Your Essential Guide to Thru Hull Fittings

Thru-hull fittings are the pieces of hardware that create a waterproof seal for any opening in a boat's hull. Think engine cooling, drains, and sanitation systems—anything that needs to move water in or out. They are a critical safety component, acting as the gatekeepers between the inside of your boat and the big blue sea.

The Unsung Guardians of Your Boat's Hull

Picture your boat's hull as a perfect, seamless barrier keeping the water out. Now, think about all the necessary holes you need for things like engines, drains, and livewells. The small pieces of hardware lining these holes—thru-hull fittings—are the unsung guardians that keep your vessel afloat. They turn a potential weakness into a controlled and secure connection.

You can think of them as the vital arteries and veins of your boat. They let essential functions happen below the waterline, from pulling in raw water to cool the engine to pumping waste out of the bilge. Without them, a modern boat just couldn't work.

Why They Are So Important

This small, often-overlooked piece of hardware is arguably one of the most important safety components on any vessel. A single failed thru-hull fitting can let hundreds of gallons of water pour into your boat in minutes, creating a catastrophic emergency when you're far from shore. The integrity of your entire vessel often rests on the strength and reliability of these humble fittings.

A well-maintained thru-hull is a silent protector, but a neglected one is a ticking clock. Understanding their function is the first step toward ensuring your boat remains safe and seaworthy.

A failure isn't always a dramatic geyser of water. It can start as a slow, persistent drip that goes unnoticed, leading to hidden water damage, rot, and delamination within the hull structure. This is why knowing how to inspect, maintain, and correctly install them isn't just good practice—it's essential seamanship. For more on keeping your hull sound, our guide on repairing a boat hull offers some valuable insights into maintaining this crucial barrier.

The Foundation of Boating Safety

Ultimately, every connection point below the waterline is a calculated risk. By choosing the right materials, ensuring proper installation, and performing regular maintenance, you transform these potential weak points into strong, reliable systems. The stakes are high, which is exactly why it’s so critical to understand how to select, install, and care for your thru-hull fittings correctly.

Choosing the Right Material for Your Thru Hull

Picking the right material for your thru-hull fittings is one of the most critical decisions you'll make for your boat’s safety. This isn't just about what looks best or what's on sale; it's a serious choice based on where you boat, the type of vessel you have, and your budget. Get it wrong, and you could be looking at rapid corrosion and a catastrophic failure below the waterline.

Today, you've got three main players on the field: classic bronze, sleek 316 stainless steel, and modern composite plastics. Each one strikes a different balance between strength, corrosion resistance, and price. Let's break them down so you can pick the right guardian for your hull.

Bronze: The Time-Tested Champion

For generations of saltwater boaters, bronze has been the undisputed king of thru-hulls, and for good reason. It’s incredibly resistant to corrosion, especially galvanic corrosion—that destructive electrical process that eats away at lesser metals in saltwater.

Bronze fittings are famous for their longevity, often lasting for decades with just basic care. While they might be the priciest option upfront, their sheer durability makes them a smart investment over the life of your boat. Their only real tell-tale sign of aging is dezincification, which happens when zinc leaches out of the alloy, leaving a weak, pinkish copper structure behind. If you see pink, it's time for a replacement.

316 Stainless Steel: Sleek and Strong

Stainless steel thru-hulls, specifically those made from 316-grade alloy, bring superior strength and a sharp, modern look to the table. You'll often see them on high-performance and luxury boats where aesthetics and raw mechanical toughness are top priorities.

But stainless steel has an Achilles' heel: crevice corrosion. In places starved of oxygen, like underneath a glob of sealant or in stagnant water, the protective layer on the steel can break down. This leads to nasty, hidden pitting that can compromise the fitting from the inside out. For this reason, perfect installation and regular, eagle-eyed inspections are non-negotiable.

Composite Plastics: The Modern Contender

Forget the brittle plastics of the past. Today's composite thru-hull fittings are made from high-strength, glass-reinforced polymers, and they offer some serious advantages.

Their biggest selling point? They are 100% immune to both galvanic and crevice corrosion, which makes them a fantastic choice for any type of water, fresh or salt. They're also lightweight and usually the most budget-friendly option. Composites have come a long way, with top brands earning certifications for use below the waterline from major marine authorities.

