How to Paint a Fiberglass Boat for a Showroom Finish

Painting a fiberglass boat isn't just a weekend project; it's a commitment to bringing back that showroom shine and protecting your investment. Getting it right comes down to three things: meticulous prep work, picking the right marine paint, and applying it with care.

Choosing the Right Marine Paint System for Your Boat

The secret to a jaw-dropping finish that lasts season after season starts right here, with the cans you choose. This decision is about more than just the color—it's about chemistry. The type of paint you pick will directly impact your boat's durability, how it looks gliding through the water, and how much elbow grease you'll need to put in.

Honestly, selecting the right coating system is the most critical decision you'll make in this entire process. It sets the stage for everything else, from your budget and timeline to that final, satisfying look.

Understanding Marine Paint Types

When you walk down the aisle at a marine supply store, you'll see three main contenders for finishing a fiberglass boat: single-part marine enamels, two-part polyurethane systems, and the original champ, gelcoat. Each one has its own personality, and they’re built for different goals and skill levels.

- Single-Part Marine Enamels: Think of these as the workhorses of the DIY world. They're affordable, forgiving, and incredibly user-friendly. If you're tackling your first paint job or just need a quick refresh on a smaller boat, applying this stuff with a simple brush and roller is a fantastic option.

- Two-Part Polyurethanes: If you’re chasing that professional, mirror-like gloss that looks wet even when it’s dry, this is your stuff. These systems involve mixing a base paint with a hardener, creating a finish that’s ridiculously tough and resistant to chemicals, fuel, and abuse. They’re pricier and more demanding to apply, but the durability is second to none.

- Gelcoat: This isn't technically a paint, but a polyester resin. It’s what most fiberglass boats wear straight from the factory. Gelcoat is exceptionally durable and can be polished to a brilliant shine. Applying it is a whole different ballgame than painting—often requiring spray equipment—but it offers the most authentic and robust protection for your hull.

A Quick-Glance Guide to Marine Paints

Making the right choice can feel overwhelming, so I've put together a quick comparison table. This should help you weigh the pros and cons based on what matters most to you: durability, budget, and the time you're willing to invest.

Marine Paint Comparison for Fiberglass Boats

| Paint Type | Best For | Durability | Ease of Use (DIY) | Estimated Cost |

|---|---|---|---|---|

| Marine Enamel | DIY projects, budget-conscious owners, topside touch-ups | Good (3-5 years) | Very Easy | $ (Low) |

| 2-Part Polyurethane | A professional, high-gloss finish; high-wear areas | Excellent (10+ years) | Difficult | $$$ (High) |

| Gelcoat | Restoring the original factory finish; below-waterline use | Exceptional (15+ years) | Very Difficult | $$ (Medium-High) |

Each of these options can deliver a great result, but only if you match the paint to the project and your own skill level. A perfectly applied enamel will always look better than a poorly applied two-part polyurethane.

Gelcoat and Its Growing Importance

Gelcoat is more than just a shiny surface; it's the primary protective layer for the fiberglass laminate underneath. Think of it as the tough, colored skin that shields your hull from everything the water and sun can throw at it—UV rays, saltwater, and the occasional bump against the dock.

The global marine gelcoat market hit $4.2 billion in 2022 and is expected to climb to $7.5 billion by 2032, which just goes to show how vital it is in boat building and maintenance. A proper gelcoat application can easily add 5-10 years to your hull's life and save you a ton on future repainting costs.

Key Takeaway: Here's the big difference: paint forms a film over the surface, while gelcoat becomes an integral part of the fiberglass structure itself. This is what makes it so incredibly durable, but also what makes it trickier to repair seamlessly compared to paint.

The Critical Role of Primers

I don't care which topcoat you choose—if you skip the primer, you're setting yourself up for failure. It’s that simple. Primer is the glue that holds your entire paint job together, the essential bonding agent that makes your expensive topcoat stick to the hull.

A quality marine primer, especially a two-part epoxy primer, does several jobs at once.

