Choosing Your Boat Anchor Rope A Complete Guide

Think of your boat's anchor rope as its lifeline. It’s the single most important connection between your vessel and the solid ground of the seafloor, providing critical safety and security when conditions get unpredictable.

This isn't just any old rope we're talking about; it's a vital piece of your entire anchoring system. For almost any boater, the best setup isn’t just rope, but a combination of rope and chain known as an anchor rode. This combo gives you the best of both worlds: shock absorption and serious durability.

Why Your Anchor Rope Is Your Most Critical Connection

Choosing the right anchor rope is a bit like a mountaineer picking their climbing rope. You wouldn't trust a thin, static cord to catch a dynamic fall, right? The same logic applies on the water. A one-size-fits-all approach to your anchor rode is just asking for trouble. Everything—the material, the construction, the length—has to be a perfect match for your boat’s size, weight, and the kind of conditions you plan to face.

This is the link that keeps you from drifting onto the rocks, into a busy shipping channel, or away from that perfect fishing spot you just found. It's the unsung hero that quietly battles wind, waves, and current. Getting this right isn’t about convenience; it’s fundamental to safe boating.

The Role of the Anchor Rode

The term "anchor rode" refers to the entire line that connects your anchor to your boat. It’s almost never just rope. A proper setup has two key parts working together:

- The Chain: A length of heavy chain connects directly to the anchor itself. Its weight is crucial because it helps the anchor dig into the seabed at the right horizontal angle, giving it maximum holding power. It also provides fantastic protection against abrasion from rocks and debris on the bottom.

- The Rope: The rope section is what connects the chain to your boat. Its main job is to provide length and, most importantly, shock absorption. This elasticity prevents sudden, sharp jerks from yanking a well-set anchor right out of the bottom.

This two-part system is both incredibly strong and surprisingly forgiving. You can dive deeper into how all these pieces work in tandem in our complete guide to the boat anchor system.

Understanding Core Rope Materials

The material your anchor rope is made from dictates how it performs under pressure. Just like different fabrics have their own unique qualities, so do marine ropes. You'll mainly run into three materials: Nylon, Polyester, and Polypropylene, and each has clear pros and cons.

A well-designed anchor rode acts like a spring, absorbing the energy of wind and waves. Without this elasticity, every surge would transfer directly to the anchor, risking a sudden and dangerous break in its hold.

Nylon is the undisputed king of anchor rodes, and for good reason. Its superpower is its ability to stretch—up to 40% of its length under load without breaking. This elasticity is an absolute game-changer in choppy water. When a wave lifts your boat, a nylon rope stretches to absorb the shock, then gently contracts as the boat settles. This smooths out the ride and dramatically cuts down on the peak strain put on your anchor and deck hardware.

Polyester, on the other hand, has very little stretch. While it's strong and has great UV resistance, that rigidity makes it a poor choice for a primary anchor line. It’s much better suited for things like halyards on a sailboat where you want as little stretch as possible. Polypropylene is light and it floats, but it’s weaker than nylon and breaks down quickly in the sun, making it completely unsuitable for the tough job of anchoring.

Getting a handle on these basic material differences is the first step toward building an anchoring setup you can truly rely on.

Decoding Anchor Rope Materials and Construction

Picking the right anchor rope is a bit like choosing tires for your car. The stuff it’s made of and how it’s put together directly impact performance, safety, and how long it’ll last. Not all ropes are created equal, and knowing the difference is what keeps you securely anchored when the wind picks up.

The choice you make here affects how well your whole anchor system handles shocks from waves and wind. Get it right, and your anchor stays dug in. Get it wrong, and it can get yanked right off the seabed. Let’s break down the common materials and construction styles to find the perfect fit for your boat.

Think of this as an investment in your safety and peace of mind. Globally, the anchor rope market is already worth about $1.6 billion, and it's growing. Modern materials like braided nylon and tough polyester blends have even extended rope lifespans by up to 30%, which means less frequent replacements and more money in your pocket.

The Best Materials for Your Anchor Rode

While you'll see a few different synthetic fibers out there, the conversation for anchor lines really comes down to one clear winner: Nylon. Its ability to stretch and absorb energy is exactly what you need.