The trade-offs? They can be susceptible to UV damage if they're exposed to direct sunlight, and they can become brittle in extreme cold. It's also vital to use a compatible sealant, as some aggressive chemicals can weaken the plastic over time. Our Marine Sealant is formulated to be compatible with a wide range of materials, ensuring a strong bond without damaging your fittings. If you want to dive deeper into other sealants, check out our guide on 3M 4200 vs 5200.

No matter the material, the integrity of a thru-hull fitting is only as good as its installation. The right sealant, a proper backing block, and careful tightening are just as crucial as the material itself.

To help you decide, here's a quick side-by-side comparison of the top materials.

Comparing Thru Hull Fitting Materials

This table compares the key characteristics of bronze, 316 stainless steel, and composite plastic thru-hull fittings to help you choose the best option for your boat.

| Material | Best For | Corrosion Resistance | Strength | Average Cost |

|---|---|---|---|---|

| Bronze | Saltwater, long-term cruising | Excellent | Very Good | High |

| 316 Stainless Steel | High-performance boats, aesthetics | Good (with risks) | Excellent | High |

| Composite Plastic | Freshwater, trailer boats, budget-conscious owners | Excellent (immune) | Good | Low |

Ultimately, the best material for your thru-hulls comes down to your specific needs.

Making the Right Choice

So, how do you pull the trigger on the right material? It really boils down to how and where you use your boat.

- For the bluewater cruiser in saltwater: Bronze is still the gold standard. Its proven track record against galvanic corrosion delivers priceless peace of mind when you're far from shore.

- For the freshwater or trailer boater: High-quality composites are an excellent, corrosion-proof, and wallet-friendly choice.

- For performance boats needing maximum strength: 316 stainless steel is a solid option, but only if you're committed to meticulous installation and routine inspections for crevice corrosion.

By balancing cost, your boating environment, and how much maintenance you're willing to do, you'll land on the perfect material to keep your boat safe and dry.

How to Size and Measure Thru Hulls Like a Pro

When it comes to thru-hulls, "close enough" is a recipe for disaster. This is one boat project where you absolutely have to get the sizing right. An improperly sized fitting isn't just a minor issue—it's a guaranteed leak waiting to happen, creating a risk that could range from a wet bilge to a catastrophic failure below the waterline.

Getting this right isn’t about guesswork. It’s about nailing three critical measurements. These steps ensure every part of the system, from the hole in your hull to the hose you clamp on, forms a perfect, watertight seal. Let’s walk through exactly how to do it.

Measuring the Hose Inner Diameter

First up is the easy one: the inner diameter (ID) of the hose you’re connecting. Thru-hull fittings are named for the hose they fit. Simple as that. A 1" thru-hull is made for a hose with a 1" inner diameter.

To figure this out, you can:

- Check the existing hose: Most marine hose has its size printed right on the side.

- Measure the old fitting: If you're swapping one out, just measure the outside diameter of the barbed part where the hose slipped on.

- Measure the hose directly: For unmarked hoses, a caliper or a precise ruler will give you the inside opening measurement.

Don't eyeball this. A hose that’s too big or too small for the fitting creates a weak spot that even the beefiest hose clamp can't truly secure.

Understanding Thread Types

This is where a lot of boat owners get tripped up, and it's a dangerous mistake to make. Not all threads are created equal, and mixing them up is a classic blunder. On a boat, you're almost always dealing with two types.

Mismatched threads might feel like they're tightening down, but they will never form a strong, permanent seal. It's a false sense of security that leads to slow leaks and eventual failure.

It's critical to know what you're working with:

- National Pipe Straight (NPS): This is the gold standard for marine thru-hulls. The threads are parallel, meaning the seal comes from the flange and nut compressing against the hull (with sealant and a backing block), not from the threads themselves.

- National Pipe Tapered (NPT): You’ll find these all over household plumbing. The threads are tapered to jam together and create a seal. This is a huge no-no for most thru-hull setups, as cranking down on them can easily crack the fitting or even damage your hull.

Your seacock and your thru-hull must have matching threads. Never, ever mix NPS and NPT fittings. It creates an inherently weak connection just waiting to fail.