First, it bites into the prepared fiberglass, creating a rock-solid mechanical and chemical bond for the new paint. This is non-negotiable when you're painting over old, sanded gelcoat.

It also acts as a barrier coat, sealing the porous fiberglass to prevent moisture from getting in and causing blisters later on. Finally, a good primer will fill in tiny surface scratches and imperfections left after sanding, giving you that perfectly smooth canvas your topcoat deserves. If you want to dive deeper into protective layers, our guide on clear coating a boat offers some great insights into building a bulletproof finish.

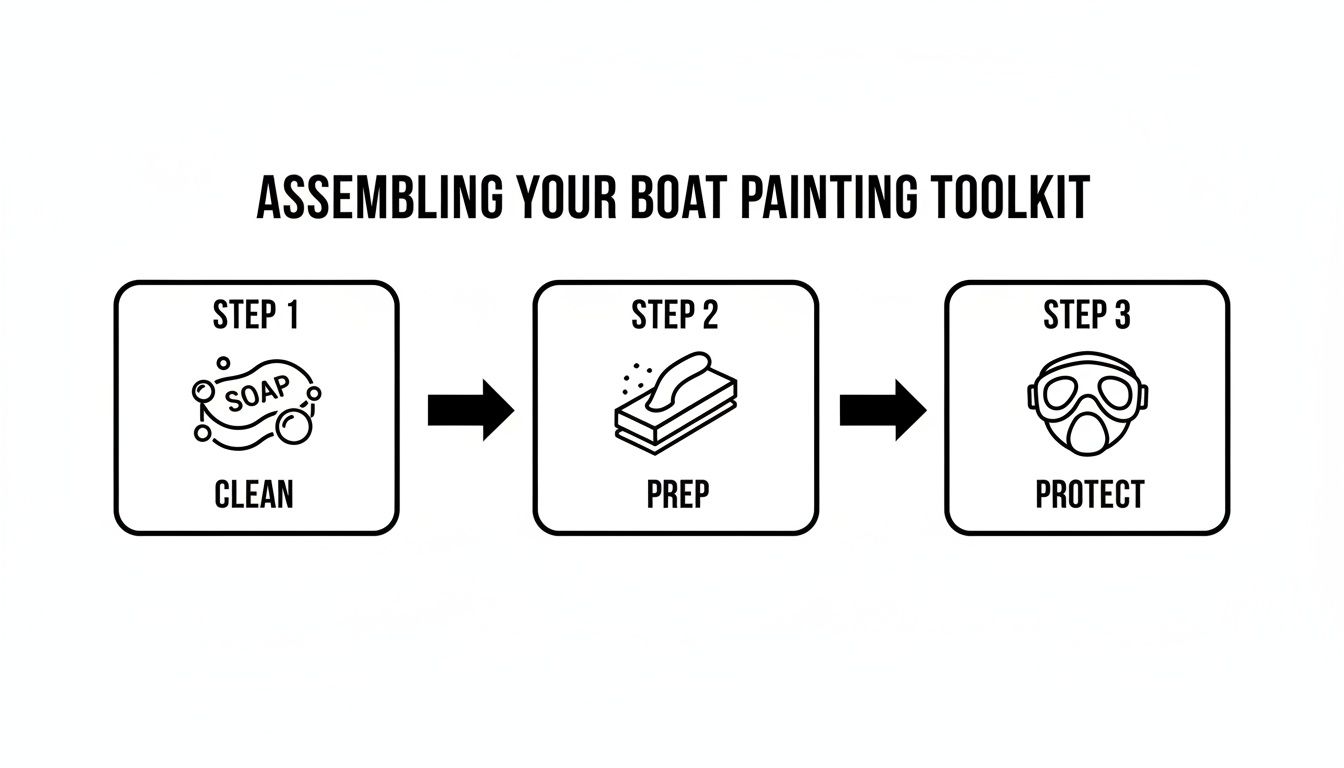

Assembling Your Boat Painting Toolkit

Any seasoned boater will tell you that the right gear can turn a monster of a project into something you can actually tackle—and maybe even enjoy. When you’re learning how to paint a fiberglass boat, a well-stocked toolkit is your best friend. It’s what ensures every stage, from the first scrub-down to the final gleaming coat, goes off without a hitch.