-

Nylon: This is the undisputed champ for anchor ropes. Why? Because it stretches—a lot. Good quality nylon can stretch up to 40% of its length without failing, which makes it a phenomenal shock absorber. When a big wave or a strong gust of wind hits your boat, a nylon line stretches to soak up that energy instead of transferring a sudden, violent jolt to your anchor and deck cleats.

-

Polyester: It’s strong and stands up great to UV rays and abrasion, but polyester has almost no stretch. That rigidity makes it perfect for things like sailboat halyards where you want zero give, but it’s a terrible choice for an anchor line where that shock absorption is non-negotiable.

-

Polypropylene: This stuff is cheap, light, and it floats, which might sound good on the surface. But it’s much weaker than nylon and gets destroyed by sunlight in a hurry. It has its uses, but you should never trust it for something as critical as your anchor line.

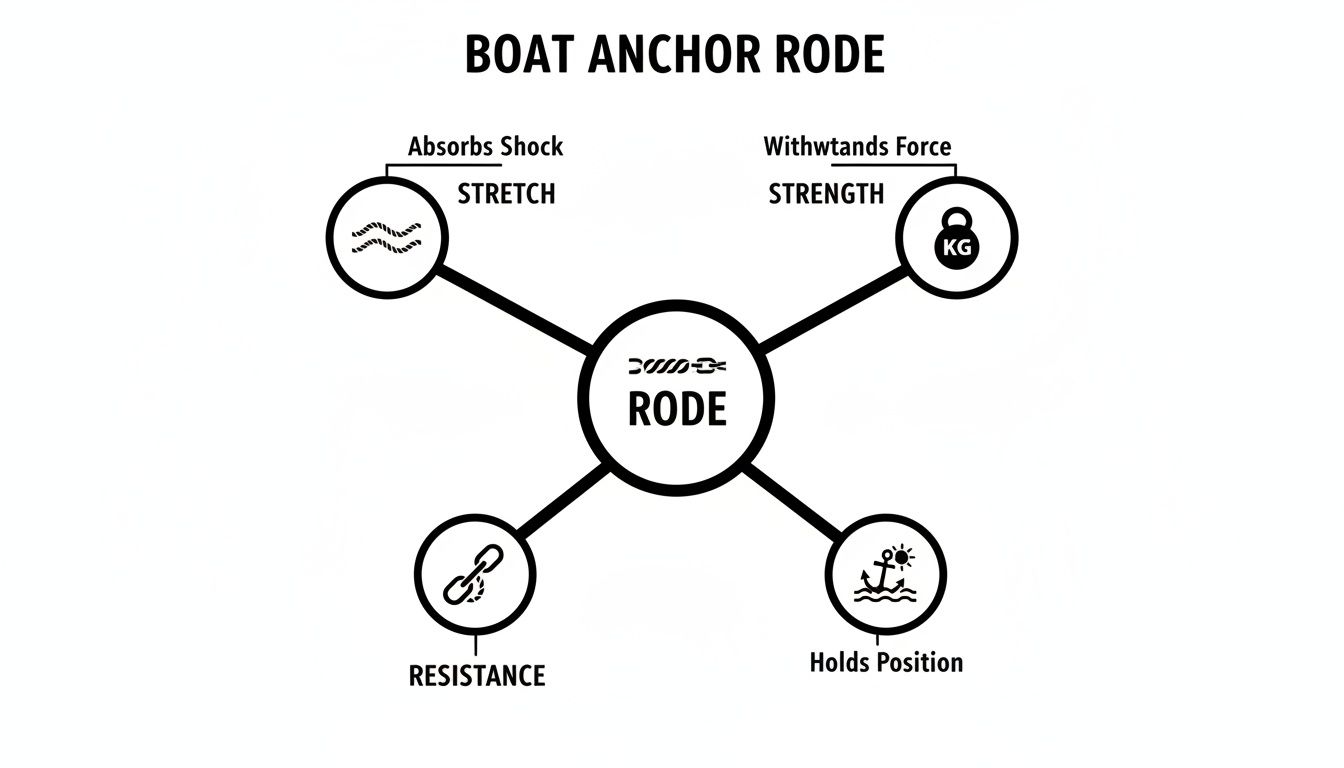

This diagram really helps visualize the key properties you're looking for in a reliable anchor rode.

It’s all about finding that perfect balance of stretch, strength, and resistance to handle the dynamic forces you’ll encounter on the water.