Calculating the Required Length

The final piece of the puzzle is getting the length right. This depends entirely on the thickness of your hull and any backing block you’re using. The threaded part of the thru-hull needs to be long enough to pass all the way through the hull and backing block, with plenty of thread left over to fully engage the seacock or locknut.

Follow these steps for a perfect measurement:

- Measure Hull Thickness: Grab a caliper or a hook-ended tape measure to find out how thick your hull is right at the installation point.

- Add Backing Block Thickness: Measure the thickness of your backing block.

- Add Seacock/Nut Thickness: Figure out how much thread the seacock or nut needs to grab onto. A good rule of thumb is to add at least another 1/2 inch to make sure you get full, solid thread engagement.

Add those three numbers together, and you've got your minimum required length. When in doubt, it’s always better to get a fitting that’s a little too long—you can always trim it down. One that's too short won't let the seacock seat properly, and that’s a major safety hazard.

A Step-by-Step Guide to Thru Hull Installation

Replacing or installing a thru-hull fitting is one of those boat jobs where getting it right isn't just a goal—it's absolutely critical for the safety of your vessel. While it might look intimidating, breaking the process down into clear, manageable steps makes it a job any confident DIYer can tackle.

This guide will walk you through the whole process, from wrestling with the old hardware to getting that permanent, waterproof seal that lets you sleep soundly at night.

First things first, let's get the biggest rule out of the way: the boat must be out of the water. Seriously. Trying to do this job while afloat is a recipe for disaster and is just asking for a catastrophic flood. Once your boat is safely on the hard, you can give this task the full attention it deserves.

Preparing for a Perfect Seal

The success of your new thru-hull hinges entirely on the prep work. This is no time to cut corners. A clean, perfectly prepped surface is the only way to get a leak-proof seal that will hold up for years to come.

Getting started means getting the old fitting out. Honestly, this can be the toughest part of the entire job, especially if the last person used some super-aggressive adhesive. You'll probably need a dedicated thru-hull wrench or a hefty pipe wrench to get enough muscle behind it. Once the old fitting is finally out, the real prep work begins.

Your next mission is to scrape, scrub, and clean every last bit of old sealant from the hull, both inside and out. A good scraper, some acetone, and a healthy dose of patience are your best friends here. You want to get all the way down to the bare gelcoat or fiberglass so the new sealant has a perfectly clean surface to grab onto. Any gunk left behind will absolutely compromise the new seal.

Installing the Backing Block and Fitting

With a spotless surface ready to go, it’s time to think about structural support. Any thru-hull fitting below the waterline needs a backing block on the inside of the hull. This isn't an optional step; the backing block is what spreads the load from the fitting and the seacock across a wider area, preventing dangerous stress cracks and potential hull failure.

Follow these steps for a rock-solid installation:

- Dry Fit Everything First: Before you even pop the cap on a tube of sealant, do a complete dry run. Slide the new thru-hull into the hole, place the backing block over it inside the boat, and thread on your seacock or locknut. Make sure you've got enough thread length and that everything sits perfectly flush.

- Prepare the Backing Block: Use a thickened epoxy to "bed" the backing block to the interior of the hull. This creates a solid, gap-free foundation and essentially glues the block permanently in place. Let the epoxy cure completely before you move on to the next step.

- Apply Sealant Liberally: This is where the magic happens. Grab a high-quality, flexible marine-grade sealant. A product like our Better Boat Marine Sealant is perfect for this because it creates a tough, waterproof bond but stays flexible enough to allow for future removal without wrecking your hull. Put a generous bead around the flange of the thru-hull and a light coat on the first few threads.