This isn’t just about having a tool for the job; it’s about having the right one. Think about it: you wouldn't grab a kitchen knife to carve wood. In the same way, your household cleaning supplies and the wrench set from the garage just aren't built for the harsh marine environment. Investing in the proper equipment upfront is the surest way to sidestep frustration and costly do-overs later on.

Core Cleaning and Preparation Tools

Before a single drop of paint touches your hull, that surface has to be surgically clean. This is way more involved than a quick rinse. You need tools that can power through years of salt, grime, and chalky oxidation without chewing up the fiberglass underneath.

Your first step is a high-quality soap formulated specifically for boats. Our All-Purpose Boat Soap is designed to lift that stubborn gunk and environmental fallout without stripping away any existing wax—making it perfect for that initial deep clean. You’ll want to pair it with a good, ergonomic brush set that can get into all the different curves of your boat. The Better Boat Scrubber Brush Set comes with different heads to handle everything from wide-open surfaces to the tight spots around cleats and rails.

Beyond the initial wash, your prep arsenal needs a few more key players:

- Sanders: A dual-action (DA) random orbital sander is an absolute game-changer for scuffing up large areas efficiently and, more importantly, evenly. Keep a few sanding blocks and a variety of sandpaper grits on hand (usually from 80-grit for heavy stripping to 220-grit for the final prep) for detail work.

- Scrapers: It's smart to have both metal and plastic scrapers. They're indispensable for peeling off old registration stickers, chipping away stubborn barnacles, or getting under failing bottom paint.

- Solvent Wipes and Dewaxers: This is a big one. You need specific solvents to wipe the surface down before sanding and again before priming. This step removes invisible paint-killers like wax, oil, and silicone that will ruin your finish. Make sure you use lint-free rags here to avoid contaminating the surface.

Application Essentials for a Pro Finish

Once the prep work is done, your mission shifts to laying down a smooth, even coat of paint. The tools you pick here have a direct line to the quality of your final finish. Whether you roll, brush, or spray, don't cut corners on quality.

For the "roll and tip" method—a popular technique that gives you a finish that’s darn close to a spray job—you need specific applicators. High-density, closed-cell foam rollers are non-negotiable; they won’t leave behind the fuzzy texture you’d get from a regular roller. You immediately follow the roller with a high-quality badger hair "tipping" brush to gently knock down any tiny bubbles and create that flawless, wet-glossy look.

Pro Tip: Don’t cheap out on painter's tape. A premium tape, like the blue or green lines from 3M, will give you razor-sharp edges and won't leave a sticky mess. This is absolutely critical for getting a crisp, professional boot stripe.

Here are a few other must-haves for application:

- Mixing Containers: Grab some clear, graduated mixing buckets. They're essential, especially if you're using two-part paints where the mix ratio has to be perfect.

- Stir Sticks: You can never have too many. Use them for mixing everything from paint and primer to epoxy fillers.

- Tack Cloths: These are slightly sticky cloths you’ll use to give the surface one last wipe-down right before the primer or paint goes on. They pick up any lingering dust particles that could mar your finish.

Non-Negotiable Safety Equipment

Let's be clear: working with marine paints, solvents, and sanding dust involves serious health risks. Your personal protective equipment (PPE) is the single most important part of your toolkit. It is 100% non-negotiable. The fumes from two-part polyurethane paints, for example, contain isocyanates, which are incredibly toxic if you breathe them in.

Your essential safety kit must include:

- Respirator: A half-mask or full-face respirator fitted with organic vapor cartridges is mandatory. A simple paper dust mask won't do a thing against chemical vapors.

- Eye Protection: You need chemical splash goggles or, at a minimum, safety glasses to shield your eyes from splashes and airborne dust.

