Diagnosing and Fixing a Spun Hub on Propeller

You're out on the water, you throttle up to get on plane, and something feels...off. The engine screams, the RPMs shoot sky-high, but your boat just wallows in the water, barely making headway. What you're likely dealing with is a classic spun hub on propeller.

It’s a frustrating and surprisingly common problem that can cut a great day on the water short if you don’t know what’s happening. Essentially, the core of your propeller has broken loose from the blades, so all that engine power is just spinning the shaft without actually turning the prop.

The Inner Workings of a Propeller Hub

To really get what a spun hub is, you need to know that modern props are more than just a single hunk of metal. They're actually a three-part assembly designed to work together.

- The Outer Propeller Housing: This is the business end—the barrel and blades you see that grab the water and push your boat forward.

- The Inner Splined Hub: Tucked inside is a metal core with grooves, or splines, that slide right onto your prop shaft. This is what directly connects to your engine's power.

- The Rubber Bushing: Sandwiched between those two metal parts is a sleeve made of high-density rubber or a tough composite material.

This rubber bushing is the unsung hero of your lower unit. It acts as a shock absorber, a built-in failsafe to protect your expensive drivetrain components—gears, shafts, and seals—from the violent shock of hitting a rock, log, or shallow bottom. When you hit something hard, that rubber bushing is designed to give way, sacrificing itself to save you from a much, much more expensive repair bill.

Why a Hub Fails

A spun hub on propeller is what happens when that crucial bond between the rubber bushing and the metal parts gives up. The inner hub keeps spinning along with the prop shaft, but it breaks free and just spins uselessly inside the outer housing, which is stuck dragging through the water.

Sometimes this failure is instant and obvious after a major impact. Other times, it's a slow death. The rubber can degrade over years of heat cycles, constant shifting, and minor bumps, gradually losing its grip until it finally lets go completely. It’s like trying to use a stripped-out screwdriver—the handle turns, but the bit doesn't.

The tell-tale sign of a spun hub is a sudden, dramatic jump in your engine's RPM without any matching increase in speed. You’ll feel like you’ve been thrown into neutral, even though you’re still in gear.

This can be more than just annoying; it can be downright dangerous if you're trying to navigate a busy channel or get back to the dock in a stiff wind. You’ve got a perfectly good engine running, but none of that power is translating into thrust. Recognizing this symptom is the first step to diagnosing the problem and getting yourself moving again.

Recognizing the Telltale Signs of Hub Failure

When you're out on the water, knowing the difference between a spun hub and a more serious engine problem is absolutely critical. The symptoms can be sneaky at first, but they become impossible to ignore once you put the engine under any real load. Learning these signs will help you figure out what's wrong, right then and there.

The most classic indicator of a spun hub on a propeller is what we all call "slipping." You might just feel a little hesitation when you first hit the throttle. But when you push for more power to get on plane, that's when it really shows itself—the engine screams, but the boat just plows through the water, feeling disconnected and weak.

Sounds and Sensations of a Spun Hub

It’s not just about the lack of thrust; your ears and the seat of your pants will tell you a lot, too. A healthy drivetrain is pretty smooth, but a failing hub introduces a whole new set of unwelcome noises and vibrations.

Listen and feel for these specific symptoms:

- A Rattling or Clattering Noise: If the hub is completely shot, you might hear the inner splined core banging against the outer prop housing, especially at idle or low speeds. It's a distinct metallic rattle, not a deep engine knock.

- Weird Vibrations: A damaged hub can send some serious vibrations through the deck and right up into the steering wheel. This isn't the rhythmic pulse of a slightly bent prop blade; it feels more chaotic and seems to come from the very back of the boat.

- A Burnt Rubber Smell: Sometimes, the friction of that inner hub spinning wildly inside its rubber bushing can cook up a pretty unmistakable burning smell.

Pro Tip: The best way to think about it is like a manual car with a fried clutch. You can floor the gas pedal and the engine will roar, but the car barely creeps forward because that power isn't making it to the wheels. A spun hub is the exact same story for your boat.

Failure Under Load: A Real-World Scenario

Picture this: you're trying to pull a tuber. You gun it, the engine sounds like it’s giving it all it's got, but the boat just digs a trench in the water. The tuber sinks, the rope goes slack, and your tachometer is pinned while your GPS shows you’re barely moving. That’s a textbook case of a hub failing under load. Whatever little grip it had just isn't enough to overcome that extra drag.

