down south. While avoiding freeze damage is the number one reason for winterizing up north, the process is just as critical no matter where you live. Think of it as "storage prep" more than just "winterizing."

Humidity is your engine's silent enemy. That fogging oil we talked about? It’s there to coat every internal part to stop rust and corrosion from forming due to condensation inside the engine. And fuel? Gasoline starts to go bad in just a few short months, leaving behind gummy deposits that will clog up your entire fuel system. A stabilizer isn't optional; it's essential everywhere.

Key Insight: Winterizing isn't just about the cold. It’s a complete storage prep process that fights fuel degradation, internal corrosion from humidity, and seized parts, ensuring a reliable start in the spring, even if you never see a snowflake.

What Is the Biggest Mistake People Make?

Hands down, one of the most catastrophic and expensive mistakes is finding milky gear lube in the lower unit and just ignoring it. I've seen it happen more times than I can count. That milky, coffee-colored oil means water has gotten past a seal.

If that trapped water freezes, it expands with incredible force and will crack your gearcase wide open. That turns a simple, cheap seal replacement into a repair bill that can easily run into the thousands. Don't ignore it.

Another huge one is messing up the fuel treatment. People either forget the stabilizer completely or they pour it in the tank and call it a day. You have to run the engine long enough for that treated fuel to circulate through every inch of the system—the fuel lines, the filters, and the carburetor or injectors. If you don't, you’re guaranteeing yourself a frustrating, no-start headache come springtime.

Should I Store My Fuel Tank Full or Empty?

This is a classic debate at the marina, and the correct answer really hinges on what kind of fuel tank you have.

- Permanently Installed Tanks: For built-in tanks, the best practice is to fill them to about 95% capacity. Then, add a quality marine fuel stabilizer. A nearly full tank leaves very little room for air, which is what causes condensation to form and contaminate your fuel with water over the winter. Less air, less water. Simple as that.

- Portable Tanks: With smaller, removable tanks, you’ve got a couple of options. Many boaters, myself included, prefer to run them completely dry. This completely eliminates any chance of old fuel gumming things up. However, if you do store a portable tank with fuel, follow the same rule: fill it to 95% with stabilized fuel and store it in a safe, well-ventilated spot away from any potential sparks or flames.

At Better Boat, we know that protecting your investment through the off-season is just as important as enjoying it on the water. From our durable, breathable boat covers to our full range of maintenance supplies, we provide everything you need to do the job right. Explore our complete collection at https://www.betterboat.com and get your vessel ready for a worry-free winter.