Exploring Anchor Rope Construction

Material is only half the story. The way a rope is built—its construction—plays a huge role in how it feels in your hands, how durable it is, and how easily it works with your gear. You’ll generally run into three main types.

3-Strand Twisted Rope

Think of 3-strand as the old-school, reliable classic. It’s exactly what it sounds like: three thick strands twisted together to form a strong, no-frills, and budget-friendly line.

One of the best things about 3-strand rope is how easy it is to splice. Splicing an eye or attaching a thimble is a skill almost any boater can pick up with a few basic tools, making it a favorite for the DIY crowd. The trade-off is that it can be a bit rough on the hands and has a tendency to kink up if you're not careful.

Double-Braid Rope

This is the modern workhorse. Double-braid rope has a braided inner core protected by a braided outer cover, creating a line that’s incredibly strong, smooth, and flexible. It runs beautifully through windlasses and bow rollers without snagging.

It's much more comfortable to handle and coils neatly without kinking up. The only real catch is that splicing it is a more involved process than with 3-strand, often requiring special tools and a bit of practice to get right.

8-Plait Rope

Also called square-laid rope, 8-plait is made of eight strands woven together in a square pattern. The result is a rope that's exceptionally flexible and strong, and it flakes down into an anchor locker beautifully without tangling.

It kind of combines the best qualities of the other two—great flexibility and serious strength—but it usually comes with a higher price tag. If you're looking to learn more about rope in general, you can dig into the details of how different types of marine rope are used for various jobs on board.

Boat Anchor Rope Material and Construction Comparison

This quick-reference table breaks down the key differences between the most common types of nylon anchor rope to help you see which one might be the best fit for you.

| Feature | 3-Strand Nylon | Double-Braid Nylon | 8-Plait Nylon |

|---|---|---|---|

| Strength | High | Highest | Very High |

| Stretch/Shock Load | Excellent (best for absorbing shock) | Very Good | Excellent |

| Handling | Can be rough on hands; prone to kinking | Very smooth and flexible; easy on hands and coils neatly | Extremely flexible and supple; lays flat in anchor locker with no tangling |

| Ease of Splicing | Very easy; can be done with basic tools | Difficult; requires specialized tools and practice | Moderately difficult; easier than double-braid but harder than 3-strand |

| Abrasion Resistance | Good | Very Good (braided cover protects the core) | Excellent (flat profile resists chafe well) |

| Cost | Most affordable option | More expensive than 3-strand | Typically the most expensive option |

| Best For | All-purpose anchoring, budget-conscious boaters, those who prefer to DIY splice | Boats with windlasses, boaters wanting smooth handling and high strength | Boaters with deep anchor lockers who need a rope that won't tangle, premium setups |

Ultimately, whether you choose the classic 3-strand, the smooth-handling double-braid, or the super-flexible 8-plait, you're making a solid choice as long as it's high-quality nylon. Your decision will likely come down to your budget, your boat's equipment (like a windlass), and your personal preference for handling.

Getting Your Anchor Rope Size and Scope Right for Safety

When you drop anchor, you’re putting a whole lot of trust in a system held together by simple physics. Nailing the math isn't just a good idea—it's one of the most fundamental parts of staying safe out on the water. Two numbers are absolutely critical here: the diameter of your boat anchor rope and how much line you let out, which we call scope.

Think of your anchor rope's diameter as its backbone. If it’s too thin for your boat's size and weight, it becomes a serious weak link, ready to snap under the strain of a stiff wind or choppy waves. On the other hand, a rope that's way too thick is just a pain to handle and a waste of money.

Finding the Right Rope Diameter

Don't worry, you don't need a degree in marine engineering to get this right. Boaters have been using a simple, trusted rule of thumb for ages, and it’s a perfect starting point for picking the right rope.

Here’s the guideline: use 1/8 inch of rope diameter for every 9 feet of boat length.

Let's say you have a 27-foot boat. Just divide 27 by 9, which gives you 3. Then, you multiply that by 1/8 inch, and you get 3/8 inch. It's a straightforward calculation that ensures your rope has the muscle to handle the loads your boat will throw at it.

To make things even simpler, here's a quick-glance table to help you match your boat's length to the correct rope diameter.

