Anchor holder for boat: A Complete Guide to Choosing & Installing

Let’s be honest, an anchor isn't just a hunk of metal—it's your boat's parking brake on the water. But without a proper anchor holder for boat security, that essential tool can quickly become a clumsy, deck-scarring liability. A dedicated holder transforms your anchor from a problem into a ready-to-deploy asset, streamlining the entire process and making your boat a whole lot safer.

Why a Dedicated Anchor Holder Is a Boating Essential

Leaving a heavy anchor sliding around on deck is just asking for trouble. In anything but the calmest seas, it becomes a serious trip hazard. Worse yet, it’s a surefire way to damage your gelcoat, leaving behind deep scratches, chips, or even cracks that are a pain (and expensive) to fix. An unsecured anchor could even decide to take a swim on its own, taking your pricey rope and chain along with it.

A good anchor holder puts a stop to all that by giving your anchor a designated, secure home. This isn't just about being tidy; it's about fundamental safety and making your life easier on the water. By locking down that anchor, you instantly make your deck a safer place to be.

Enhancing Safety and Accessibility

When you need to drop anchor, you often need to do it now. The last thing you want is to be fumbling around. A well-placed holder keeps your anchor ready for immediate and controlled deployment. This is absolutely critical when you need to set anchor in a hurry to hold your position or in an emergency.

Instead of wrestling a heavy anchor out of a storage locker, it's right there, ready to go. This simple change turns anchoring from a two-person struggle into a straightforward, one-person job. A good system also makes retrieval a breeze, guiding the anchor back into its housing without it banging against your hull. To see how all the pieces fit together, check out our complete guide on the modern boat anchor system.

Protecting Your Investment

Beyond keeping everyone on board safe, an anchor holder protects the boat itself. Every time an anchor clanks against the fiberglass, you risk cosmetic and structural damage. A holder, especially a bow roller style, ensures the anchor is deployed and retrieved without ever touching the hull.

Think of a dedicated anchor holder not as an optional accessory, but as an essential piece of equipment. It prevents costly gelcoat repairs, eliminates major safety hazards, and makes one of the most critical boating tasks easier and more reliable.

It’s no surprise that as more people get into boating, the market for quality gear is growing. The global boat anchors market was valued at $2,725.31 million in 2021 and is on track for major growth. This trend, highlighted by market analysts at dataintelo.com, just goes to show how many boaters are prioritizing a complete and secure ground tackle setup.

Matching the Right Anchor Holder to Your Vessel

Let’s get one thing straight: the perfect anchor holder for a zippy 17-foot center console is going to be completely wrong for a 42-foot cruiser. This isn't a one-size-fits-all situation. The right choice boils down to your boat's specific design, the type of anchor you're using, and how you actually spend your time on the water. Get this match right, and you’ll have a system that’s safe, reliable, and just plain works.

Your first decision point is the material. If you boat in saltwater, don’t even think about it—go with marine-grade 316 stainless steel. Its ability to fend off corrosion is unmatched, and it's an investment that pays for itself by standing up to the relentless abuse of salt and spray. For smaller boats that only ever see freshwater, you might get away with a heavy-duty polymer, which can be a decent lightweight and budget-friendly option.

Common Styles of Anchor Holders

Once you’ve settled on the material, you need to pick a style. Each design has its own job to do and is built for different boats and anchoring situations. Knowing the real-world pros and cons of each one is what will help you make a smart decision.

- Bow Rollers: This is hands-down the most popular setup, and for good reason. Bolted right to the bow, a roller gives your anchor a smooth runway to deploy and come home without chewing up your hull. It’s the go-to choice for most V-hull boats and is practically a necessity if you're wrestling a heavy plow or delta-style anchor.

- Pulpit Mounts: Think of these as a bow roller that's built right into a bow pulpit—that platform at the very front of the boat. You get all the same benefits, but it's designed for boats that already have a pulpit, creating a really clean, integrated look.