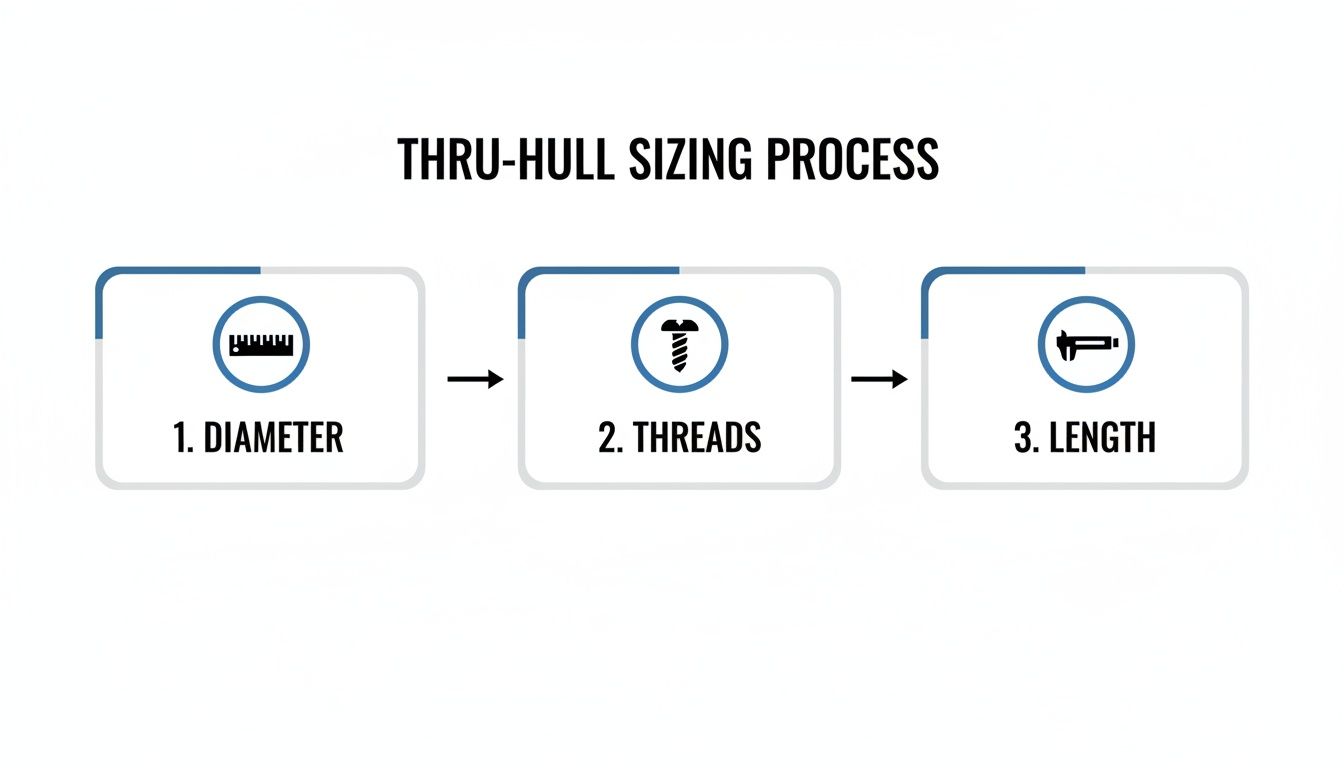

The infographic below shows the key measurements you should have already sorted out before you even get to this stage.

This simple three-step check ensures the fitting you chose has the right diameter, thread type, and length to perfectly match your hose, seacock, and hull thickness.

Tightening and Final Checks

With the sealant applied, push the fitting through the hole from the outside of the hull. From the inside, press the seacock or nut firmly against the backing block and start tightening it by hand. As you snug it up, you should see a nice, even bead of sealant squeezing out around the flange on the outside—that’s the sign of a great seal.

Crucial Tip: Do not overtighten the fitting! The idea is to compress the sealant, not squeeze every last drop out. Cranking down too hard can crack the fitting or even damage your hull. Just tighten it until it's snug, then give it maybe another quarter-turn.

After tightening, clean up the excess sealant that squeezed out for a clean, professional-looking job. Now comes the hard part: waiting. You have to let the sealant cure fully according to the manufacturer's instructions, which could be anywhere from 24 hours to 7 days, before the boat goes back in the water.

A proper cure is everything. Getting these systems right is just as important as knowing your emergency gear, like how a submersible bilge pump can be your last line of defense against taking on water.

Your Guide to Thru-Hull Inspection and Maintenance

The absolute best way to head off a thru-hull emergency is to make routine inspections a non-negotiable part of your time on the boat. It only takes a few minutes of paying attention to spot the subtle warning signs of a potential failure, turning what could be a catastrophe into a simple, manageable repair.