Recommended Anchor Rope Diameter by Boat Length

This table provides the minimum recommended rope diameter for your boat's overall length. It's a great way to quickly confirm you're on the right track.

| Boat Length | Recommended Rope Diameter |

|---|---|

| Up to 20 feet | 3/8 inch |

| 21 to 27 feet | 3/8 inch |

| 28 to 35 feet | 1/2 inch |

| 36 to 44 feet | 5/8 inch |

| 45 to 55 feet | 3/4 inch |

Always remember that these are general guidelines. If you frequently anchor in rough conditions or have an unusually heavy boat for its length, sizing up is a smart move.

Understanding and Calculating Scope

Once you've got the right size rope, the next make-or-break decision is figuring out how much of it to let out. This is where "scope" comes into play. Scope is simply the ratio of your anchor rode's length to the vertical distance from your bow down to the seabed.

A higher scope ratio means you're pulling on the anchor more horizontally, which helps it dig in and really bite into the bottom. A low scope pulls the anchor upwards, and that's a surefire way to have it pop right out.

On a calm, sunny day, a scope of 5:1 is the absolute minimum you should consider. That means for every one foot of depth, you let out five feet of line. But when the wind picks up or the seas get choppy, you'll want a much safer ratio of 7:1 or even 10:1.

The formula for figuring out how much rope you need is:

(Water Depth + Bow Height) x Scope Ratio = Total Rode Length

Let’s walk through a real-world example. Imagine you have a 30-foot boat and you're anchoring in 20 feet of water. The distance from your bow to the water is about 4 feet. There’s a bit of wind in the forecast, so you decide a safe scope of 7:1 is the right call.

- Step 1: Add the depth of the water to your bow height: 20 ft + 4 ft = 24 ft.

- Step 2: Now, multiply that total vertical distance by your scope: 24 ft x 7 = 168 ft.

So, in this situation, you'd need to pay out at least 168 feet of anchor rope to be secure. And don't forget, the right anchor size is just as critical as the rope. To find the perfect match for your vessel, check out this handy boat anchor size chart.

For those managing rental fleets or maintaining boats professionally, it’s vital to use quality rope engineered for minimal stretch—ideally under 15% at peak loads. This is what prevents anchor drag when the wind really kicks up, sometimes as high as 50 knots. The data doesn't lie: rope failures were a factor in 25% of anchoring incidents in US Coast Guard reports from 2015-2023, which just goes to show why sticking with rigorously tested products is so important.

Mastering Your Anchor Rope Connections

Even the toughest, most expensive boat anchor rope is worthless if your connections give out. When an anchoring system fails, it's almost always at the spot where the rope meets the chain or the chain meets the anchor. Getting these connections right isn't just a technical exercise—it's a core part of responsible boating that makes sure your gear actually works when you need it most.

Think about it: you wouldn't trust a cheap plastic buckle on a heavy-duty tow strap. It's the same logic here. Every single piece, from the shackle to the splice itself, has to be ready for the job. Building these bomb-proof connections is what transforms a simple length of rope into a reliable anchor rode you can trust when the weather turns.

The Non-Negotiable Thimble

At the end of your anchor line, where it hooks up to the chain, there's a huge amount of stress and friction. Without something to protect it, the constant sawing motion against a metal shackle would chew through the rope fibers in no time, creating a massive weak spot. This is exactly why a stainless steel thimble is absolutely essential.

A thimble is just a grooved metal loop that you splice directly into the eye at the rope's end. It acts like a tough, protective shield, taking the full brunt of the abrasion from the shackle. Heading out without a thimble is one of the most common—and dangerous—mistakes a boater can make.

Splicing a thimble into a 3-strand rope isn't just a handy trick—it’s a foundational skill for any dedicated boater. A properly executed splice maintains up to 95% of the rope's original breaking strength, while a knot can reduce it by as much as 50%.

Learning how to do this yourself means you can create and repair your own gear, knowing every connection is as strong as it can possibly be. It’s a rewarding process that connects you more deeply to your equipment and your boat's safety.

Choosing the Right Hardware

The hardware linking your system together is just as critical as the rope itself. You'll mainly be working with two types of shackles to connect your anchor chain to your rope or anchor.