- Transom Brackets: Not every anchor belongs on the bow. For a secondary or stern anchor, a transom bracket is a fantastic solution. It's perfect for holding your boat steady in a current or keeping it from swinging all over the place. Plus, it keeps your stern clear and the anchor ready to go at a moment's notice.

- Rail Mounts: Got a jon boat, dinghy, or inflatable where every square inch of deck space is prime real estate? A rail mount is your best friend. These clever holders clamp right onto the boat’s rail, getting the anchor up and out of the way without having to drill a single hole.

Of course, the holder is just one piece of the puzzle. It has to be paired with the right anchor for your boat’s size and weight. If you're scratching your head about what your boat needs, we've got you covered in our guide which includes a helpful boat anchor size chart.

Remember, the goal is to create a complete system. The holder should not only fit your boat but also be appropriately rated for the weight and style of the anchor it will carry, especially in rough conditions.

To help you sort through the options, I’ve put together a quick comparison of the most common anchor holder types you’ll run into.

Anchor Holder Type Comparison

This table breaks down the most common styles to help you see, at a glance, which one might be the best fit for your setup.

| Holder Type | Best For (Anchor Style) | Common Material | Pros | Cons |

|---|---|---|---|---|

| Bow Roller | Plow, Delta, Claw | 316 Stainless Steel | Protects hull, simplifies deployment | Requires deck space, permanent install |

| Pulpit Mount | Plow, Delta | 316 Stainless Steel | Integrated look, excellent leverage | Only for boats with a bow pulpit |

| Transom Bracket | Fluke, Danforth | Stainless Steel, Polymer | Great for secondary anchors | Less common for primary anchoring |

| Rail Mount | Small Fluke, Grapnel | Polymer, Aluminum | Saves deck space, no drilling required | Not suitable for heavy anchors |

Choosing the right holder ultimately comes down to matching the hardware to your boat and your anchor. Take a minute to think about how you use your boat, and the choice will become a lot clearer.

Installing Your Anchor Holder for Maximum Strength

An anchor holder that's just slapped on is a serious liability, not a help. Think about it: that thing has to take the incredible force of an anchor getting tossed around in heavy seas. Getting the installation right isn't just a suggestion—it's absolutely critical to creating a bond between the holder and your boat that's strong, waterproof, and built to last.

Before you even think about picking up a drill, the most important call you'll make is where to mount it. You're looking for a spot with serious structural integrity, because the forces at play here are immense. Hunt for flat, solid areas on the bow, stern, or rail, and always, always check what's on the other side. Steer clear of spots with complex curves or flimsy, unreinforced fiberglass.