- Gloves: Chemical-resistant nitrile or neoprene gloves are a must to keep aggressive solvents and paints off your skin.

- Protective Clothing: A disposable coverall with a hood is a smart move. It keeps paint, dust, and chemicals off your skin and clothes.

Putting together a complete toolkit is a foundational step for any successful boat project. For a more detailed look at the gear every boat owner should have in their dock box, check out our complete guide to must-have boat tools.

Getting the Surface Ready for Paint

Talk to any old hand at the marina, and they'll all tell you the same thing: a truly professional paint job is 80% preparation. This is the hard work, the part that happens long before a can of paint even gets opened. Get this stage right, and you're setting yourself up for a finish that will last for years.

It all kicks off with a serious, deep clean. Your boat's hull has seen it all—salt spray, algae, old wax, you name it. Every bit of that grime is an enemy to new paint, preventing it from getting a solid grip on the surface.

Start With a Spotless Surface

Your first mission is to get rid of every last trace of that surface contamination. This isn't a job for your dish soap from home; you need something formulated to tackle marine-grade buildup without harming the fiberglass. A good, pH-neutral boat soap is your first tool of choice. Mix it up and give the entire boat a good, hard scrub from the waterline up.

Don't forget to get into all the nooks and crannies around your hardware and fittings, as that's where dirt loves to collect. Once you're done washing, rinse everything down with fresh water and let the hull dry completely. For a deeper dive into this initial wash-down, check out our guide on how to clean a fiberglass boat.

The Make-or-Break De-Waxing Step

Here's a step a lot of first-timers miss, and it’s a critical one: de-waxing. Even after a thorough scrubbing, there's almost always an invisible film of old wax or silicone polish left behind. Paint will not stick to wax. Period. Trying to paint over it is just asking for peeling and blistering down the road.

To get it done right, grab a solvent-based wax remover and two clean, lint-free rags. Working in small sections, wipe the solvent on with the first rag, and immediately wipe it off with the second clean rag. This on-and-off technique is key—if you let the solvent flash off and evaporate, it just leaves the dissolved wax right back where it started.

Pro Tip: Think of it this way: Rag #1 dissolves and lifts the wax. Rag #2 carries it away for good. Using the same rag for both steps just moves the mess around.

This whole prep process follows a simple, logical flow. You clean, you prep, and you protect yourself.

Each step builds on the last, creating the perfect foundation for your new paint.

Fixing Dings, Scratches, and Gouges

Once the hull is clean and stripped of wax, every little imperfection will pop out. Now’s your chance to make them disappear. If you ignore them, a fresh coat of high-gloss paint will only make them more obvious.

For light surface scratches, a good sanding might be all you need. For anything deeper, you'll want to break out a marine-grade two-part epoxy filler. Mix it up exactly as the directions say and use a flexible putty knife to press it firmly into the damaged spot. Overfill it just a little bit, as it will shrink slightly as it cures and you'll be sanding it down.

Let the filler cure completely. Don't rush this part; it can take several hours. Once it's rock-hard, you can sand it perfectly smooth and flush with the rest of the hull. This is how you get that flawless, "fair" surface that looks so good under new paint.

The Right Way to Sand

Sanding isn't just about smoothing out repairs; it's about creating a "tooth" for the primer to bite into. It's a dusty job, but it’s absolutely non-negotiable for good adhesion. Choosing the right sandpaper is half the battle.

- For heavy lifting (80-120 grit): Use this coarser grit for feathering the edges of your epoxy repairs or tackling any stubborn patches of old paint that just won't quit.

- For final prep (220-320 grit): Once the repairs are faired, go over the entire hull with a finer grit. This scuffs the gelcoat just enough to create a strong mechanical bond for the primer without leaving deep scratches behind.

For the big, flat areas of the hull, a dual-action (DA) random orbital sander will save you a ton of time and effort. But you'll still want to keep some sanding blocks on hand for getting into those tight curves and corners. This principle of proper sanding isn't unique to boats; it's the foundation of any quality paint job, and you can even learn general tips from pros who know how to prep walls for painting like a pro.