- Bow Shackles: These have a more rounded, "O" shape that lets them handle loads from multiple directions. They’re perfect for attaching the anchor to the chain, since the anchor can shift and pull from different angles on the seabed.

- D-Shackles (or Dee Shackles): Shaped like the letter "D," these are built for loads that pull in a straight line. They make an excellent choice for connecting the thimble on your rope directly to the end link of your anchor chain.

When you're buying hardware, always go for high-quality, marine-grade stainless steel. Cheaper galvanized options will eventually rust and fail. For a truly reliable setup, consider pairing your rope with robust anchor chains and shackles specifically designed to survive the harsh marine environment.

Securing the Bitter End

The last, and often forgotten, connection is the bitter end—the end of the rope that stays on your boat. This end must always be tied off securely to a strong point inside your anchor locker, like a dedicated cleat or a sturdy eye bolt.

This attachment serves a vital purpose. It’s what stops you from accidentally losing your entire anchor rode overboard if the line slips while you're paying it out. And in a real emergency where you have to cut the line, knowing it's secured lets you do it quickly and safely without watching hundreds of feet of rope and your anchor disappear into the deep. It’s your system's last line of defense.

How to Properly Maintain and Inspect Your Anchor Rope

Your boat anchor rope lives a tough life. It’s constantly fighting a battle against corrosive saltwater, baking UV rays, and incredible strain. Think of it like any other critical piece of safety gear on your boat—it needs a little TLC to stay reliable.

A simple maintenance routine is all it takes to extend its life and, more importantly, keep you and your crew safe out on the water. This isn't just about looking good; it's about preserving the rope's strength. A neglected rope is a weak rope, and you don’t want to find that out when you need it most.

The Post-Trip Maintenance Routine

After every single trip, especially in saltwater, give your rope a good rinse with freshwater. This is non-negotiable. When salt water evaporates, it leaves behind tiny, sharp salt crystals that get deep into the rope’s fibers. Over time, they act like sandpaper, grinding away at the rope from the inside out and seriously weakening the line.

Once it's rinsed, coiling and storing it properly is the next crucial step. Don't just stuff it into a damp locker and forget about it.

- Coil Correctly: Always coil your rope in large, neat loops. This prevents the nasty kinks and tangles that put unnecessary stress on the fibers.

- Store for Ventilation: Tuck the coiled rope into an anchor locker that gets good airflow. Letting it dry completely is your best defense against mold and mildew.

- Avoid Direct Sunlight: When you're not using it, keep your rope covered or stowed away from direct sun to minimize damage from UV rays.

If you spot some stubborn mildew stains that have already set in, a targeted cleaner is your best friend. Our Better Boat Mildew Stain Remover is made to knock out those spots without damaging the rope itself. This kind of specific care is a cornerstone of our recommended boat maintenance checklist.

How to Conduct a Thorough Rope Inspection

Regular inspections are your early warning system for catching problems before they become emergencies. At the start and end of every season, make a point to lay the entire rope out on a clean dock or deck and go over it inch by inch.

Knowing what to look for is half the battle. You’re on the hunt for the tell-tale signs that a rope is losing its integrity and getting close to retirement.

A rope that feels stiff and brittle or looks faded and fuzzy has likely suffered significant sun damage. UV radiation breaks down synthetic fibers over time, reducing their strength and elasticity long before they show obvious signs of fraying.

Use this quick checklist to guide your inspection:

- Chafing: Look for any fuzzy, frayed, or worn spots. Pay special attention to the area around the thimble and any other place the rope makes frequent contact with your boat.

- Stiffness or Brittleness: A healthy nylon rope should feel supple and flexible. If it’s stiff, hard, or makes a crackling sound when you bend it, that’s a huge red flag.

- Discoloration: Major fading is a clear sign of UV damage. A little color loss is normal, but if it looks chalky or washed-out, the fibers are weakened.

- Cuts and Nicks: Put on a pair of gloves and run your hands along the entire length. You'll be able to feel any small cuts or nicks that could compromise its strength.

Trust your gut on this one. If your rope just looks or feels "off," it's time for a replacement. Your anchor is your brake pedal on the water; you need to be sure the line connected to it is always in peak condition.

Common Questions About Boat Anchor Ropes

Even after you've got a handle on materials, scope, and basic care, some specific questions always seem to pop up. Getting those nagging questions answered is the last step to feeling truly confident at the helm. We’ve rounded up some of the most common things we hear from fellow boaters to clear up any lingering confusion about your boat anchor rope.