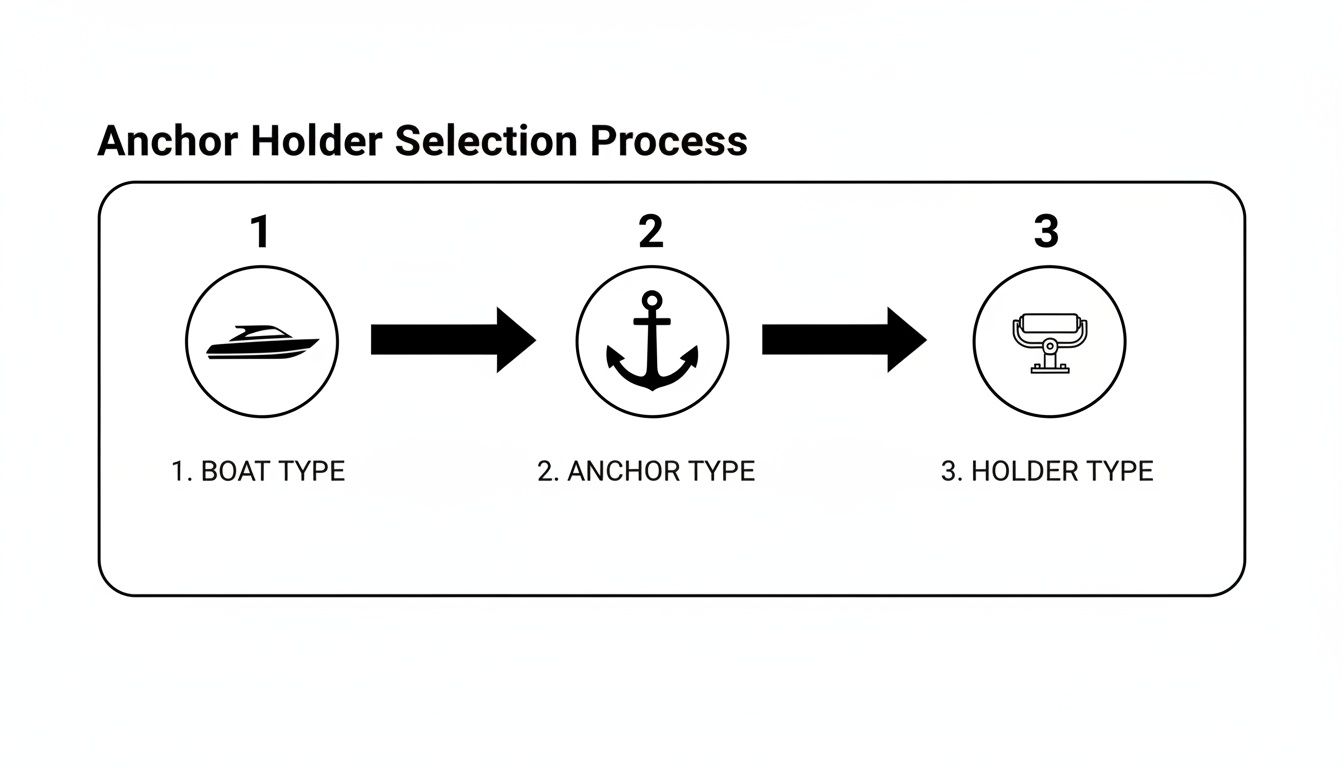

This is a good time to step back and look at the big picture of how all these pieces fit together.

This simple flow—boat to anchor to holder—is really the foundation for a ground tackle system you can trust.

Gathering Your Tools and Materials

There’s nothing worse than having to stop mid-project to frantically search for the right tool or part. A sloppy installation often starts right there. Get everything you need lined up before you start, and the whole job will go a lot smoother.

Here's a quick checklist for a pro-level job:

- Drill with sharp bits: You’ll need a smaller one for pilot holes and another for the final bolt size.

- Top-shelf marine sealant: Our Marine Sealant & Adhesive creates a permanent, waterproof bond you can count on.

- Stainless steel hardware: Every single bolt, nut, and washer needs to be 316-grade stainless steel. Don't compromise here; it’s your best defense against corrosion.

- Backing plates: These are non-negotiable. They spread the load across the fiberglass, preventing stress cracks and pull-through.

- Wrenches and a socket set: For getting all the hardware properly tightened down.

- Masking tape: Perfect for marking your drill spots and protecting the gelcoat from chipping.

- Acetone or denatured alcohol: You'll need this to clean the surfaces perfectly before you apply any sealant.

The Installation Process Step by Step

Alright, you've scouted the perfect location and your tools are ready to go. It's time to get this holder mounted.

Set the holder in its final position and use a pencil to carefully trace the mounting holes. Now, here's a great little trick: apply masking tape over those marks. It does a fantastic job of preventing the gelcoat from chipping when the drill bit bites in.

Always start with small pilot holes, then switch to the final bit size for your bolts. For an even cleaner finish and to further protect your gelcoat, chamfer the edges of the drilled holes. You can do this by just touching them lightly with a larger drill bit or a dedicated countersink tool.

The real secret to a rock-solid installation isn't just about the bolts—it's the backing plate. This piece of stainless steel or marine-grade plywood sits on the underside of your mounting surface. It dramatically distributes the stress and is what keeps the bolts from ripping right through the fiberglass when things get rough.

Before you put it all together, give the mounting surface and the bottom of the anchor holder a thorough wipe-down with acetone. Apply a generous bead of marine sealant around each hole and across the base of the holder.