Think of it as a regular health checkup for your boat's circulatory system. This isn't about giving everything a quick glance; it's about being intentional. By breaking down your maintenance into a series of small, easy checks, you can catch problems when they’re small and keep your boat’s most critical connections rock-solid.

What to Look For During Inspection

Your eyes are your single best maintenance tool. Get into the habit of visually inspecting every single thru-hull fitting, seacock, and hose connection whenever you're in the bilge or have the boat out of the water. Keep an eye peeled for these specific red flags.

Remember, the small signs almost always show up before a major failure.

- Corrosion on Bronze: Look for a distinctive pinkish hue on any bronze fittings. This is the classic calling card of dezincification, a nasty process where zinc leaches out of the alloy. What's left behind is a weak, porous copper structure that's just waiting to crack.

- Cracks in Plastic: Give any composite or plastic fittings a close look for hairline stress cracks, paying special attention to the base and the threads. Overtightening, UV damage, or just plain old age can cause these, and they are a clear signal that the fitting's integrity is shot.

- Signs of Weeping: Any hint of moisture, salt creep, or water stains around the base of a fitting or seacock is a major warning. Even the slightest "weep" means the seal has been compromised and needs immediate attention.

A Practical Maintenance Checklist

Beyond just looking, a simple hands-on checklist will give you the full picture of your system's health. Run through these checks at least twice a season—once when you launch and again mid-season.

A sticky or frozen seacock is not an inconvenience; it is a failed piece of safety equipment. If you cannot easily close it in an emergency, it offers no protection at all.

This simple routine can make all the difference:

- Test the Seacock: Every single seacock needs to be opened and closed several times. The handle should move smoothly, without you having to wrestle with it. If it’s stiff, it needs to be serviced. If it’s frozen solid, it must be replaced. No exceptions.

- Inspect the Hoses: Give the hoses connected to your thru-hulls a good squeeze. They should feel firm, not soft or mushy. Look for any cracks, bulges, or chafing, especially right where they connect to the fitting's barb.

- Check the Hose Clamps: Make sure all your hose clamps are high-quality 316 stainless steel. Check that they are snug and free of rust or corrosion. It’s always best practice to use two clamps on every connection below the waterline for built-in redundancy.

The Bigger Picture in Marine Hardware

Regular maintenance isn’t just about protecting your own boat; it’s about being part of a larger culture of safety and good seamanship. Thru-hulls are just one piece of a massive global industry focused on keeping boats safe and reliable.

Across the global marine sector, thru-hull fittings sit inside a much larger but measurable hardware niche: the marine fittings and equipment market. An analysis of this sector estimates it will reach about USD 88.1 billion by 2025, with projected annual growth of 6.1% through 2033. This growth underscores the constant demand for dependable replacement parts like thru-hulls, hoses, and sealants that meet modern safety standards. You can read more about the trends in the marine fittings market to get a sense of the industry's scale.

By dedicating a little bit of time to this simple maintenance playbook, you're not just fixing things—you're actively extending the life of your hardware. You'll ensure your boat's most vulnerable points remain its most secure, giving you real peace of mind every time you leave the dock.

Decoding ABYC Standards for Boating Safety

Following safety standards isn't just about ticking a box. It's about actively preventing a really, really bad day on the water. The American Boat and Yacht Council (ABYC) sets the gold standard here, creating the essential guidelines that good boat builders and mechanics live by. When it comes to thru-hull fittings, their rules are designed to make sure every single hole below your waterline is as bulletproof as possible.

Understanding the "why" behind these rules is what separates a knowledgeable skipper from a novice. The ABYC isn't just throwing out suggestions; their standards come from decades of seeing what holds up and, more importantly, what causes catastrophic failures. Once you get the principles, you'll know how to look at your own boat and see if it truly measures up.

Key ABYC Mandates for Thru-Hulls

At the heart of the ABYC standards are a few non-negotiable rules for any thru-hull that goes through the hull below the waterline. These are all about giving you control and making sure the fitting is structurally sound right where your boat is most vulnerable.

Think of these as the fundamental laws of staying afloat:

- A Seacock Is a Must: Every single thru-hull fitting below the waterline has to have a seacock. This is basically a valve that lets you slam the door shut on incoming water. If a hose splits, this is your first and best line of defense.