This kind of situation really drives home why you need to diagnose the problem correctly. A spun hub, where the prop just spins free from the engine shaft, is a big deal. For commercial operators, these failures mean costly downtime and repairs, proving how even a small part can have huge consequences. Getting it diagnosed quickly and accurately is the first step toward a safe, affordable fix.

How to Inspect and Confirm a Spun Hub

So, you’ve felt the symptoms out on the water—the engine screams, but you’re going nowhere fast, and there’s a nasty vibration. It's time to roll up your sleeves and find out if a spun hub on the propeller is really the problem. A hands-on inspection is the only way to be 100% certain, and the first step is always safety.

Before you even touch the prop, make safety your top priority. Disconnect the battery and pull the key from the ignition. If you have a kill switch, unclip the lanyard. The absolute last thing you need is for that engine to kick over while your hands are anywhere near the propeller.

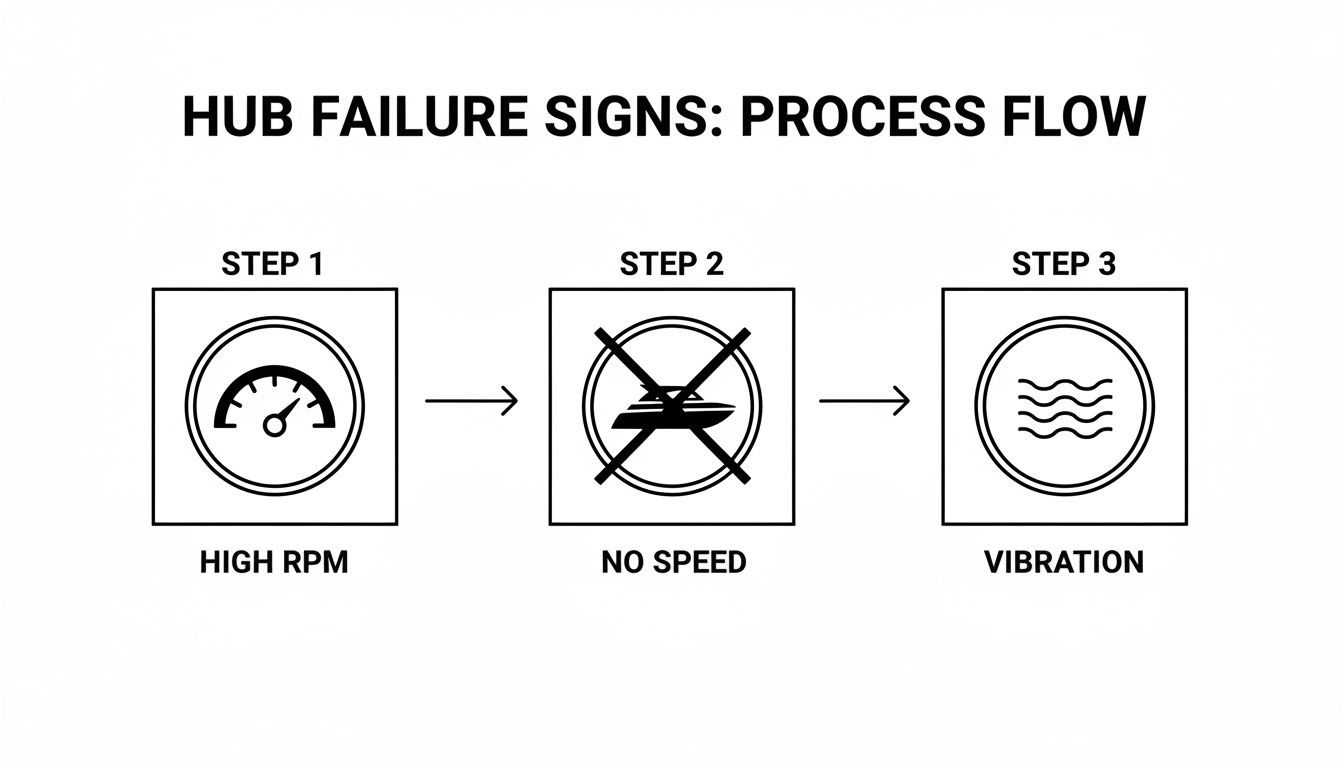

This diagram pretty much nails the connection between what you feel on the water and what's likely happening mechanically.

It lays out that classic story: high engine RPMs suddenly result in zero forward speed, often with a good shake, pointing a big finger right at hub failure.