Push the bolts through, get the backing plate in position on the underside, and then tighten the nuts until they're snug. Go easy here. If you overtighten, you’ll squeeze out all the sealant and risk cracking the gelcoat.

Once everything is tightened, clean up any excess sealant that oozed out. This gives you a clean, professional finish. Now for the hard part: let the sealant cure completely according to the manufacturer's instructions before you put any load on it.

For a look at how different styles mount up, you can find a solid overview of various anchor brackets for boats that might give you some ideas.

Integrating Your Holder with Your Anchor Rode and Chain

A top-notch anchor holder is the foundation of your ground tackle system, but it’s really only one piece of a bigger puzzle. For everything to work right, your holder, anchor, rode, and chain need to operate like a single, well-oiled machine. This isn't just about being secure at anchor; it's about smooth and safe deployment and retrieval, every single time.

You've got to think of these parts as a team. The rode, which is usually a nylon rope, gives you that crucial stretch needed to absorb the shock from waves and wind gusts. But let's be honest, nylon gets shredded easily by rocks, sharp shells, or coral on the seabed. That’s where the anchor chain steps in to save the day.

The Critical Role of the Anchor Chain

An anchor chain is non-negotiable for two main reasons. First, its weight is what keeps the anchor shank lying flat against the seabed. This allows the flukes to dig in properly and set firm. Just as important, though, is that it acts as a tough, abrasion-proof leader, protecting your nylon rode from getting chewed to bits.

A solid rule of thumb is to have at least one foot of chain for every foot of boat length. This gives you enough weight and protection for most situations you'll encounter. The connection between your rope and chain needs to be bombproof. A professionally done rope-to-chain splice is the gold standard because it’s incredibly strong and glides smoothly over a bow roller without snagging.

You can't skimp on chain quality. It's so vital that the global market for it is booming, with projections showing the boat anchor chain market will hit $2.1 billion by 2025. This growth is all about the increasing demand for safety and reliability. Modern touches like hot-dip galvanizing can even extend a chain's life by up to 30%, saving you money in the long run.

Securing the Anchor for Travel

Once you've hauled the anchor back up and it’s sitting snugly in its holder, you absolutely have to lock it down. An anchor bouncing around in a bow roller while you're underway in choppy seas puts a massive strain on the holder, the deck, and even your windlass. Plus, the constant banging and clanking will drive you crazy on a long trip.

Your ground tackle system is only as strong as its weakest link. Ensuring your anchor is securely locked in its holder while underway is just as important as ensuring it holds fast on the bottom.

To stop the bouncing, you need a way to pin that anchor down tightly. Here are a few tried-and-true methods:

- Safety Chains or Wires: A short piece of chain or stainless steel wire with a snap shackle is perfect for lashing the anchor shank to a nearby cleat or right to the holder itself.

- Anchor Tensioners: These are purpose-built gadgets that use a lever or turnbuckle to apply serious downward pressure on the anchor shank, locking it firmly into the roller.

- Rope Lashing: If you're in a bind, a sturdy piece of rope tied with a trucker’s hitch can cinch the anchor down surprisingly well.

Making sure your anchor is properly secured means it'll be right where you left it, ready to go, no matter what the sea throws at you on the way to your next spot. For a deeper dive into picking the right gear, check out our complete guide on choosing the correct boat anchor chain.

Simple Maintenance for Long-Term Reliability

The marine environment is brutal. There’s really no other way to put it. Saltwater, constant sun, and moisture relentlessly attack every piece of hardware on your vessel. Your anchor holder is no exception.

If you neglect its upkeep, you're setting yourself up for corrosion, mechanical failure, and some pretty costly repairs down the line. A simple, proactive maintenance plan is your best defense against the elements and ensures your holder operates flawlessly when you need it most.

After every single trip, especially in saltwater, give the entire holder a thorough freshwater rinse. Honestly, this one step is the most effective thing you can do. It combats the salt buildup that is the primary driver of corrosion on stainless steel and other metals.

Your Routine Inspection Checklist

Beyond a quick rinse, a hands-on inspection every few outings can help you catch problems early. It only takes a few minutes, but the peace of mind is worth it.