After all that sanding, you're almost there. Give the boat one final wipe-down with a solvent to pick up any oils, followed by a tack cloth to grab every last speck of dust. Now—and only now—is your fiberglass boat truly ready for its first coat of primer.

Applying Primer and Paint For a Flawless Finish

Alright, this is where all that tedious prep work finally pays off. It's time to lay down a stunning finish that will last for years.

Whether you're brushing, spraying, or doing the classic "roll and tip," each technique has its own rhythm and reward. Spraying gives you that factory-smooth finish, but don't count out a good roller and tipping brush—in the right hands, it can look just as good without the expense of a spray rig.

Before you even think about cracking open a can of paint, give the hull one last check. It needs to be completely degreased, dust-free, and bone dry for the paint to stick properly.

- Brushing: Perfect for cutting in around hardware and tackling tight spots where you need total control.

- Spraying: The fastest way to get the sleekest finish, especially on large surfaces, assuming you have the equipment and know-how.

- Roll and Tip: The go-to DIY method. It’s a fantastic balance of speed and a near-professional finish using a foam roller and a high-quality brush.

Choosing Your Application Method

Your choice really comes down to the size of the job, your budget, and how much time you want to spend on setup and cleanup.

For small jobs, touch-ups, or intricate areas, nothing beats a good-quality brush. For larger, flatter areas, you'll want to move to a foam roller or a spray system. Just remember that each one has different rules for thinning and application.

The roll and tip method is a fan favorite for a reason. You'll need a dense foam roller (a 6- to 9-inch one works great) and a quality synthetic bristle brush for the "tipping" part.

Here’s the trick: work in small, manageable sections, about 4x4 feet at a time. This lets you maintain a "wet edge," which is the secret to avoiding ugly lap marks where your sections overlap.

A few pointers for the roll and tip method:

- Get a moderate amount of paint on the roller, but not so much that it's dripping everywhere.

- Roll the paint on in one direction, then lightly go back over it in the opposite direction (cross-rolling) to even it out.

- Immediately—within five minutes—use the dry brush to gently "tip" the surface, smoothing out the roller texture into a glass-like finish.

Mixing Two-Part Paints Correctly

If you're using a two-part epoxy or polyurethane, this step is critical. Get the mix ratio wrong, and the paint will never cure properly. It's that simple.

Always follow the manufacturer's instructions for induction time. That's the short waiting period right after mixing that allows the chemicals to start bonding before you apply the paint. You also need to watch the "pot life"—the amount of time you have to use the paint before it starts to thicken up. At 70°F, this can be anywhere from 30 minutes to an hour.

Even the most experienced painters run into issues. Here's a quick guide to some common problems and how to solve them.

Fiberglass Painting Troubleshooting Guide

| Problem (e.g., Orange Peel, Runs/Sags, Fish Eyes) | Probable Cause | How to Fix It |

|---|---|---|

| Orange Peel | Incorrect spray pressure or roller technique. Paint might be too thick. | Adjust your spray gun's fluid flow, or use less pressure when rolling. Tip the surface immediately after rolling. |

| Runs/Sags | Applying too much paint at once or not waiting long enough between coats. | Let it dry completely, sand the drips smooth, and then apply several thinner coats. |

| Fish Eyes | Surface contamination. Usually oil, wax, or silicone residue. | This is a tough one. You'll need to sand the area down, reclean thoroughly with a good solvent, and ensure zero residue before repainting. |

It's always a good idea to mix a small test batch and apply it to a piece of scrap material first. This lets you double-check your flow and set times before you commit to the hull. And when you stir, do it gently! Whipping it up like you're making a milkshake will introduce air bubbles that will show up in your final coat.

Applying Multiple Thin Coats

The biggest rookie mistake is trying to get full coverage in one thick coat. It’s a shortcut that leads directly to runs, sags, and a paint job that fails way too soon.