The Definitive Marker Test

The simplest, most reliable way to confirm a spun hub is with a plain old marker. Make sure the engine is off and secured, then grab a permanent marker or a paint pen. Draw a straight line right across the back of the prop assembly. You want that line to go from the outer prop housing, across the rubber bushing, and onto the inner splined hub or the prop shaft nut.

With your mark in place, take the boat for a very short, controlled spin. Try to recreate what made you suspicious in the first place, like a quick burst of acceleration. You don't need to go far—just enough to put a load on the prop.

Now, pull the boat out and take a look at your line. If the hub has spun, that line will be broken. The part on the outer prop won't line up with the part on the inner hub anymore. That’s your smoking gun.

Visual and Physical Checks

Even without a marker, you can often spot a spun hub just by giving it a good look-over. Get up close and personal with the area where the rubber bushing is visible between the inner and outer metal parts of the hub.

- Extruded Rubber: Look for bits of black, melted, or pushed-out rubber squeezing from the hub. That's a dead giveaway that the bushing has failed from heat and friction.

- Excessive Play: Give the propeller a good wiggle. A tiny bit of movement forward and back along the shaft is okay, but you should feel zero rotational play. If you can twist the prop blades even a little bit without the prop shaft moving, the hub has definitely lost its grip.

A healthy propeller feels like one solid piece connected directly to the driveshaft. Any slop, rattling, or independent rotational movement is a major red flag that the internal bushing has failed.

For a final, foolproof check, grab a block of wood. Wedge a sturdy 2x4 between one of the prop blades and the anti-cavitation plate on your lower unit to lock the prop in place. Now, with the spark plugs removed to make it easier, try to turn the flywheel at the top of the engine by hand. If the engine turns but the prop stays put, you’ve just confirmed the hub is spun. Proper diagnosis is a huge part of good engine care, which you can read more about in our complete guide to outboard motor maintenance. This simple check takes all the guesswork out of it.

So, you've done the marker test and the verdict is in: you've got a spun prop hub. The next big question is what to do about it. Should you try to fix it, or is it time to just get a whole new propeller? Honestly, the right call comes down to what kind of prop you have, its overall condition, and how comfortable you are with a little wrenching.

For most folks running a standard aluminum prop, which is the vast majority of recreational boaters, just replacing the whole thing is the most practical choice. It's almost always faster, easier, and surprisingly, often cheaper in the long run.

Now, if you've invested in a nice stainless steel propeller, that's a different story. The goal here is usually to save that prop. They're not cheap, and a new hub is a much more palatable expense than a brand-new high-performance prop.

When to Repair the Hub

Fixing the hub, what we call "re-hubbing," means pressing out that old, failed rubber bushing and pressing a new one in. This is a fantastic option for more valuable props that are otherwise in good shape.

Think about a repair if:

- You're running a stainless steel prop. The higher price tag on these makes them the perfect candidates for a repair.

- Your prop blades are in great shape. If you don't have any major dings, bent edges, or chunks missing, re-hubbing makes a ton of sense.

- You've got a prop shop nearby. This isn't usually a DIY job. Re-hubbing needs a hydraulic press to get the new hub seated just right, and that's not something most of us have in the garage.

The biggest win with re-hubbing is saving a bunch of money on an otherwise expensive propeller. You get to keep a perfectly good (and pricey) set of blades in action without shelling out for a brand-new stainless prop.

But when it comes to aluminum props, the math just doesn't add up most of the time. The cost for a shop to press in a new hub can get awfully close to—or even cost more than—a whole new aluminum prop. If you're curious about why there's such a big difference, we break it down in our article on stainless steel versus aluminum props.

When to Replace the Entire Propeller

In a lot of cases, replacement is the clear winner, especially for the common aluminum props you see on most boats at the lake. It's often the simplest and smartest move.

You should definitely just buy a new prop if:

- You have an aluminum prop. The cost-benefit analysis almost always points to replacement.

- The prop has other issues. If the blades are already bent, chipped, or worn down, putting a new hub in a beat-up prop is just throwing good money after bad.

- You need a fast, simple fix. Swapping out the entire propeller is something you can do yourself in a few minutes with basic tools. No waiting on a shop, just back on the water.

Replacing the propeller also gives you a great opportunity to rethink your setup. Is your current pitch right for how you use the boat? A new prop could be a chance to boost your performance or fuel economy. For most boaters, the simplicity and guaranteed results of a fresh prop just make more sense.