- Check Hardware Tightness: Grab a wrench and give every mounting bolt and nut a quick check. The vibrations from being underway can easily cause hardware to loosen over time.

- Inspect for Stress Cracks: Look closely at the gelcoat around the base of the anchor holder. Those fine, spiderweb-like cracks can be a red flag for excessive stress on the fiberglass.

- Examine Moving Parts: If you have rollers, pins, or hinges, check them for smooth operation. Any stiffness or grinding is a sure sign that some lubrication is needed.

This same attention to detail applies to all ground tackle. You’re dealing with a massive and vital market here—ship anchors and their holders support a multi-billion-dollar industry where reliability is everything.

We’re seeing innovations that are cutting anchor weight by 20% while doubling holding power, a critical advance as global vessel numbers push past 100,000. It just goes to show how every single anchor holder plays a role in preventing billions in potential losses from drift incidents. You can learn more about this vital market from the full market report.

Cleaning and Lubrication Tips

Regular cleaning doesn't just keep your holder looking sharp; it genuinely extends its life. For stainless steel, you might sometimes see small orange spots of surface rust appear.

Don't panic if you see minor surface rust on your stainless steel holder. This is often just a surface deposit and can be easily removed with a quality metal polish, restoring the protective chromium oxide layer.

Use a soft cloth and a gentle cleaner specifically designed for marine metals. After cleaning, applying a thin coat of our Marine Wax can provide an extra layer of protection against the harsh elements.

Finally, a small dab of waterproof marine grease on rollers, pins, and any other moving parts will keep them operating freely. This simple step prevents them from seizing up when you least expect it.

Got Questions About Your Anchor Holder? We've Got Answers.

Even the most seasoned boaters run into questions when sorting out their ground tackle. Getting your anchor holder for boat security right is a big deal, and the details matter. Let's walk through some of the most common things people ask, so you can feel confident you're making the right call.

Can I Install This Myself?

This is usually the first question on everyone's mind. For most boaters who are comfortable with a drill and a wrench, installing an anchor holder is absolutely a doable weekend project.

The number one thing to get right is making sure your mounting spot is rock-solid. This almost always means installing a backing plate to spread the load and prevent stress cracks. Don't skimp here—always use marine-grade stainless steel hardware and a top-shelf marine sealant for a waterproof seal that will last.

That said, if you're looking at your deck and have any doubt about the structural support, or if the idea of drilling holes in your boat gives you cold sweats, call in a pro. A marine technician can get it done right, and it's a small price to pay to avoid a very expensive mistake.

Choosing the Right Materials and Size

Another frequent hang-up is picking the right material and size. It can feel a bit overwhelming, but it's simpler than you think.

For anyone boating in saltwater, there's only one real choice: 316 marine-grade stainless steel. It's the gold standard for a reason. Its resistance to corrosion is second to none, and it has the strength to handle serious abuse. Yes, it costs more initially, but it's an investment that pays for itself by not having to replace it later.

If you're strictly a freshwater boater on a smaller vessel, you might get away with a high-impact polymer holder. They're a budget-friendly option, but just know they will not hold up to the harshness of a saltwater environment.

Getting the size right is just as critical. Here's the key: size your holder to your anchor's style and weight, not the length of your boat.

Always start with the manufacturer's guidelines. They'll tell you exactly which anchor types (like Danforth, Plow, or Claw) and weight ratings are compatible. An undersized holder is a serious weak link in rough seas.

Here's a pro tip: choose a holder that's rated for an anchor slightly heavier than the one you actually use. This gives you a crucial safety buffer for the dynamic loads that happen when your boat is pitching and rolling. You also want to make sure the roller is wide enough for your anchor's shank so it doesn't get jammed up. Nail these details, and you'll have a setup you can truly depend on.

At Better Boat, we know that a secure anchor starts with the right equipment. Our full line of anchoring and trailering gear is designed with the durability and reliability you need for peace of mind on the water. Explore our high-quality solutions today at https://www.betterboat.com.