The key is to build up the finish with multiple thin coats. Aim for 3 to 5 coats, letting each one "flash off" until it's just tacky to the touch before applying the next. This method builds incredible depth and durability while allowing solvents to escape properly.

With the leisure boat marine coatings market projected to grow from $1.62 billion to $2.43 billion by 2035, it's clear that protecting our investments is a top priority. A quality paint job is your best defense against osmosis, which can cause blistering on 15–20% of fiberglass hulls within just five years.

Pro Tip: After a thorough degreasing, laying down 2–3 thin coats of an epoxy primer, like our Two-Part Epoxy Primer, can boost final paint adhesion by as much as 50%.

You can check out the full market analysis from Future Market Insights to see the trends for yourself.

Working With Weather Conditions

The weather is your silent partner—or your worst enemy—on paint day. High humidity, scorching sun, or an unexpected rain shower can ruin hours of hard work.

Morning dew can kill adhesion, and direct sun can make the paint dry too fast, trapping bubbles and creating a rough finish.

Plan your paint day around the forecast:

- Temperature should be between 60°F and 85°F.

- Relative humidity needs to be below 65%.

- You want at least 24 hours with no rain in the forecast.

- Pick a day with low wind to keep dust and debris out of your wet paint.

If you can, try to paint in a shaded area or during the cooler parts of the day. This gives the paint a chance to flow and level out properly before it starts to set up.

Masking And Cleanup

A sharp paint line is the signature of a professional job. Good masking is what gets you there. Take your time taping off hardware, windows, and the waterline.

Once you’ve applied your final coat, don't wait too long to pull the tape. If you let the paint fully cure, you risk peeling off chunks of your hard work along with the tape. The sweet spot is usually within 30 minutes of your last pass.

Pro Tip: For the cleanest possible lines, pull the tape off slowly, pulling it back on itself at a 45-degree angle.

Protecting Your New Paint Job for the Long Haul

That last brush stroke might feel like the finish line, but it’s really the start of the most critical phase of your boat painting project. Your work isn't over just because the paint is dry to the touch. This stage is all about patience and protection, ensuring that incredible shine lasts for many seasons to come.

Getting this part right separates a good DIY job from a great one. It’s the difference between a finish that looks good for a few months and one that’s still turning heads at the dock years down the road.

Understanding the Curing Process

It's absolutely vital to know the difference between paint that's 'touch dry' and one that has achieved a 'full cure.' Marine paints, especially the two-part polyurethanes, go through a chemical process that hardens them from the inside out, and it takes time.

- Touch Dry: This can happen in just a few hours. The surface feels dry, but the paint underneath is still soft, gooey, and vulnerable. At this point, it's easily damaged by moisture, a stray insect, or an accidental bump.

- Full Cure: This is the point where the paint has reached its maximum hardness and chemical resistance. This process can take anywhere from 7 to 14 days, sometimes longer, depending on the paint, temperature, and humidity.

Launching your boat before the paint is fully cured is one of the biggest—and most heartbreaking—mistakes you can make. The pressure from trailer rollers, fenders, or even just sitting in the water can leave permanent marks in the soft finish, undoing all your hard work in an instant.

Crucial Takeaway: Always, always follow the manufacturer's recommended full cure time on the technical data sheet. Patience here isn't just a virtue; it's a non-negotiable requirement for a durable, long-lasting finish.

Achieving That Ultimate Gloss

Once your new paint has completely cured, you can take its shine to the next level. If you're chasing that flawless, mirror-like surface, wet sanding and polishing is the final step to perfection.

This involves lightly sanding the surface with ultra-fine grit sandpaper—starting around 1,500-grit and moving up to 3,000-grit—using plenty of water as a lubricant. This delicate process shaves off any minor surface imperfections, like tiny dust nibs or a slight "orange peel" texture.

After sanding, a multi-stage polishing process with a machine polisher and progressively finer compounds will bring out a deep, brilliant gloss that's simply impossible to achieve otherwise. It’s a lot of work, but the spectacular results speak for themselves.