Decision Guide: Repairing the Hub vs. Replacing the Propeller

Trying to weigh the pros and cons? It can get a little confusing, especially when you factor in costs, downtime, and the condition of your gear. This table should help clear things up and point you in the right direction.

| Factor | Repairing the Hub (Re-hubbing) | Replacing the Entire Propeller |

|---|---|---|

| Best For | High-value stainless steel props with blades in excellent condition. | Most aluminum props or any prop with blade damage. |

| Cost | Lower cost for expensive props ($75 - $150). Higher than a new aluminum prop. | Most cost-effective for aluminum props ($100 - $250). Higher cost for stainless steel. |

| DIY Friendliness | Difficult. Requires a hydraulic press and specialized knowledge. Usually a job for a prop shop. | Easy. A simple DIY job with basic hand tools that takes 15-30 minutes. |

| Downtime | Can take days or weeks depending on the prop shop's schedule. | Minimal. You can be back on the water the same day. |

| Outcome | Restores a high-quality prop to service. | A brand-new, perfectly balanced prop. Opportunity to change pitch. |

| Key Consideration | Is the rest of the prop worth saving? | Is the cost of a professional re-hub close to the price of a new aluminum prop? |

Ultimately, for aluminum props, replacement is the go-to solution. For a pristine stainless steel prop, a professional re-hubbing is the smart financial move. Use this guide to make the best call for your boat and your wallet.

A Practical Guide to Replacing Your Propeller

Whether you’re just swapping in a new hub kit or replacing the whole propeller, the job is pretty straightforward if you know what you're doing. Taking this on yourself is a great way to save some cash, and you'll get a much better feel for how your boat’s propulsion system really works. Honestly, with a few basic tools and a little bit of patience, you can handle this critical task with confidence.

First things first, though: kill the engine, pull the key from the ignition, and disconnect the battery. Safety is always the top priority around a prop.

Removing the Old Propeller

Getting that old, damaged prop off the shaft is your first hurdle. Look for the cotter pin—it's that small metal pin you see bent through the top of the prop nut. Grab a pair of pliers, straighten out the ends, and pull it right out. Here's a tip: never, ever reuse an old cotter pin. They’re a one-time-use safety item and cost pennies to replace.

Once the cotter pin is out, you can get to the prop nut. You'll need a prop wrench or a big socket wrench for this. To keep the prop from spinning as you're trying to loosen the nut, just wedge a block of wood between one of the blades and the anti-cavitation plate. It's a simple trick that gives you all the leverage you need without putting any strain on your lower unit.

After the nut comes off, the propeller should slide straight back off the splined shaft. Don't be shocked if it's a bit stubborn. Behind it, you'll see the thrust washer, a thick washer that handles the forward force from the prop. Make sure you don't lose this piece; it's critical for proper spacing and alignment.

Installing the New Propeller

Getting the new prop on correctly is just as important as diagnosing the problem in the first place. A job done right here will save you from future headaches on the water.

Pro Tip: Before you slide that new prop on, slather a good quality waterproof marine grease all over the propeller shaft splines. This is a crucial step that keeps the prop from seizing onto the shaft from corrosion, and you'll thank yourself the next time you have to take it off.

Slide the thrust washer back on first, making sure it sits flush against the gearcase housing. Then, guide your new propeller onto the splines until it bottoms out against that thrust washer. It should feel solid, with no wobble at all.

Next up is the prop nut. Tighten it down firmly with your wrench, but don’t go crazy with it. Your engine's service manual will have the exact torque spec. The general rule of thumb is to get it snug, then tighten it just a little more until the grooves in the nut line up with the hole in the prop shaft for the cotter pin.

The final touch is inserting a brand-new cotter pin through the hole and bending the ends securely around the nut. That little pin is the final failsafe that keeps your prop nut from backing off and leaving you stranded.

If you’re taking this opportunity to upgrade, our guide on selecting a propeller can walk you through making sure you’ve got the right match for your boat. Getting the selection right is a big part of avoiding future problems in the first place.

Preventative Care to Avoid Future Hub Failure

Dealing with a spun prop hub is one of those headaches that can absolutely torpedo a great day on the water. Nobody wants that. The good news is, with a little foresight and a few good habits, you can stop most hub failures before they ever start.

The biggest enemy of your propeller hub is, without a doubt, impact. Every time you run through shallow, debris-filled water, you’re rolling the dice. Smacking a submerged log, a rock, or even just churning through a hard sandbar sends a massive shockwave right up the drivetrain. Your hub is designed to be the sacrificial lamb in that scenario, saving your gears from catastrophic damage.