Think of this as the final piece of the puzzle, giving you straightforward answers so you can make smart, safe choices out on the water.

How Often Should I Replace My Boat Anchor Rope?

Honestly, there’s no magic number or fixed schedule for replacing an anchor rope. Its lifespan really depends on how often you use it, the quality of the rope itself, and the kind of abuse it takes. A much better way to go about it is to get in the habit of doing regular, hands-on inspections. A good rule of thumb is to give your entire rope a thorough look-over at the beginning and end of every season.

When you're checking it out, keep an eye out for these deal-breakers:

- Significant Chafe: Look for fuzzy, frayed spots where the rope has been rubbing against something rough.

- Stiffness or Brittleness: A good nylon rope should feel pliable. If it's hard, stiff, or makes a crackling sound when you bend it, the fibers are shot.

- Discoloration: Major fading is a tell-tale sign of UV damage, which absolutely guts the rope's strength.

- Cuts or Nicks: Even a small gash can slash your rope's breaking strength in a big way.

When in doubt, throw it out. Seriously. Your anchor rope is one of the most critical pieces of safety gear you own. If you have any hesitation about its condition, the cost of a new line is nothing compared to the peace of mind you get from knowing you're secure. A quality nylon rope that's well-cared-for can last for years, but it’s never worth pushing your luck with a worn-out one.

Can I Connect Two Ropes to Make My Anchor Line Longer?

While you can technically join two ropes, it is a really bad idea for your main anchor rode. We strongly discourage it. That connection point, whether it’s a knot or even a splice, creates a weak link right where you don't want one. It's just asking for trouble. That knot can also snag on your bow roller or jam up your windlass, turning a simple anchor retrieval into a dangerous mess.

Just to put it in perspective, a knot like a double fisherman's bend can gut your rope's breaking strength by as much as 50%. A professional splice is way better, but nothing beats the reliability of a single, continuous piece of rope. Do yourself a favor and invest in one solid anchor line that’s long enough for the deepest water you plan to visit.

What Is the Difference Between an Anchor Rope and a Dock Line?

They might look alike, and they're often both made of nylon, but anchor ropes and dock lines have very different jobs. An anchor rope (or rode) is built for elasticity. It has to stretch and absorb the massive shock loads from wind and waves yanking on your boat. That stretch is what keeps your anchor from getting violently ripped out of the seabed.

Dock lines need some of that shock absorption too, but their main gig is dealing with constant, low-grade rubbing against a dock or piling. The real differences come down to their use and length.

- Anchor Rode: Needs to be super long—think 150-300 feet—to get the right scope and is designed for maximum stretch.

- Dock Lines: Are way shorter, sized specifically for tying up your boat nice and snug in a slip.

You can outfit your boat with specialized, high-quality dock lines built specifically to handle the unique wear and tear of being tied to a pier.

Why Do I Need Chain Between My Anchor and Rope?

Putting a length of chain between your anchor and your rope isn't just a suggestion; it's a universal best practice for a few huge reasons. This combination rode is simply leagues better than an all-rope setup.

First, the chain's weight does the heavy lifting. It physically holds the anchor's shank down, forcing the flukes to dig into the bottom at the correct horizontal angle. This is what gives you maximum holding power. Without that weight, the rope pulls the anchor upwards, and it won't set properly.

Second, chain is incredibly tough and abrasion-resistant. It acts as a sacrificial leader, taking the scrapes and abuse from rocks, coral, or whatever else is on the seafloor. This protects your more delicate nylon rope from getting shredded and dramatically extends its life.

Finally, the sheer weight of the chain creates a "catenary effect"—a natural curve that acts as a built-in shock absorber. This works hand-in-hand with the nylon rope's stretch to give you a much smoother, more secure ride when things get choppy. Adding a proper length of robust anchor chain to your system is one of the smartest and safest upgrades you can make.

At Better Boat, we know that having reliable gear is the key to enjoying your time on the water. From durable anchor ropes and chains to premium cleaning supplies, we offer everything you need to maintain your vessel with confidence. Explore our full range of tried-and-tested boating products today.

Find the perfect gear for your boat at https://www.betterboat.com.