Protecting Your Investment

With your paint cured and polished to perfection, the final job is to protect it. A high-quality protective layer is your boat's first line of defense against everything trying to dull its new finish—harsh UV rays, saltwater, bird droppings, and oxidation.

Applying a protective coating is the single most effective maintenance step you can take. A quality carnauba-based wax like our Marine Boat Wax provides excellent UV protection and a deep, rich shine that really makes the color pop.

For those looking for even longer-lasting protection with less frequent application, a synthetic option like our Hybrid Ceramic Sealant offers superior durability and incredible hydrophobic properties. For a detailed guide on how it's done, you can learn more about how to wax your boat for maximum protection.

If you’re curious about the high-end options, it can be helpful to compare ceramic coating and PPF for paint protection to see what's happening in the automotive world, as many of these technologies are making their way into the marine industry. Remember, regular washing and waxing isn't just about looks; it's preventative maintenance that shields your investment and keeps that 'just painted' look season after season.

Common Questions About Painting a Fiberglass Boat

Even the most detailed plan can leave you with questions, especially when you're figuring out how to paint a fiberglass boat for the first time. It can feel like a massive job, but getting a few clear answers can make all the difference. We've rounded up some of the most common questions we hear from boat owners to help you tackle this project with confidence.

Can I Just Paint Directly Over the Old Gelcoat?

Absolutely not, and this is probably the single biggest mistake you can make. Over time, gelcoat gets oxidized and chalky, which is a terrible surface for paint to grab onto. Think of it like trying to put a piece of tape on a dusty, greasy countertop—it’s just not going to stick.

You have to put in the prep work. That means a thorough cleaning, de-waxing, and sanding the entire surface to give the new paint something to mechanically bond to. Once it's sanded, a good two-part epoxy primer is non-negotiable. It’s what ensures your new paint job adheres properly and doesn’t start peeling or blistering a season later.

How Much Will It Cost to Paint My Boat Myself?

If you’re doing it yourself, a 20-25 foot boat will likely run you somewhere between $500 and $2,000. The final number really comes down to the paint you choose. Premium two-part polyurethane systems will push you toward the higher end of that range, while single-part marine enamels are a more wallet-friendly option.

That estimate should cover all your supplies:

- Paint and primer

- The necessary solvents and cleaners

- Sandpaper, rollers, and brushes

- And of course, essential safety gear like a good respirator and gloves

While it's not cheap, it’s a tiny fraction of the $5,000 to $15,000+ a professional boatyard could charge for the same job.

What Are the Perfect Weather Conditions for Painting?

You're looking for a Goldilocks day. Try to find a window with temperatures between 60°F and 85°F (15°C to 29°C) and relative humidity below 65%. Whatever you do, avoid painting in direct, scorching sunlight. It makes the paint dry way too fast, which can trap solvent bubbles under the surface and leave you with a blotchy, uneven finish.

High humidity is the arch-nemesis of two-part paints. Moisture in the air can react with the curing agents and leave the finish looking cloudy or dull—a frustrating problem known as "blushing." Always, always check the paint's technical data sheet for what the manufacturer recommends.

How Long Until My Newly Painted Boat Can Go in the Water?

This is where patience is a virtue. The paint might feel dry to the touch in just a few hours, but it's a long way from being fully cured and hardened. Most marine paints need a bare minimum of 7 to 14 days in good conditions before the boat is ready to launch.

Splashing the boat too soon can wreck all your hard work. A soft paint finish can be permanently damaged, leaving impressions from trailer bunks or fenders. Always stick to the full cure time the paint manufacturer lists on the can—it’s the only way to protect that beautiful new finish.

Getting a professional-looking finish on your boat is an incredibly rewarding project, and having the right tools is half the battle. For everything you need to clean, prep, and protect your vessel, you can count on Better Boat. Check out our complete line of premium boat care products at betterboat.com and get your boat looking its absolute best.