Make Prop Inspections Part of Your Routine

You wouldn’t launch without checking your oil, right? Your prop deserves the same attention. A quick once-over before you leave the dock and after you pull the boat can make all the difference.

- Look for Dings and Damage: Even a small nick or a slightly bent blade can throw the whole prop out of balance. This creates a constant, subtle vibration that, over time, fatigues the rubber in the hub until it finally gives up.

- Check for Wear and Tear: If you spend a lot of time in sandy or silty water, your blades will slowly wear down and lose their sharp edge. This forces the engine to muscle through the water, putting a ton of extra strain on the hub.

- Confirm a Snug Fit: Double-check that your prop nut is torqued down correctly and secured with a fresh cotter pin. A loose propeller creates its own nasty vibrations that can wreck a hub in a hurry.

I can't stress this enough: taking just five minutes to give your prop a good look can be the difference between a great day and being stranded miles from shore. Catching minor damage early means you can get it repaired before it turns into a complete hub failure.

Match Your Prop to Your Boat

This is one of the most overlooked parts of keeping your hub healthy. You need to make sure your propeller has the right pitch for your specific boat and engine combo.

If the pitch is wrong, your engine is either going to over-rev or lug under the strain. Both scenarios put a ton of stress on the entire drivetrain, and the hub takes a lot of that abuse. A properly matched prop lets your engine run in its sweet spot—that ideal RPM range—which means smooth power and a much longer life for all your components.

Of course, taking care of your prop hub is just one piece of the puzzle. Keeping your whole vessel in top shape is the real key to worry-free boating. Following our boat maintenance checklist is a fantastic way to build a solid routine. For an even deeper dive, it's always a good idea to consult a comprehensive boat maintenance checklist from other experts, too. Simple, consistent habits are what keep you on the water and out of the repair shop.

Spun Propeller Hubs: Your Questions Answered

Even with a solid understanding of what a spun hub is, you've probably still got a few questions. It’s one of those common boating problems that can feel pretty mysterious the first time it happens to you. Let's clear up some of the most frequent questions we get from boaters dealing with this exact issue.

Can I Actually Get Back To The Dock With a Spun Hub?

Yes, but you'll need to be incredibly careful and patient. A spun hub rarely fails completely in one catastrophic moment. More often than not, it can still grip just enough to give you a tiny bit of thrust at idle or just above. Boaters often call this "limp mode."

If you find yourself in this situation, here’s how to handle it:

- Keep your RPMs at rock bottom. I'm talking just enough to make slow, steady headway.

- No sudden throttle changes. Any quick burst of power will just make it slip. Smooth and easy does it.

- Settle in for a long ride. This will be a slow, and frankly, frustrating trip back to the ramp.

Trying to push the engine will only make the hub slip more, which generates a ton of heat and could finish it off for good. The name of the game is getting back safely, not setting any speed records.

Will a Spun Hub Wreck My Engine or Lower Unit?

Here's the good news: the hub is actually designed to be the weak link in your drivetrain. Its entire job is to fail before you do catastrophic damage to the expensive gears, shafts, and other critical components inside your lower unit. Think of it as a mechanical fuse.

So, while the vibrations from a slipping hub aren't great for your engine's health, the hub is essentially sacrificing itself to protect the really pricey parts.

That said, you should absolutely not keep running the boat with a known spun hub, especially at higher speeds. The excessive vibration and an unbalanced prop can put a ton of unnecessary stress on your seals and bearings over the long haul.

A spun hub is your boat’s way of telling you to stop and fix the problem. While it's not likely to cause an immediate, catastrophic engine failure, ignoring it is just asking for a bigger, more expensive headache later on.

What's This Going To Cost Me To Fix?

The repair cost really depends on your propeller type and how you decide to tackle it.

For the vast majority of boaters running standard aluminum props, the simplest and most cost-effective route is just to replace the whole propeller. You can usually find a new aluminum prop for anywhere between $100 and $250.

Now, if you're running a pricier stainless steel prop, you'll want to look into a professional "re-hubbing" service. This process typically runs between $75 and $150, which is a fantastic deal when a new stainless prop can easily set you back over $500. Don't forget to grab a new cotter pin and some quality marine grease—they're small but absolutely essential for doing the job right.

At Better Boat, we know that having the right tools and supplies makes any maintenance task easier. From waterproof marine grease to a full lineup of boating accessories, we have everything you need to tackle a propeller swap and get back on the water with confidence. Explore our collection of boating essentials today!