- Strong Backing Blocks Are Required: The ABYC insists on a solid backing block on the inside of the hull. This block spreads the stress from the seacock and hoses over a much wider area, stopping the hull from cracking when things get rough.

- You Have to Be Able to Reach It: A seacock you can't get to in a panic is completely useless. The standards demand that all seacocks are easy to reach for both emergency use and regular maintenance without having to tear apart your boat to get to them.

Why These Standards Matter

These rules directly target the most common ways things go wrong. A seacock gives you instant control, turning a potential sinking into a problem you can manage. A backing block reinforces the hull against the constant vibration and stress of a boat underway, preventing the entire fitting from ripping out.

The whole point of the ABYC standards is to make every thru-hull installation "bomb-proof." They require tough materials, solid reinforcement, and quick access. This proactive mindset is what makes a vessel truly seaworthy.

These principles are the bedrock of your boat's integrity, and getting a handle on them is a huge part of being a responsible owner. For a wider view on keeping your boat safe, check out our overview of essential boat safety requirements. Making sure your thru-hulls meet these standards gives you the peace of mind to handle the unexpected and truly enjoy your time on the water.

Still Have Questions About Thru-Hulls?

Even after you get the basics down, the practical, day-to-day side of dealing with thru-hulls can leave you scratching your head. Let's tackle some of the most common questions we get from boat owners, clearing up the confusion so you can feel confident about your boat's plumbing.

How Often Should I Replace My Thru-Hulls?

There isn't a single, hard-and-fast rule here. How long your thru-hulls last really depends on the material they're made of, whether you're in salt or fresh water, and how much you use your boat. That said, having a routine is the best way to stay ahead of trouble.

Here's a good schedule to follow:

- Inspect them annually. Get your eyes on every fitting and look for obvious signs of corrosion, leaks, or wear.

- Give them a thorough check-up every 5 years. This means actually operating the seacocks to make sure they aren't seized and checking the integrity of the attached hoses.

- Budget for replacement every 10-15 years. This is especially true for boats living in saltwater, which is notoriously tough on metals.

Of course, this is just a guideline. If you spot a fitting with serious corrosion (like that dreaded pinkish tint on bronze), find stress cracks in a plastic one, or have a seacock that's completely frozen, replace it immediately. Don't wait, regardless of how old it is.

Can I Install a Thru-Hull in the Water?

Let's make this simple: No. For your own safety and to get a seal that will actually last, all thru-hull work—installing or replacing—has to be done with the boat on the hard. Trying this job while you're in the water is asking for a catastrophic, uncontrolled flood.

Think about it: the marine sealant that creates that critical waterproof bond needs a perfectly clean, dry surface to grab onto. It also needs time to cure properly. You simply can't get that with the boat in the water, which all but guarantees a failed seal sooner or later.

What's the Difference Between a Thru-Hull and a Seacock?

This is a really common mix-up, but the distinction is pretty straightforward. The thru-hull is the actual pipe or fitting that goes through the boat's hull. The seacock is the valve that screws onto the inboard side of that fitting.

Here's an easy way to remember it: The thru-hull is the pipe coming into your house from the street. The seacock is the faucet you use to turn the water on and off. One is the pathway, the other is the control.

Which Sealant Is Best for Installing Thru-Hulls?

You've got to use a top-shelf marine sealant made specifically for below-the-waterline use. And here's a critical pro-tip: steer clear of super-aggressive permanent adhesives like 3M 5200. While it sounds strong, it can make future removal a nightmare, potentially causing serious damage to your hull's fiberglass or gelcoat when you try to pry the old fitting off.

Your best bet is a tough but flexible polyurethane sealant. This gives you a durable, 100% waterproof seal that can handle the harsh marine environment, but it still has enough "give" to allow for removal when it's time to replace the fitting down the road. Our Better Boat Marine Sealant is an ideal choice, offering tenacious adhesion with the flexibility needed for long-term serviceability.

For a rock-solid, waterproof seal that stays flexible for future maintenance, we stand by our Better Boat Marine Sealant. It creates the tenacious bond you need for below-the-waterline security without turning into a permanent problem that could damage your hull.